Catalyst used for preparing furan from decarbonylation of furfural, and preparation method and application thereof

A technology for decarbonylation to produce furan and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unsatisfactory results, and achieve experimental results. Mild conditions, simple preparation method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

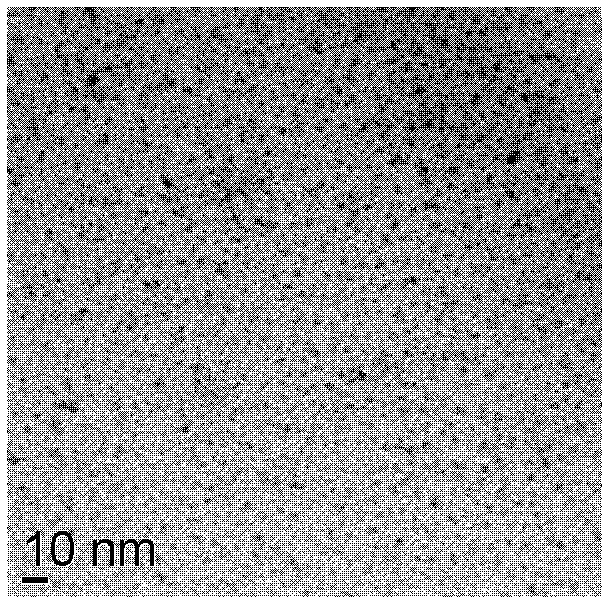

Image

Examples

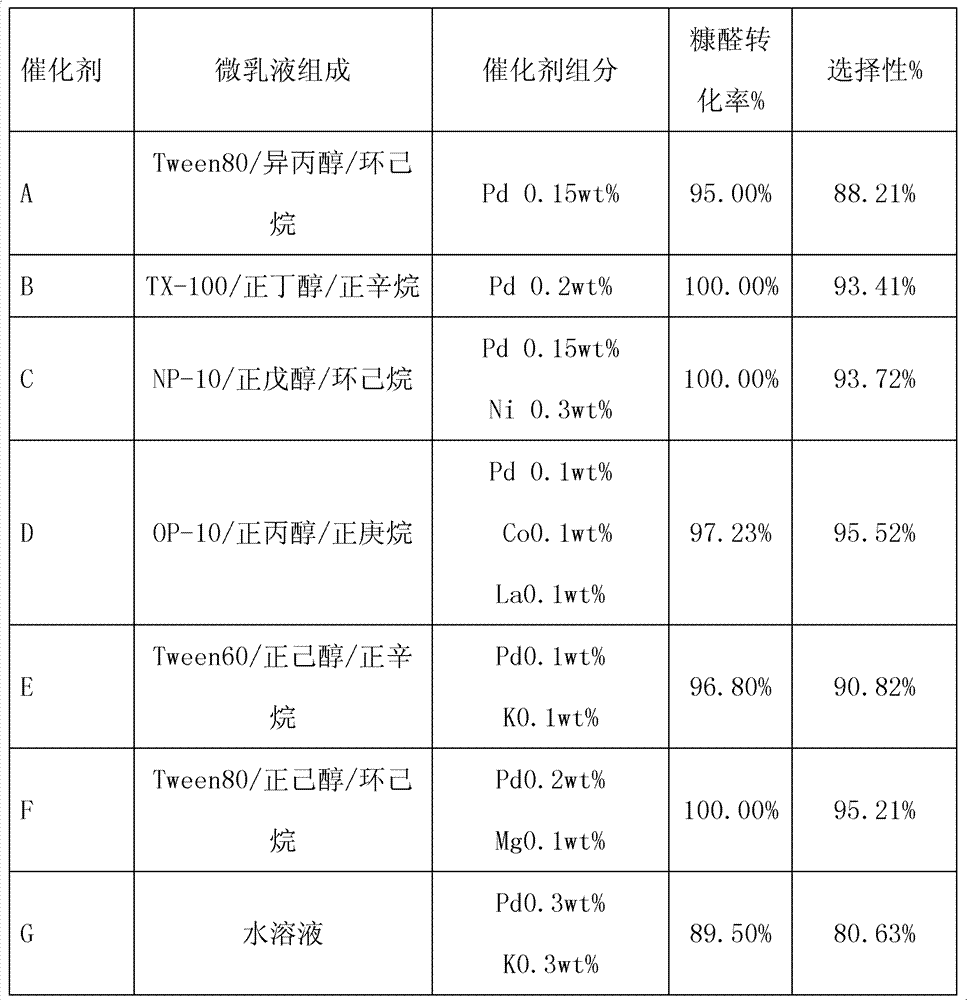

Embodiment 1

[0037] Weigh 100mgPd / ml of Pd(NO 3 ) 2 Solution 1.5ml, diluted to 5ml with deionized water, 13.8ml Tween80 and 17.73ml isopropanol were mixed with 20ml cyclohexane under magnetic stirring in a constant temperature water bath at 25°C, and then Pd(NO 3 ) 2 Solution, magnetically stirred for a certain period of time until a transparent microemulsion was obtained; a certain amount of hydrazine hydrate was added to the above microemulsion to make the Pd(NO in the microemulsion 3 ) 2 Reduced to elemental Pd; weigh 100g Al 2 o 3 Carrier, impregnating the reduced microemulsion onto the carrier. Then it was dried and calcined to prepare the catalyst A, wherein the Pd content was 0.15wt%.

Embodiment 2

[0039] Weigh 200mgPd / ml of PdCl 2 Solution 1.0ml, dilute to 5ml with deionized water, mix 14.2ml TX-100 and 18.23ml n-butanol with 25ml n-octane in a constant temperature water bath at 25°C, and then add the metal salt solution diluted with water , magnetic stirring for a certain period of time until a transparent microemulsion is obtained; a certain amount of hydrazine hydrate is added to the above microemulsion to make the PdCl in the microemulsion 2 Reduced to elemental Pd; weigh 100gTiO 2 Carrier, impregnating the reduced microemulsion onto the carrier. Then it was dried and calcined to prepare the catalyst B, wherein the Pd content was 0.2wt%.

Embodiment 3

[0041] Weigh 200mgPd / ml of Pd(NO 3 ) 2 Solution 1.5ml, 300mgNi / ml Ni(NO 3 ) 2 1.0ml of the solution was diluted to 5ml with deionized water. Mix 10ml NP-10 and 5ml n-pentanol with 30ml cyclohexane in a constant temperature water bath at 20°C under magnetic stirring, then add metal salt solution diluted with water, stir magnetically for a certain period of time until a transparent microemulsion is obtained, and add to the above microemulsion A certain amount of potassium borohydride is added to the emulsion to reduce the metal ions in the metal salt solution in the microemulsion to a simple state. Weigh 100gAl 2 o 3 Carrier, the reduced microemulsion is sprayed on the carrier, then dried and calcined to prepare the catalyst C. Wherein the Pd content is 0.15wt%. Wherein the Ni content is 0.3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com