Solar cell chip and manufacturing method thereof

A solar cell and chip technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increasing the contact resistance between electrodes and semiconductor layers, limiting the contact area between electrodes and semiconductor layers, shortening the circulation distance, and improving sunlight utilization rate, improve the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

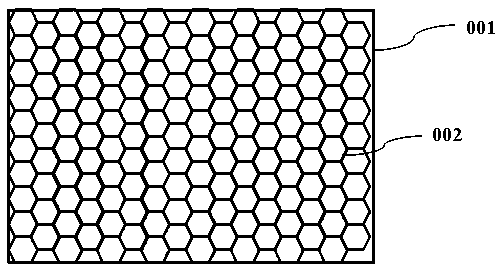

[0031] The following embodiments disclose a high-power concentrating solar cell chip and its manufacturing method. It uses transparent conductive materials to form ohmic contact with the battery semiconductor layer in a large area. Specifically, a grid-shaped metal nanometer is formed on the surface of the battery semiconductor layer Electrodes, and then cover the transparent conductive layer, so that the metal nano-electrodes are embedded in the transparent conductive layer, which greatly improves the conductivity of the conductive layer.

[0032] The following will be further described in conjunction with the implementation of the present invention, but the protection scope of the present invention should not be limited thereby.

[0033] Such as figure 1 and figure 2 As shown, a high-power concentrated solar cell epitaxial wafer 001 is provided. Taking the GaInP / GaAs / Ge triple-junction solar cell as an example, the epitaxial layer of the GaInP / GaAs / Ge triple-junction cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com