Organosilicon polyimide insulation adhesive for LED

A silicon polyimide and adhesive technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor adhesion of conductive adhesives and small chip thrust, and achieve excellent bonding strength, The effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

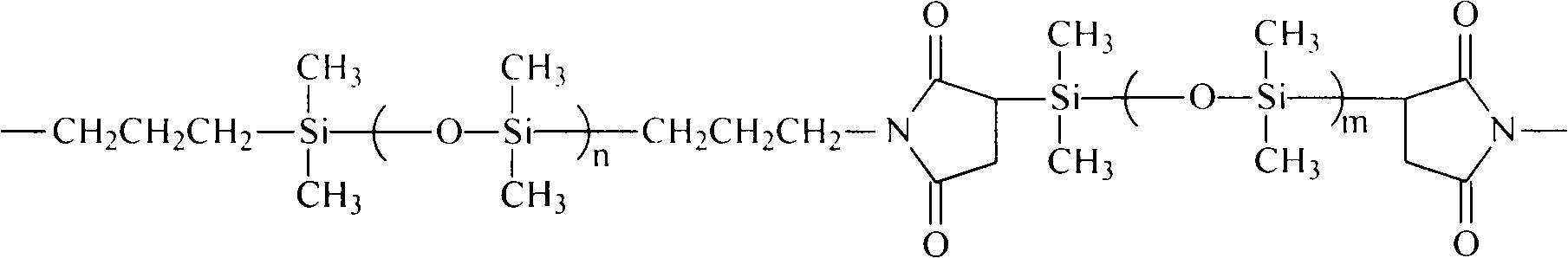

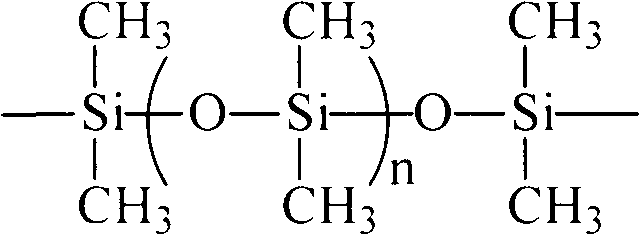

[0042] As shown in Table 1, mix amino-terminated silicone oil SiMNH, anhydride-terminated silicone oil SiMDH and polyamino-silicone oil SinNH in a certain proportion, stir at room temperature for 6 hours, then add silicon dioxide, titanium dioxide and interface reinforcing agent silane coupling agent , using a three-roll mill to grind three times to obtain a silicone polyimide insulating adhesive.

[0043] Table 1. Components of silicone polyimide insulating adhesive

[0044]

[0045] DAGA 4000 thruster was used to test the properties of the silicone polyimide insulating adhesives for LEDs obtained in Examples 1-4, and the results are shown in Table 2.

[0046] Table 2. Properties of silicone polyimide insulating adhesive

[0047]

[0048] It can be seen from the results in Table 2 that the refractive index of the silicone polyimide insulating adhesive for LED prepared by the method of Examples 1 to 4 is 1.48 to 1.49, the glass transition temperature is 102 to 112°C, an...

Embodiment 5~8

[0050] As shown in Table 3, mix amino-terminated silicone oil SiMPNH, anhydride-terminated silicone oil SiMPDH and polyamino-silicone oil SinNH in a certain proportion, stir at room temperature for 8 hours, then add silicon dioxide, titanium dioxide and interface reinforcing agent silane coupling agent , using a three-roll mill to grind three times to obtain a silicone polyimide insulating adhesive.

[0051] Table 3. Components of silicone polyimide insulating adhesive

[0052]

[0053] DAGA 4000 thruster was used to test the properties of the silicone polyimide insulating adhesives for LEDs obtained in Examples 5-8, and the results are shown in Table 4.

[0054] Table 4. Properties of silicone polyimide insulating adhesive

[0055]

[0056] It can be seen from the results in Table 4 that the refractive index of the silicone polyimide insulating adhesive for LEDs prepared by the method of Examples 5-8 is 1.53, the glass transition temperature is 113-121°C, and the thrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thrust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com