Buoyancy ascending-descending water decanter and implementation method thereof

A realization method, lift-type technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as complex mechanical lifting devices, power consumption, misoperation, etc., and achieve increased Effects of Structural Complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

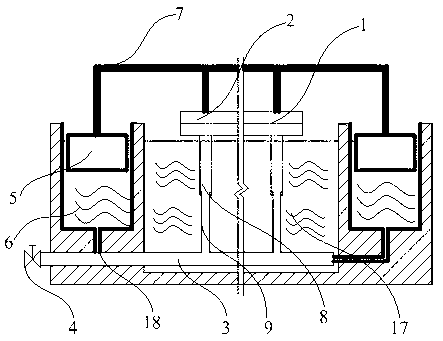

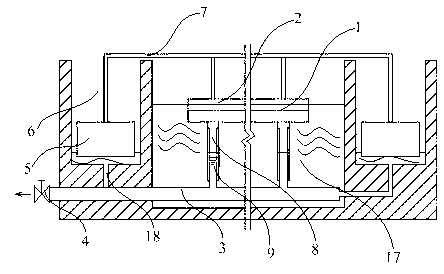

[0057] The buoyancy lifting decanter is mainly composed of the following three parts: the decanting tank, located above the reaction tank, is the direct part of the decanting operation; the floating lifting mechanism is directly connected with the decanting tank to realize the executive mechanism of the decanting tank; the drainage System, during decanting operation, the supernatant liquid in the reaction tank is finally discharged by the drainage system.

[0058] In order to enable those skilled in the art to have a clearer understanding of the above components, it will be described in detail below in conjunction with the accompanying drawings, as figure 1 , 2 As shown, the structure of the decanting tank 2 is similar to that of the existing decanting tank, and a decanting weir 1 is provided on it. During the decanting operation, the supernatant liquid of the reaction tank 17 is introduced into the decanting tank 2 through the decanting weir 1.

[0059] Floating lifting mech...

Embodiment 2

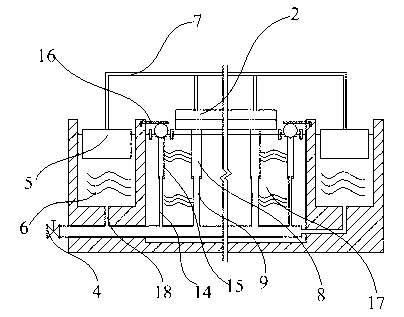

[0065] Such as image 3 , 4 As shown, the difference between this embodiment and Embodiment 1 is that, on the basis of the structure of Embodiment 1, there is also a replenishment valve connected with the drain main pipe 3, and the replenishment valve includes a telescopic replenishment pipe, a floating ring 10, a decanter Water plate 12, floating spool 13 and limit plate 16 five parts.

[0066] The telescopic water replenishment pipe communicates with the drainage main pipe 3, and its structure is similar to that of the telescopic drainage branch pipe. Composition, the connection method of the water replenishment branch pipe 14 and the water replenishment casing 15 is an existing mature technology, therefore, this embodiment will not repeat them.

[0067] The structure of the floating ring 10 is as Figure 5 , 6 As shown, it has a certain thickness, and the decanting plate 12 is arranged at the lower end of the floating ring 10, and the two are connected by several strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com