Preparation method of indocalamus leaf volatile oil and application of volatile oil in cigarette

A technology of sap bamboo leaves and volatile oil, which is applied in the field of preparation of volatile oil of sap bamboo leaves, can solve the problems such as no report, lag of sap bamboo leaves, etc., and achieves the effects of rich aroma, many changes, and improved aroma quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

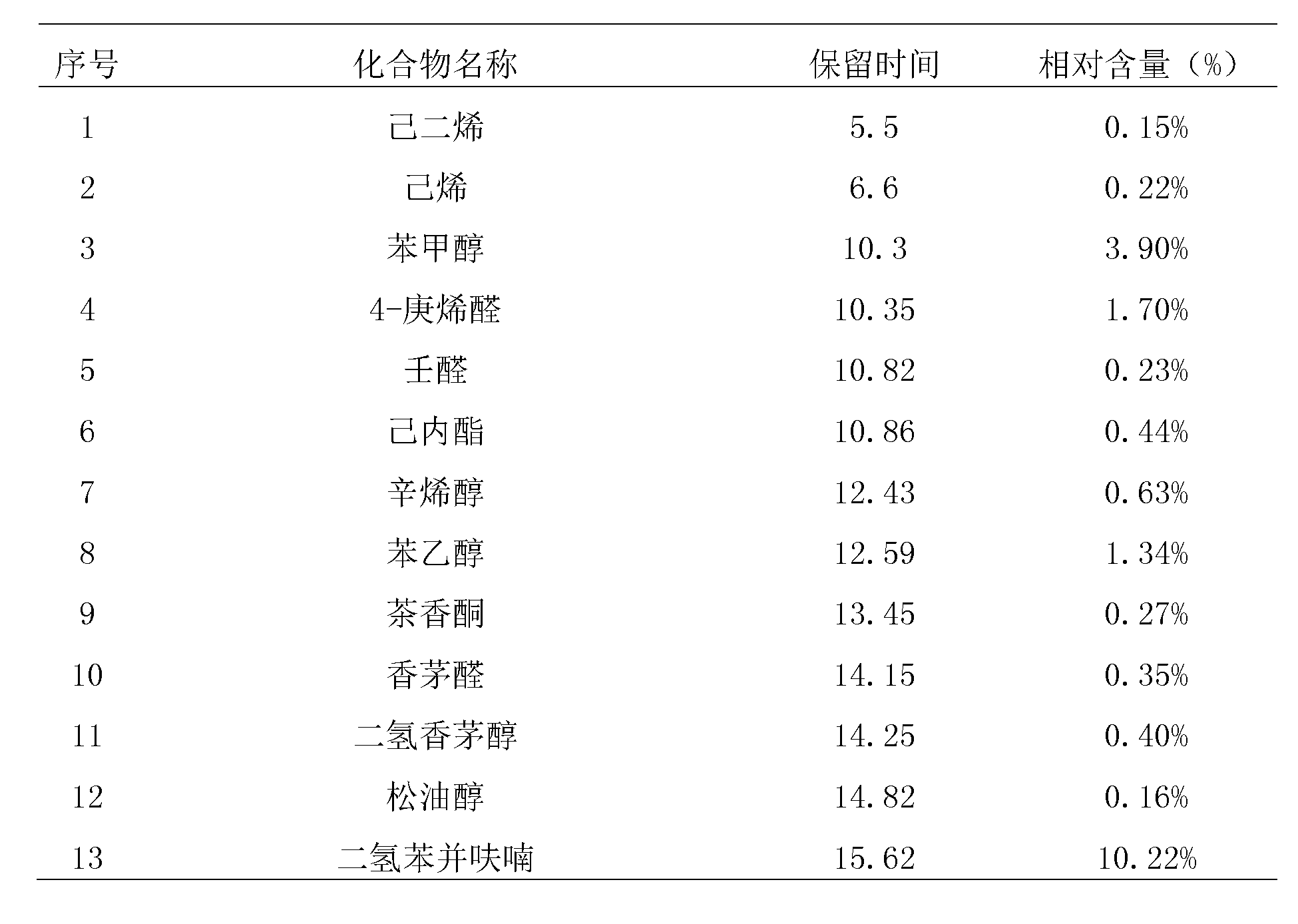

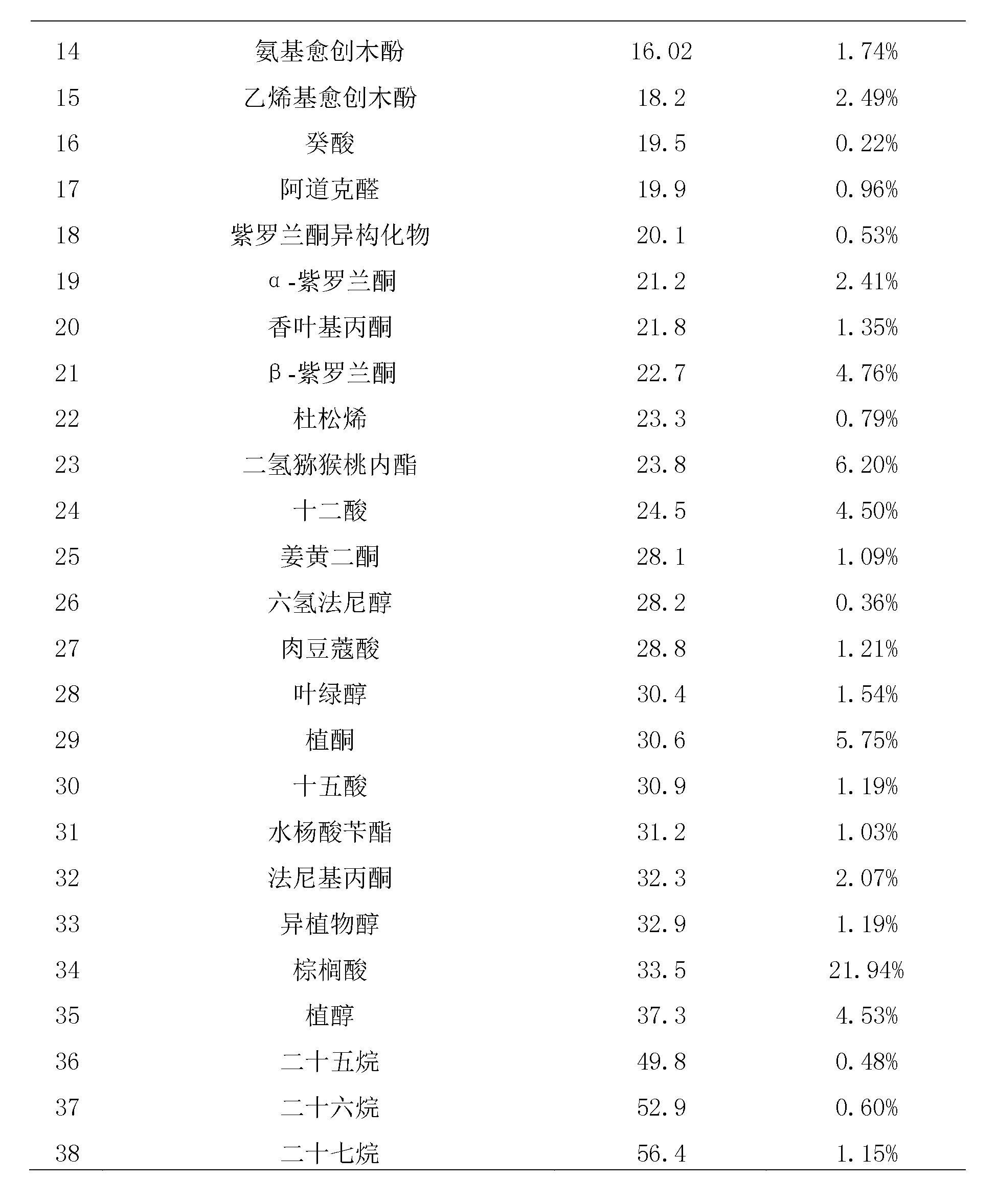

Examples

Embodiment 1

[0034] Embodiment 1: steam distillation method, carry out according to the following steps:

[0035] A, the bamboo leaf raw material is cleaned and removed, dried and pulverized, and pulverized into fragments of about 30 orders;

[0036] B, after mixing the bamboo leaf fragments with water in a ratio of 1:2-10 by mass, add it to the steam distillation device, and soak it for 12-18 hours at normal temperature;

[0037] C. Using steam distillation, the distillation temperature is 110-130° C., and the distillation time is 6-10 hours. The oil-water mixture obtained by distillation is separated from oil and water to obtain light yellow-green clear and transparent volatile oil A.

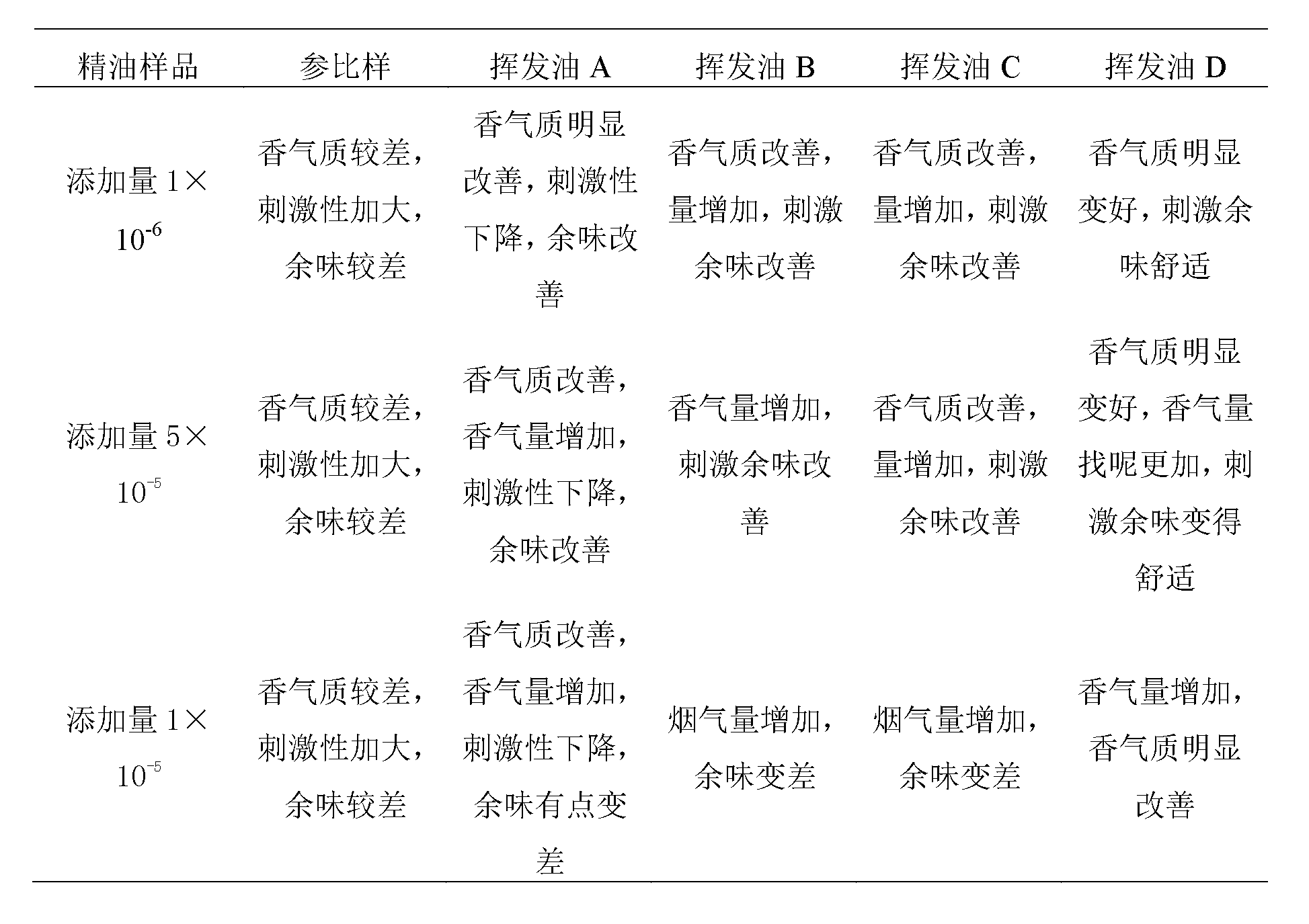

[0038] Dissolve the above-mentioned volatile oil A of bamboo leaves in 100 times of 95% ethanol and dilute it. The diluted volatile oil ethanol solution is added to shredded cigarette tobacco as a tobacco material liquid, and the texture and richness of aroma of the produced cigarette product It has incr...

Embodiment 2

[0040] The water vapor-organic solvent preparation method of the bamboo leaf volatile oil is carried out according to the following steps:

[0041] A, the bamboo leaf raw material is cleaned and removed, dried and pulverized, and pulverized into fragments of about 30 orders;

[0042] B, after mixing the bamboo leaf fragments with water in a ratio of 1:2-10 by mass, add it to the steam distillation device, and soak it for 12-18 hours at normal temperature;

[0043] C. Put the mixture of water and bamboo leaves into a distillation pot for distillation, the distillation temperature is 110-130°C, and the distillation time is 2-5 hours; add auxiliary solvent ether to another distillation pot and heat it to 45°C to obtain ether vapor. The weight of the added ether is 1-5 times that of the bamboo leaves; the ether vapor and the water vapor entraining the volatile oil of the bamboo leaves are mixed and cooled in the collection tank to obtain a mixed solution;

[0044] D. The mixed so...

Embodiment 3

[0048] The water vapor-organic solvent preparation method of the bamboo leaf volatile oil is carried out according to the following steps:

[0049] A, the bamboo leaf raw material is cleaned and removed, dried and pulverized, and pulverized into fragments of about 30 orders;

[0050] B, after mixing the bamboo leaf fragments with water in a ratio of 1:2-10 by mass, add it to the steam distillation device, and soak it for 12-18 hours at normal temperature;

[0051] C. Put the mixture of water and bamboo leaves into a distillation tank for distillation, the distillation temperature is 110-130°C, and the distillation time is 2-5 hours; add auxiliary solvent petroleum ether to another distillation tank and heat it to obtain petroleum ether vapor. The weight of adding petroleum ether is 1-5 times of the bamboo leaves; the petroleum ether vapor and the water vapor entraining the volatile oil of the bamboo leaves are mixed and cooled in the collection tank to obtain a mixed solution;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com