Preparation method for ultralong nanowire toughed ceramic coating

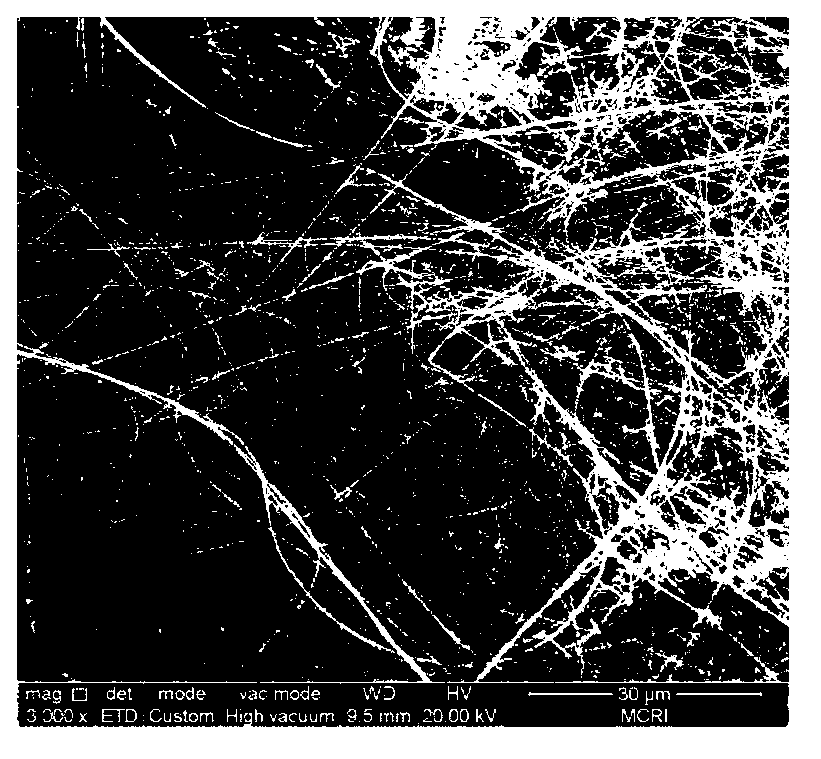

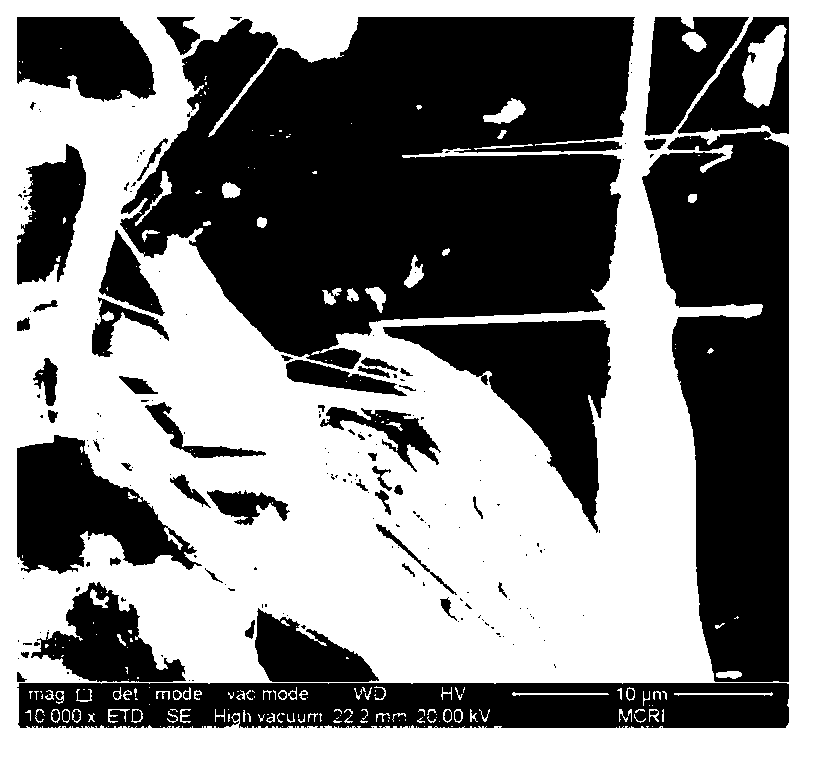

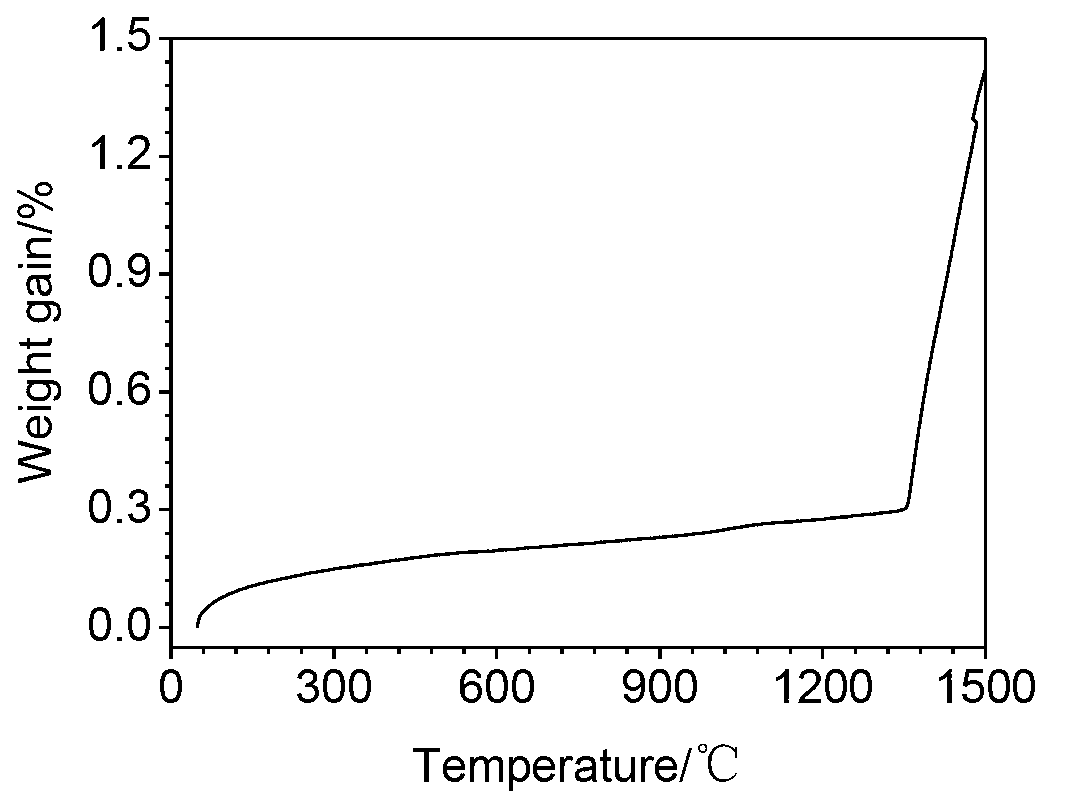

A nanowire toughening and ceramic coating technology, which is applied in the field of preparation of ultra-long nanowire toughened ceramic coatings, can solve the problems of easy cracking of the coating, limited toughening effect, low aspect ratio, etc. Oxidation ability, reduced cracking tendency, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0032] Weigh 60g of Si powder, 15g of SiC powder, 15g of C powder, 10g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 2 hours to obtain embedding powder.

[0033] Put the above 1 / 4 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 4 embedding powder, so that the powder evenly covers the C / C composite material, then put the graphite crucible into the high-temperature reaction sintering furnace, then raise the furnace temperature to 2200°C, the heating rate is 10°C / min, then keep it warm for 1h, then turn off the power and naturally cool to room temperature, and pass Ar in the...

Embodiment 2

[0037] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0038] Weigh 72g of Si powder, 10g of SiC powder, 11g of C powder and 7g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 3 hours to obtain embedding powder.

[0039] Put the above 1 / 4 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 4 embedding powder, so that the powder evenly covers the C / C composite material, then put the graphite crucible into the high-temperature reaction sintering furnace, then raise the furnace temperature to 2100°C, the heating rate is 7°C / min, then keep it warm for 2h, then turn off the power and naturally cool to room temperature, and pass Ar in th...

Embodiment 3

[0043] The C / C composite material was polished and polished sequentially with No. 400, No. 800 and No. 1000 sandpaper respectively, washed with absolute ethanol, and dried in an oven for later use.

[0044] Weigh 85g of Si powder, 5g of SiC powder, 7g of C powder, 3g of Al 2 o 3 pink. Place in a ball mill jar, put agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 4 hours to obtain embedding powder.

[0045] Put the above 1 / 4 embedding powder into the graphite crucible, put the prepared C / C composite material, and then put the above 1 / 4 embedding powder, so that the powder evenly covers the C / C composite material , and then put the graphite crucible into a high-temperature reaction sintering furnace, then raise the furnace temperature to 2000°C with a heating rate of 5°C / min, then keep it warm for 2h, then turn off the power and cool it down to room temperature naturally, and use A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com