Method for patching, overlay welding and reproducing large-scale hollow steel casting

A technology for steel castings and remanufacturing, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as large deformation, poor weld quality, and low strength, and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The following is a case analysis of railway wagon bolster and side frame steel castings as examples.

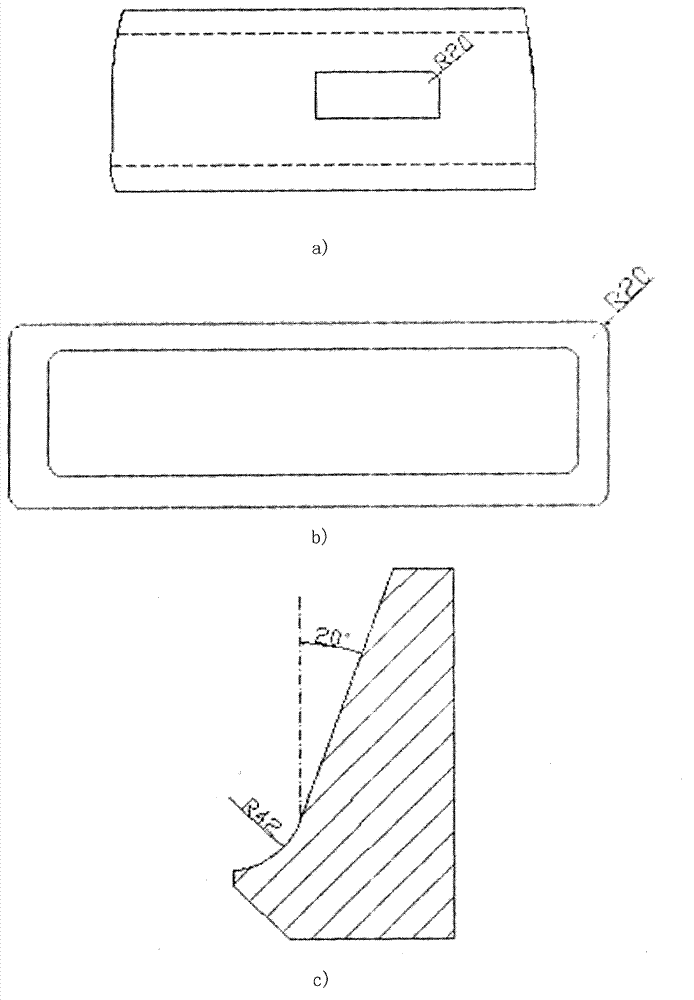

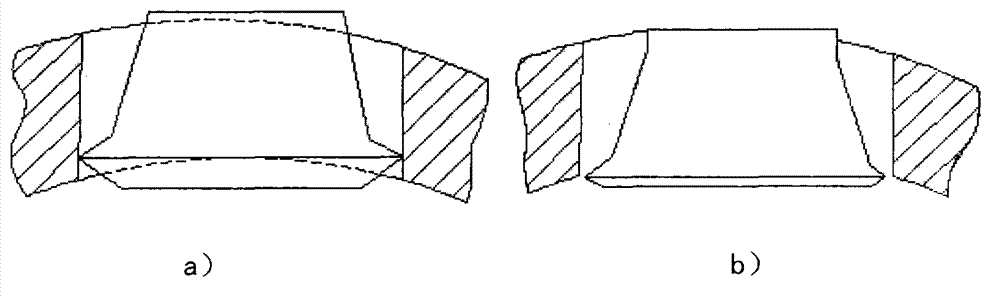

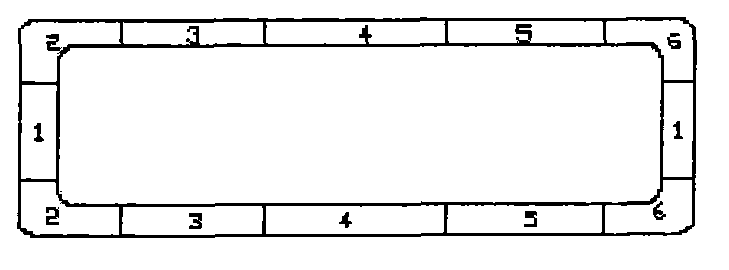

[0066] Because bolsters and side frames are important stress-bearing components in the running part of railway freight cars, their quality directly affects the development of railway transportation and the safety of life and property. Bolsters and side frames are cast from B+ grade (ZG25MnCrNi). During the welding repair of castings, due to the structural characteristics of the bolster and side frame and the high content of alloying elements, the hardening tendency is large, and cold and hot cracks are prone to occur. At the same time, the joint structure after welding is not uniform, especially in the overheated zone of the heat-affected zone. Coarse crystal grains can easily cause fracture. In view of these problems, from the welding method, the selection of welding materials, whether to open the bevel and the opening method of the bevel, the selection of voltage an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com