Rat-proof and termite-proof coaxial cable for grounding ultra-high voltage transmission line

A technology for transmission lines and coaxial cables, applied in coaxial cables, circuits, power cables with shielding layers/conductive layers, etc., can solve problems such as uneven electric fields of cables, achieve excellent electrical and physical properties, and design conductor structures Reasonable and convenient conductor connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

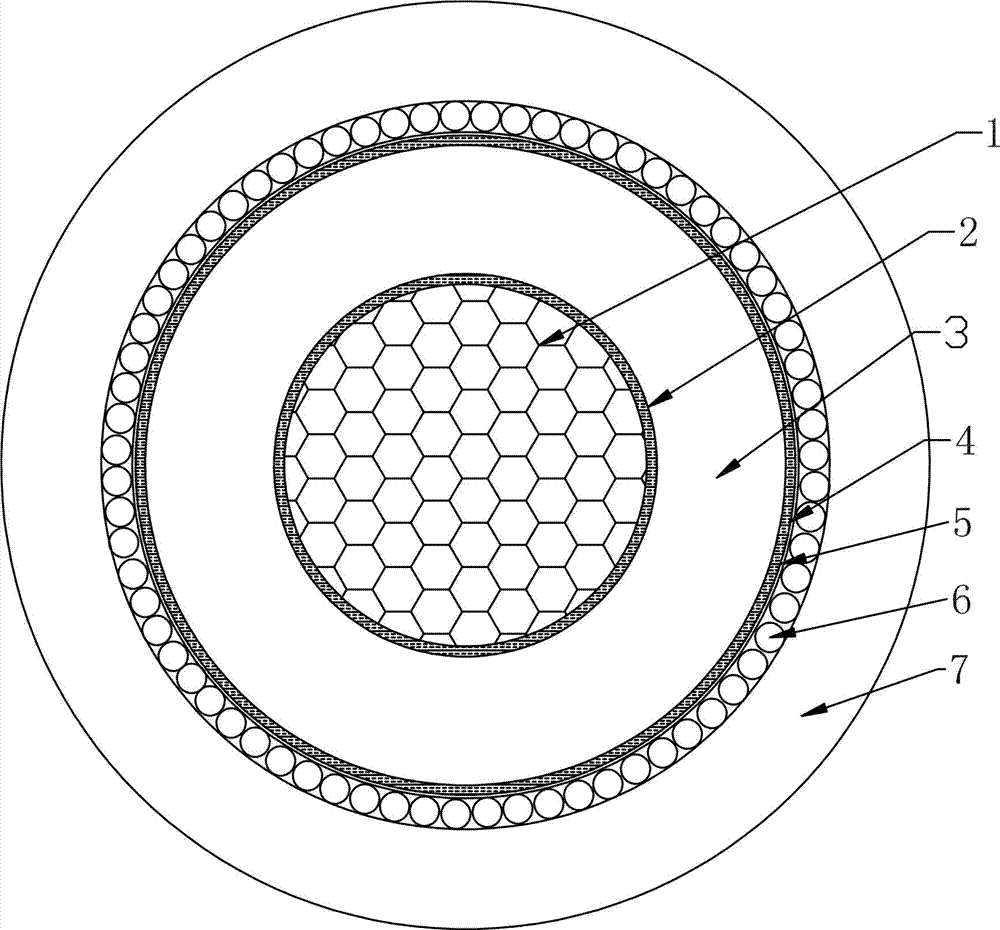

[0021] Such as figure 1 As shown, a rodent-proof and termite-proof coaxial cable for grounding ultra-high voltage transmission lines, the inner copper conductor 1 is wrapped with a conductor shielding layer 2, an insulating layer 3, an insulating shielding layer 4, a semiconductor tape layer 5, and an outer copper conductor Layer 6 and outer jacket layer 7.

[0022] The insulating layer 3 is a cross-linked polyethylene insulating layer.

[0023] The outer sheath layer 7 is a high density polyethylene sheath layer.

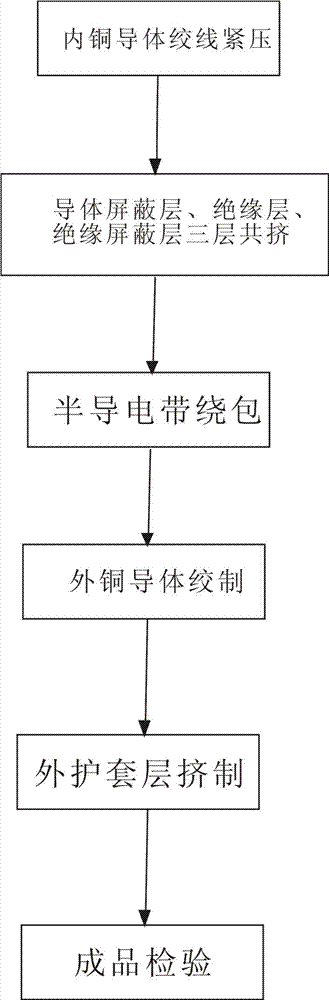

[0024] The production process of the present invention is as figure 2 As shown, the key points for each step are as follows:

[0025] 1. Inner copper conductor 1

[0026] The inner copper conductor 1 is composed of bare annealed copper wires conforming to GB / T3956 (purity of copper ≥ 99.97%). In the manufacturing process of the cable conductor, the oxygen-free copper rod is firstly manufactured by the imported up-drawing production line, and the single wire i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com