Automatic sampling system for radioactive gas-carrying discharge substances

A technology for automatic sampling and effluent, applied in the direction of sampling devices, etc., it can solve the problem that continuous sampling or regular sampling monitoring is infeasible, cannot truly and objectively reflect the emission source items of chimney airborne substances, and cannot reflect the working conditions of airborne substances. and other issues to achieve a practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

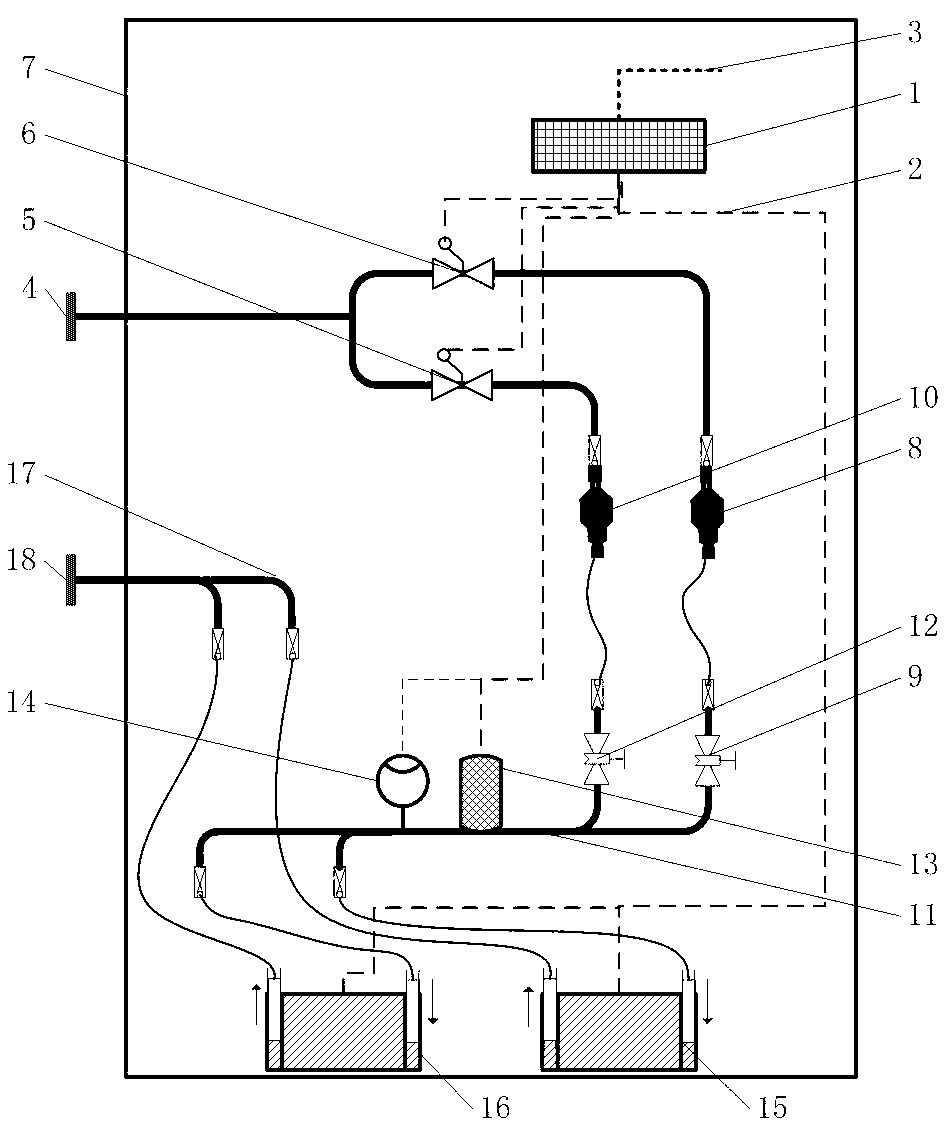

[0018] figure 1 It is a schematic diagram of the structure of the present invention. exist figure 1 Among them, the radioactive airborne effluent automatic sampling system of the present invention comprises an automatic control unit 1, a first solenoid valve 6, a second solenoid valve 5, a first aerosol and iodine sampling head 8, a second Aerosol and iodine sampling head 10, mass flow meter 13, pressure gauge 14, pump I15 and pump II16 also include the inlet pipe joint 4 and exhaust pipe joint 18 that are arranged on the outside of sampling cabinet 7; Its connection relationship is, is arranged on The inlet pipe joint 4 outside the sampling cabinet 7 is connected with the first solenoid valve 6 and the second solenoid valve 5 respectively by the gas pipe; the first solenoid valve 6 is connected with the first aerosol and an end of the iodine sampling head 8 by the gas pipe, The other end of sol and iodine sampling head 8 is connected with an end of first flow regulating val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com