Method for prolonging cheese shelf life by irradiation technology

An irradiation technology and a shelf life technology, which is applied in the field of prolonging the shelf life of cheese, can solve the problems of poor hygiene quality of raw milk, large differences in residual bacterial count, cytoplasmic enzymes, and difficulty in strict control of total bacterial count and somatic cell count. Less pollution, faster treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The packaged cheese is irradiated with a dose of 0.1-10KGy.

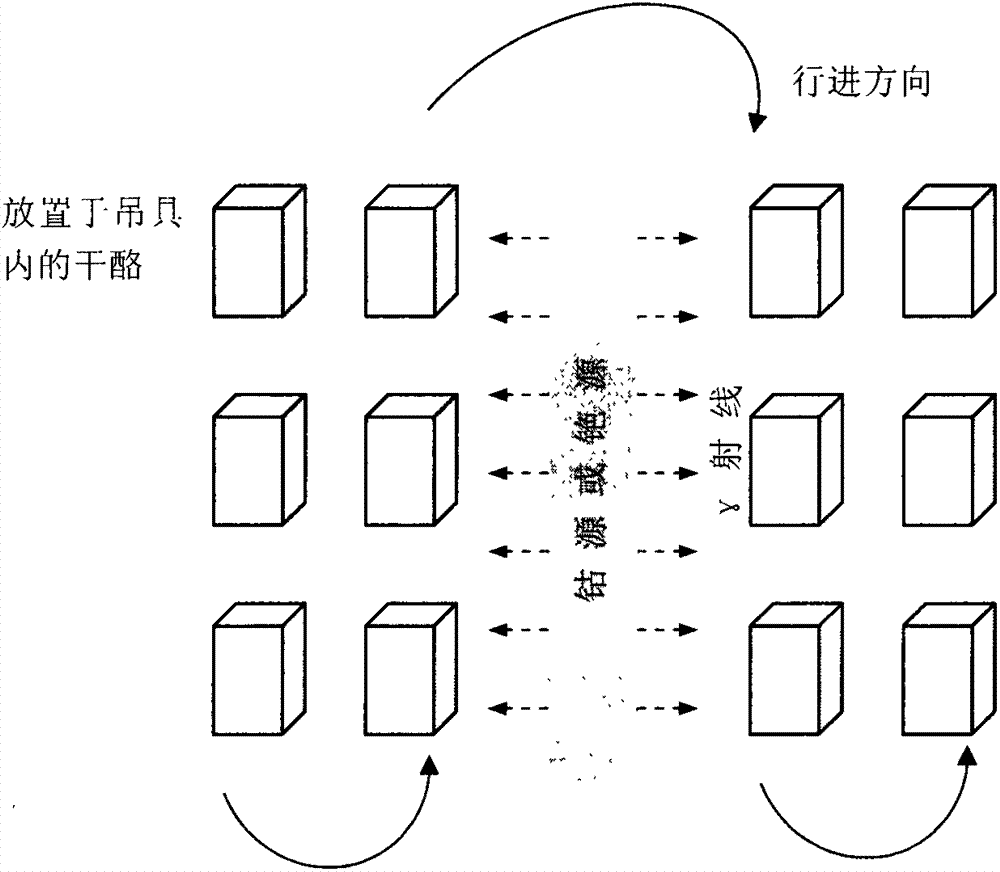

[0015] When using cobalt source or cesium source for irradiation, the irradiation process is as follows: figure 1 shown. The packaged cheese is placed in the sling, travels with the sling between the cobalt source or the cesium source, and receives the uniform irradiation of the specified dose of gamma rays;

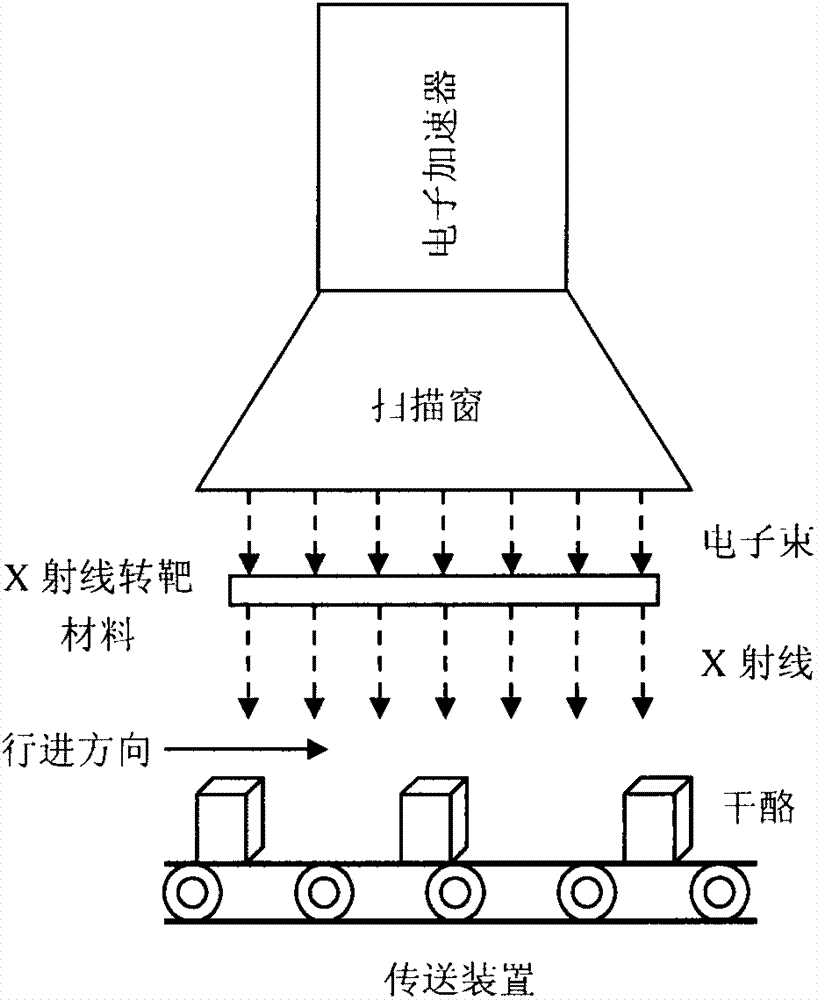

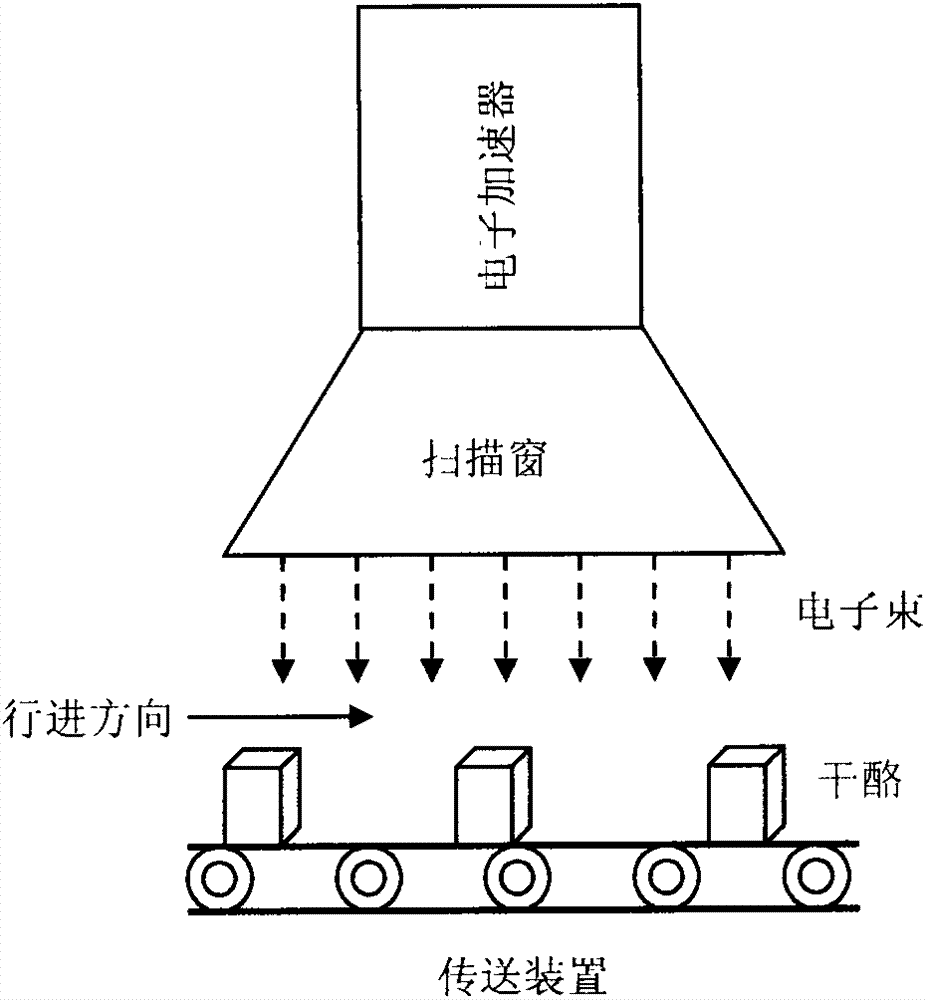

[0016] When using a machine source for irradiation, there are two situations as follows: When using an X-ray target, the machine source generates X-rays, and the irradiation process is as follows: figure 2 As shown; when no X-ray target is used, the machine source generates an electron beam, and the irradiation process is as follows image 3 As shown in the figure, the packaged cheese is placed on the conveying device, and is uniformly irradiated with a prescribed dose of electron beam or X-ray along with the conveying device.

[0017] After irradiation, the shelf life of cheese can be extended by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com