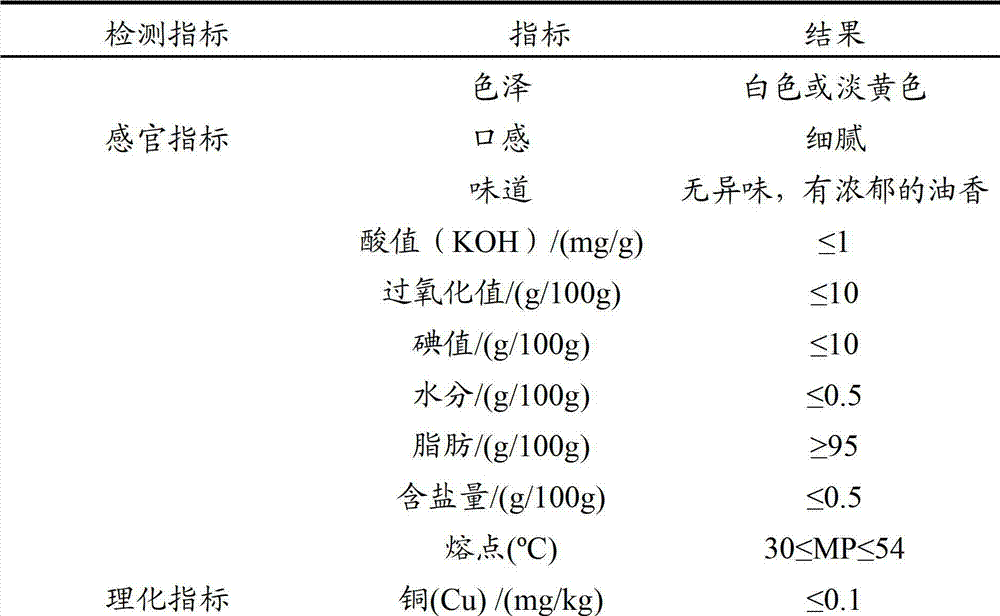

Healthy and nutrient grease special for freezing and preparation method thereof

A nutritional and oil-based technology, applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of women suffering from type 2 diabetes, poor product quality, and brain function decline, and achieve good oxidation effect and good versatility , the effect of lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials were weighed according to the following formula (weight): palm stearin 95g, camellia oil 5g, glyceryl monostearate 0.5g, Span 800.5g, butylated hydroxyanisole 0.003g, potassium sorbate 0.06g.

[0030] Preparation method of special oil for freezing: heating palm stearin to 70°C for melting; cooling slightly after melting completely, adding camellia oil and butyl hydroxyanisole to 70°C, fully stirring and mixing the two; adding monostearic acid Glycerides, Span 80 and Potassium Sorbate are emulsified under heating, the emulsification speed is 700 rpm, the emulsification temperature is 70°C, and the emulsification time is 10 minutes; use a high-pressure pump to pump the emulsified oil into the quenching The machine is rapidly cooled to 35°C; the cooled emulsified oil is homogenized in a kneader, the homogenization temperature is 35°C, and the homogenization time is 1 minute; the above-mentioned products from the kneader are packaged, and after packaging The p...

Embodiment 2

[0032] Raw materials were weighed according to the following formula (weight): 90 g of palm stearin, 10 g of seabuckthorn oil, 0.6 g of glyceryl monostearate, 800.6 g of Span, 0.005 g of butyl hydroxyanisole, and 0.07 g of potassium sorbate.

[0033] Preparation method of special oil for freezing: heating palm stearin to 80° C. for melting; cooling slightly after melting completely, adding seabuckthorn oil and butyl hydroxyanisole to 60° C., fully stirring and mixing the two; adding monostearic acid Glycerides, Span 80 and Potassium Sorbate are emulsified under heating, the emulsification speed is 900 rpm, the emulsification temperature is 65°C, and the emulsification time is 20 minutes; the uniformly emulsified oil is pumped into the quenching The machine is rapidly cooled to 30°C; the cooled emulsified oil is homogenized in a kneader, the homogenization temperature is 35°C, and the homogenization time is 2 minutes; the above-mentioned products from the kneader are packaged, a...

Embodiment 3

[0035] Raw materials were weighed according to the following formula (weight): palm stearin 85g, olive oil 15g, glyceryl monostearate 0.8g, span 800.8g, tocopherol 0.007g, citric acid 0.08g.

[0036] Preparation method of special grease for freezing: heating palm stearin to 70° C. for melting; cooling slightly after melting completely, adding olive oil and tocopherol to 65° C., fully stirring and mixing the two; adding glyceryl monostearate, Span 80 and citric acid are emulsified under heating, the emulsification speed is 1100 rpm, the emulsification temperature is 65°C, and the emulsification time is 30 minutes; use a high-pressure pump to pump the emulsified oil into the quenching machine for rapid cooling to 30°C; homogenize the cooled emulsified oil in a kneader, the homogenization temperature is 30°C, and the homogenization time is 3 minutes; the above-mentioned products coming out of the kneader are packaged, and the packaged products are sent into The ripening section c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com