Self-adhesion laser micro-propelling transmission target ablation material, preparation method thereof and target belt prepared by material

A technology of ablation materials and micro-propulsion, which is applied in the direction of attacking equipment and compressed gas generation, can solve the problems of reducing laser energy utilization rate, increasing manufacturing process, affecting light transmittance, etc., to improve laser energy utilization rate and avoid Thorough effect of absorption and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

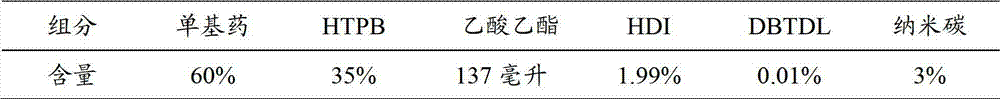

[0037] Example 1 Preparation of self-adhesive laser micro-propelled transmission target ablation material mixture and its target belt

[0038] Prepare ablative material in the following proportions:

[0039] 60 energy supply materials,

[0040] Improve bonding material 35 parts,

[0041] Additives 5 parts.

[0042] (1) Prepare energy-supplying material, cohesiveness-improving material and additives according to the above ratio, and dissolve them with solvent respectively to obtain energy-supplying material solution, cohesiveness-improving material solution and additive solution;

[0043] Among them, the energy-supplying material: 8 grams of the single-base drug was dissolved in 120 milliliters of ethyl acetate, and stirred evenly with a stirrer after standing for 24 hours.

[0044] Adhesion-improving material: 4.6 g of HTPB was dissolved in 10 ml of ethyl acetate.

[0045] Additives: 0.7 g nanocarbon dissolved in 5 ml ethyl acetate, 0.2 ml hexamethylene diisocyanate (HDI) di...

Embodiment 2

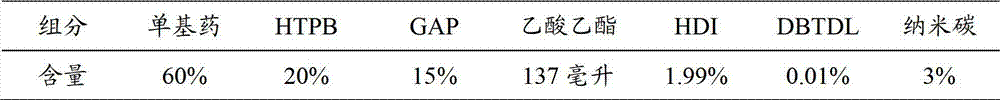

[0055] Example 2 Preparation of self-adhesive laser micro-propelled transmission target ablation material mixture and its target belt

[0056] Prepare ablative material in the following proportions:

[0057] 60 energy supply materials,

[0058] Improve bonding material 35 parts,

[0059] Additives 5 parts.

[0060] (1) Prepare energy-supplying material, cohesiveness-improving material and additives according to the above ratio, and dissolve them with solvent respectively to obtain energy-supplying material solution, cohesiveness-improving material solution and additive solution;

[0061] Among them, the energy-supplying material: 8 grams of the single-base drug was dissolved in 120 milliliters of ethyl acetate, and stirred evenly with a stirrer after standing for 24 hours.

[0062] Material for improving adhesion: after mixing 2.3 grams of HTPB and 2.3 grams of GAP evenly, dissolve them in 10 ml of ethyl acetate.

[0063] Additives: 0.7g nanocarbon dissolved in 5ml ethyl a...

Embodiment 3

[0073] Example 3 Preparation of sticky laser micro-propelled transmission target ablation material mixture and its target belt

[0074] Prepare ablative material in the following proportions:

[0075] 90 energy supply materials,

[0076] 5 parts of adhesive improvement material,

[0077] Additives 5 parts.

[0078] (1) Prepare energy-supplying material, cohesiveness-improving material and additives according to the above ratio, and dissolve them with solvent respectively to obtain energy-supplying material solution, cohesiveness-improving material solution and additive solution;

[0079] Among them, the energy-supplying material: 8 grams of the single-base drug was dissolved in 120 milliliters of ethyl acetate, and stirred evenly with a stirrer after standing for 24 hours.

[0080] Material to improve adhesion: 0.5 g of HTPB was dissolved in 5 ml of ethyl acetate.

[0081] Additives: 0.4 g nanocarbon dissolved in 2 ml ethyl acetate, 0.3 ml hexamethylene diisocyanate (HDI) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com