A method for manufacturing a small circuit breaker integrated static contact bridge

A technology of a small circuit breaker and a manufacturing method, which is applied in the manufacturing of emergency protection devices, circuits, electrical components, etc., can solve the problems of high production costs, large investment in human and material resources, and increase in working temperature, and save energy and human and material resources. The effect of resource, production cost reduction, and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: (the static contact bridge is copper inlaid with silver)

[0024] 1. The surface treated T 2 The copper strip is grooved in the direction of extension at 3 / 4 of the bandwidth, and the groove width is 3.9mm;

[0025] 2. Lay the surface-treated silver tape matching the groove width of 3.9mm in the groove;

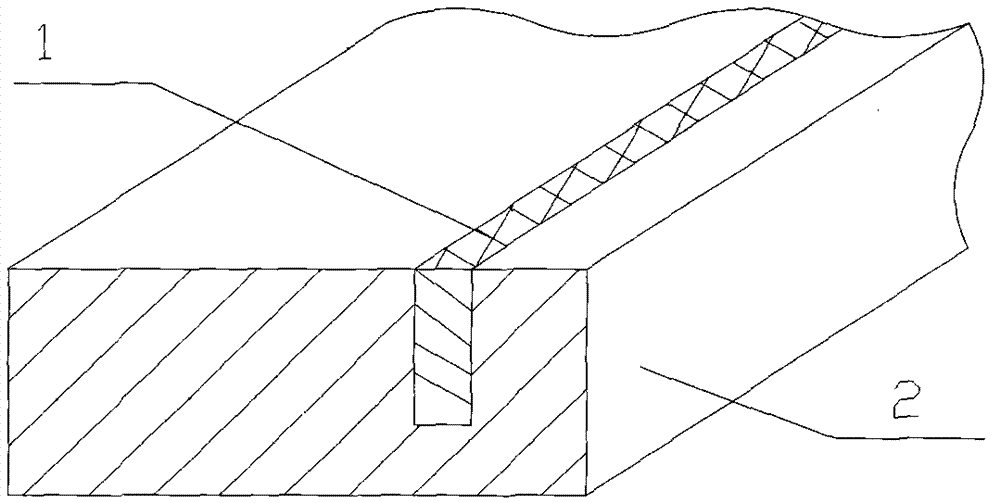

[0026] 3. Use argon arc welding to seal the silver strip laid in the groove and the edge of the groove to obtain the inlaid blank strip body (such as figure 1 );

[0027] 4. After surface-treating the blank strip body of 3, put it into an electric furnace with a furnace temperature of 790°C and protect it with hydrogen for 2 hours;

[0028] 5. Continuously hot-roll the heated blank strip body in 4 under the protection of argon gas and induction heating to obtain a blank strip with a thickness of 110% of the required size (the required size is 1.20mm) ;

[0029] 6. Diffusion annealing is carried out on the primary strip of 5 to eliminate stress at a t...

Embodiment 2

[0032] Embodiment 2: (the static contact bridge is copper inlaid with silver alloy)

[0033] 1. The surface treated T 3 The copper strip is grooved in the direction of extension at 4 / 5 of the bandwidth, and the groove width is 2.9mm;

[0034] 2. Lay the surface-treated silver tape matching the groove width of 2.9mm in the groove;

[0035] 3. Use argon arc welding to seal the silver alloy strip laid in the groove and the edge of the groove to obtain an inlaid blank strip body (such as figure 1 );

[0036] 4. After the surface treatment of the blank body of 3, put it into an electric furnace with a furnace temperature of 820 ° C and protect it with argon gas and heat it for 2.5 hours;

[0037] 5. Continuously hot rolling the heated blank strip body in 4 under the protection of argon gas and induction heating to obtain a blank strip with a thickness of 115% of the required size;

[0038] 6. Diffusion annealing is carried out on the primary strip of 5 to eliminate stress, the ...

Embodiment 3

[0041] Embodiment three: (the static contact bridge is brass inlaid with silver)

[0042] 1. The surface-treated H 62 For the brass strip, a groove is made in the extension direction of 3 / 4 of the bandwidth, and the groove width is 3.7mm;

[0043] 2. Lay the surface-treated silver tape matching the groove width of 3.7mm in the groove;

[0044] 3. Use argon arc welding to seal the silver strip laid in the groove and the edge of the groove to obtain the inlaid blank strip body (such as figure 1 );

[0045] 4. After surface-treating the blank strip body of 3, put it into an electric furnace with a furnace temperature of 810°C and protect it with hydrogen for 2 hours;

[0046] 5. Continuously hot-roll the 4 heated blank strips under the protection of argon gas and induction heating to obtain a blank strip with a thickness of 120% of the required size;

[0047] 6. Diffusion annealing is carried out on the primary strip of 5 to eliminate stress. The temperature of the electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com