Integrated detector for slurry viscosity and rock debris granularity

A detector, an integrated technology, applied in the field of detection, can solve the problem of not being able to meet the real-time measurement and timely utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

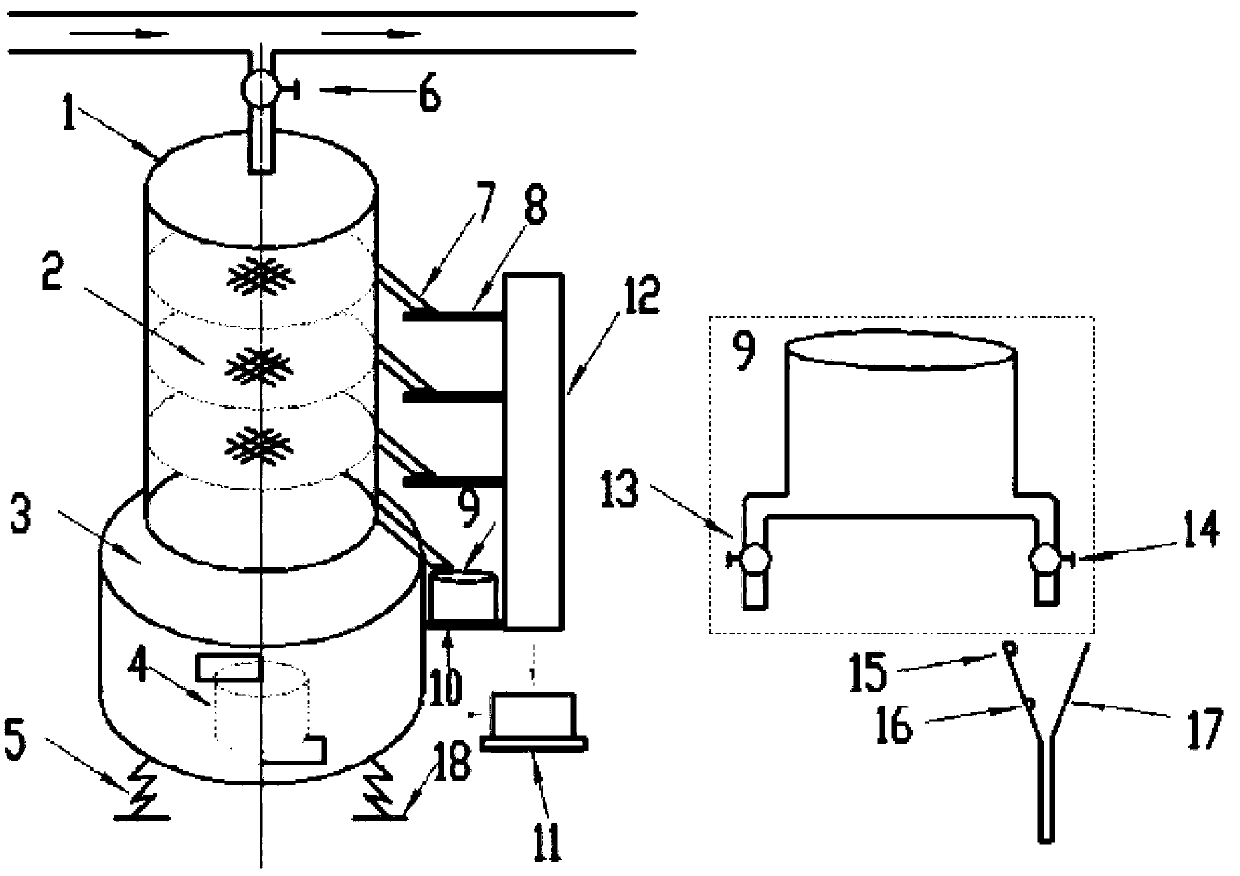

[0023] As shown in the figure, screens 2 of different meshes such as 60 mesh, 80 mesh, 120 mesh, and 180 mesh are respectively installed in the housing 1 of the multi-layer particle size separation screen. Only three layers are shown in the figure, but the implementation may not be limited to three floors.

[0024] The virtual signal analysis processor 11 based on computer software and hardware technology is directly related to the integrated box 12 that installs various weighing, liquid level sensing and relays, analyzes and displays various curves, and installs various weighing devices and corresponding analysis The integrated box 12 that processes and displays relevant data curves obtains all sensor signals for data collection, and then sends the relevant data to the virtual signal analysis processor 13 for centralized processing and analysis to obtain various required results. The relay switching signals output by the processor in sequence are connected to the solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com