Two-way switch tube-based current source type two-way multi-pulse converter

A technology of bidirectional converter and current source type, which is applied in the field of current source type bidirectional multi-pulse converter and power electronic conversion, and can solve the problems that energy cannot be transmitted bidirectionally, and achieve volume reduction, volume reduction, and system reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

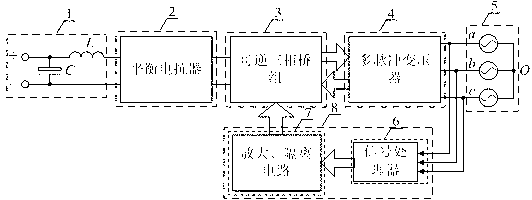

[0035] attached figure 1 A schematic structural diagram of the current source type bidirectional multi-pulse converter based on the bidirectional switching tube of the present invention is given.

[0036] The invention comprises a DC side circuit (1), a reversible three-phase bridge group (3), a multi-pulse transformer (4), a three-phase AC power supply (5) and a control circuit (8). When the system is a 12- or 24-pulse bidirectional converter, it is best to connect a balance reactor (2) between the DC side circuit (1) and the reversible three-phase bridge group (3) to realize the current of each three-phase bridge current sharing.

[0037] Multi-pulse transformers can use various types of transformers with corresponding pulse numbers in the corresponding structures of 6, 12, 18, and 24-pulse bidirectional converters.

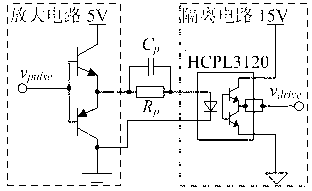

[0038] The reversible three-phase bridge group can be composed of a basic switching unit composed of a bidirectional thyristor, a parallel connection of two r...

Embodiment 2

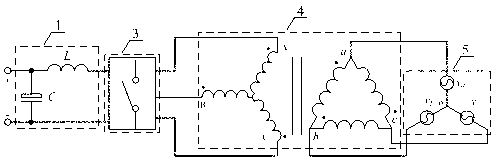

[0045] Such as image 3 As shown, the structure of the isolated 6-pulse bidirectional converter in the present invention. The balance reactor (2) is not connected between the DC side circuit (1) and the reversible three-phase bridge group (3). The midpoint is sequentially connected with the corresponding interface of the multi-pulse transformer.

Embodiment 3

[0047] The structure of the self-coupling type 12-pulse bidirectional converter of the present invention is as follows Figure 4 shown. 10

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com