Method and device for determining model parameters to control modules of a steam power plant

A technology of model parameters and steam generators, which is applied in the direction of steam engine devices, steam generation, control systems, etc., which can solve the unavoidable, inaccurate estimated values of boiler time constants stored in time constants, and the inability to rule out the decline of control quality over time, etc. problems to achieve high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

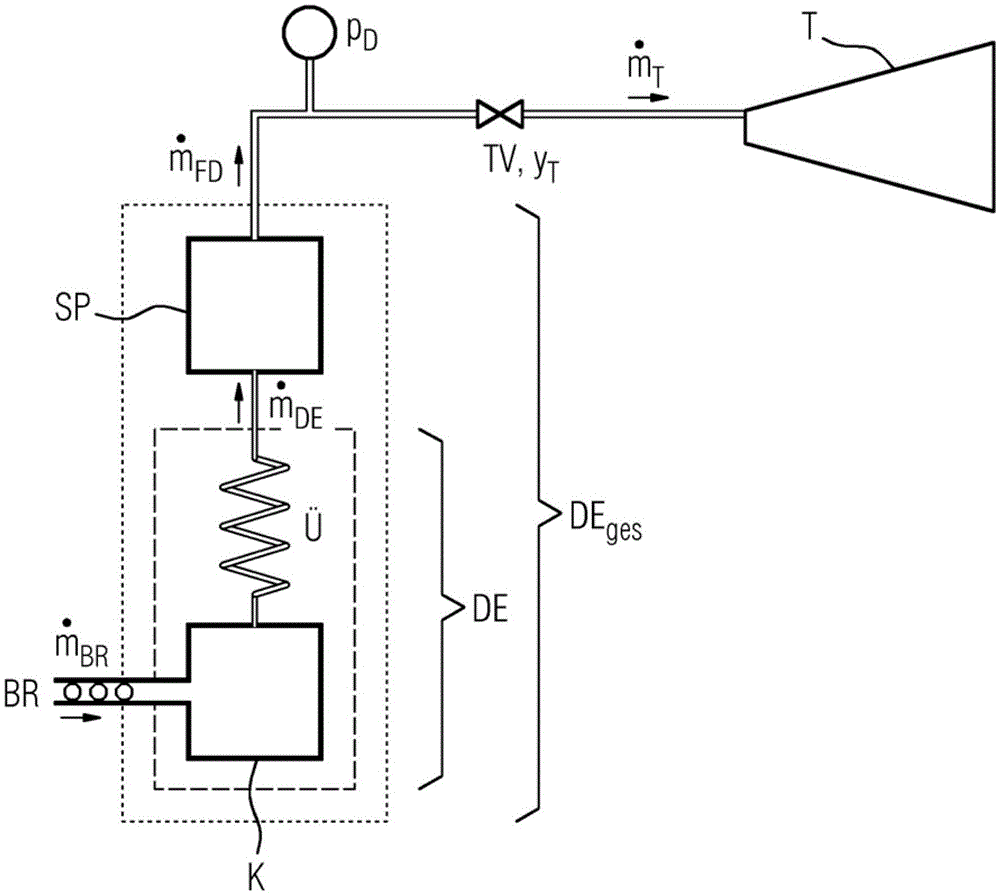

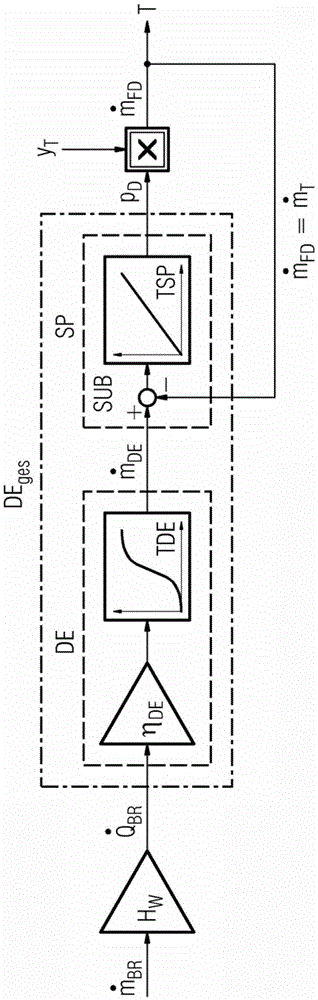

[0023] Figure 1 is used to clarify the dynamic process of steam generation and explain two model parameters: boiler time constant TDE and storage time constant TSP.

[0024] exist Figure 1A A block diagram of the steam generator is shown in simplified form in . The combustion chamber of boiler K is supplied with fuel BR at its inlet, wherein the fuel can be, for example, coal pulverized into pulverized coal in a coal pulverizer. Fuel can be measured here material flow. The corresponding thermal power of the fuel Corresponds to the material flow corrected for the heating value HW of the fuel. Fuel is burned inside the boiler K. In order to generate steam, the feed water conveyed in the pipes in the walls of the steam generator is heated and evaporated. through the superheater The piping system delivers this steam to the turbine valve TV. steam generation DE ges The overall process is ideally divided into two partial processes: the actual steam generation DE and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com