Deep-sea pressure-proof machinable buoyancy material and production method thereof

A kind of buoyancy material and deep-sea technology, applied in the field of solid buoyancy material for underwater submersibles, can solve the problems of high production cost, complicated manufacturing process, and complicated process, and achieve the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

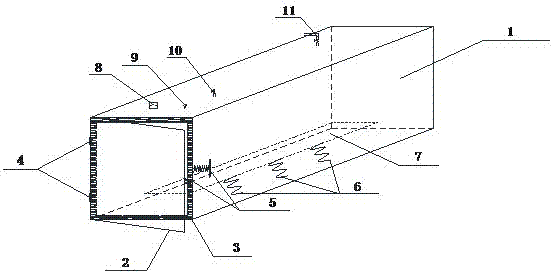

Image

Examples

Embodiment Construction

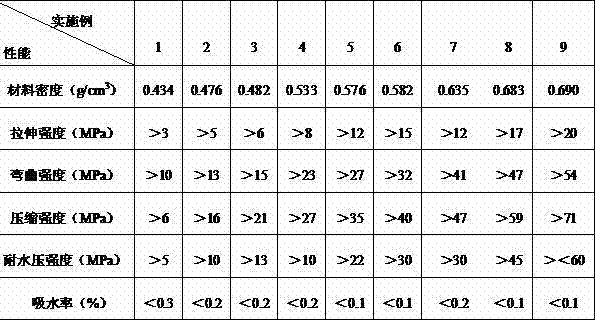

[0049] The buoyant material and its production method of the present invention will be further described in detail below in conjunction with specific examples.

[0050] Table 1 lists nine kinds of different formulations or techniques of the present invention, buoyancy material component ratios and techniques in parts by weight.

[0051] Table 1 Typical formula example formula table

[0052]

[0053] Note: The vinyl ester resin in the above table is a low-viscosity resin with a viscosity less than 1000cps at room temperature; the initiator is tert-butyl peroxybenzoate; the accelerator is cobalt naphthenate solution; the dispersant is BYK-906 dispersant; The agent is styrene; the coupling agent is KH-570 coupling agent; the "A" model hollow microspheres have a particle size of 10-100um, a compressive strength of 0.5MPa, and a bulk density of 0.02g / cm 3 Polymer hollow microspheres; "B" type hollow microspheres have a particle size of 30-150um, a compressive strength of 1.7M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com