Preparation method of nano Co3O4 octahedron powder

An octahedral and powder technology, which is applied in the field of preparation of Co3O4 octahedral powder and achieves the effects of good controllability, good operability and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In this embodiment, a kind of nano Co 3 o 4 The preparation method of octahedral powder comprises the steps:

[0017] Step 1: Prepare a solution with 0.15g of cobalt nitrate and 30mL of absolute ethanol, and call it solution A;

[0018] Step 2: Add 0.10 g of PVP to the solution A prepared in step 1 to obtain a mixed solution, then magnetically stir the above mixed solution for 10 minutes, and record it as solution B;

[0019] Step 3: Add the solution B prepared in step 2 into a reaction kettle with a capacity of 50mL, and heat it to 180°C for 36h to obtain a solution containing Co 3 o 4 Precipitated solid-liquid mixture;

[0020] Step 4: the Co obtained in step 3 3 o 4 The precipitated solid-liquid mixture was centrifuged and washed five times with deionized water and absolute ethanol, respectively, and then the centrifuged and washed product was dried at 60 °C for 6 h to obtain nano-Co 3 o 4 Octahedral powder.

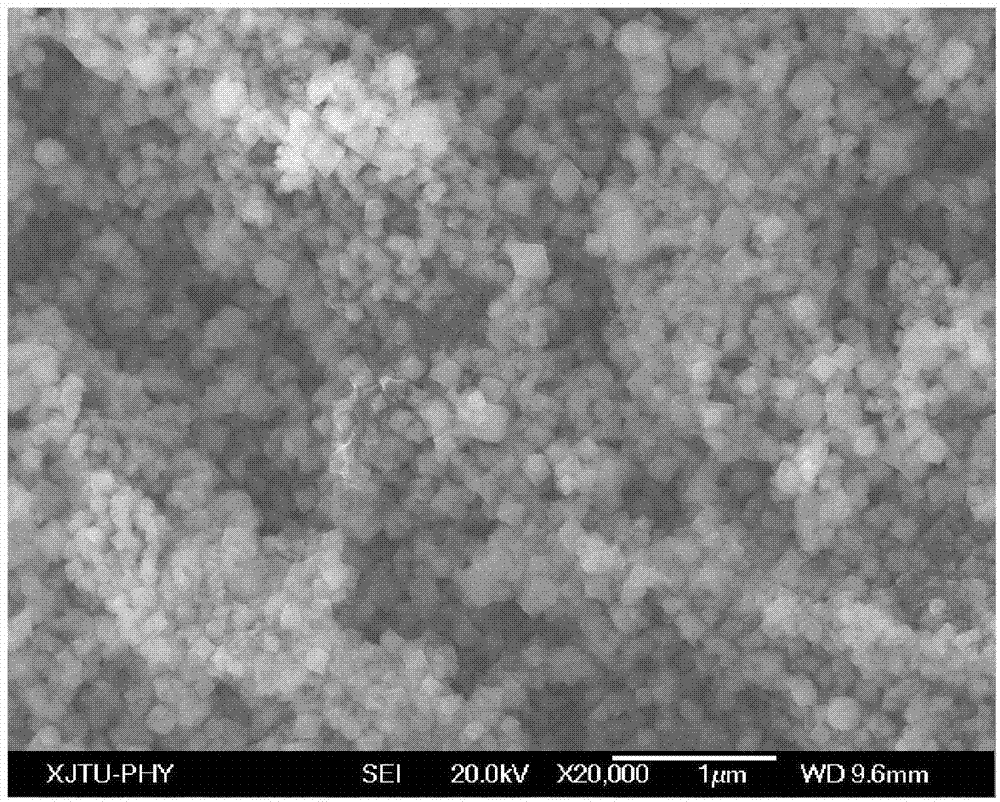

[0021] Such as figure 1 As shown, the nano-Co p...

Embodiment 2

[0023] In this embodiment, a kind of nano Co 3 o 4 The preparation method of octahedral powder comprises the steps:

[0024] Step 1: Prepare a solution with 0.15g of cobalt nitrate and 30mL of absolute ethanol, and call it solution A;

[0025] Step 2: Add 0.05g of PVP to the solution A prepared in step 1 to obtain a mixed solution, then magnetically stir the above mixed solution for 10 minutes, and record it as solution B;

[0026] Step 3: Add the solution B prepared in step 2 into a reaction kettle with a capacity of 50mL, and heat it to 180°C for 36h to obtain a solution containing Co 3 o 4 Precipitated solid-liquid mixture;

[0027] Step 4: the Co obtained in step 3 3 o 4 The precipitated solid-liquid mixture was centrifuged and washed five times with deionized water and absolute ethanol, respectively, and then the centrifuged and washed product was dried at 60 °C for 6 h to obtain nano-Co 3 o 4 Octahedral powder.

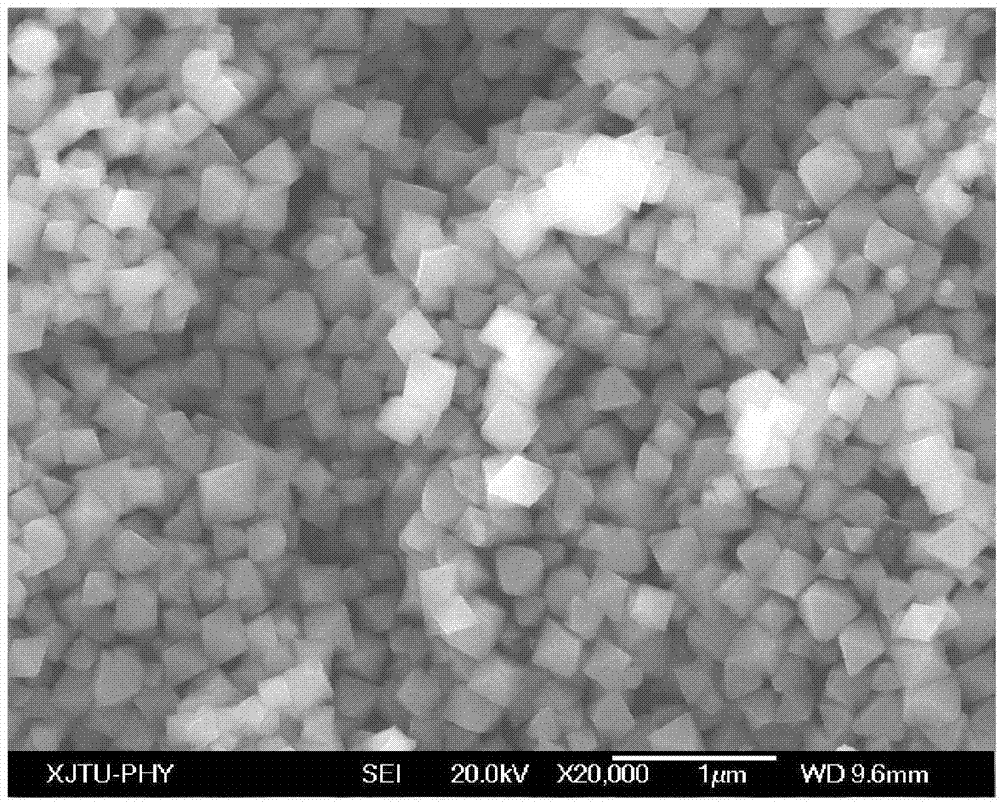

[0028] Such as figure 2 As shown, the nano-Co p...

Embodiment 3

[0030] In this embodiment, a kind of nano Co 3 o 4 The preparation method of octahedral powder comprises the steps:

[0031] Step 1: Mix 0.15g of cobalt nitrate and 35mL of absolute ethanol into a solution, which is called solution A;

[0032] Step 2: Add 0.15g of PVP to the solution A prepared in step 1 to obtain a mixed solution, then magnetically stir the above mixed solution for 5 minutes, and record it as solution B;

[0033] Step 3: Add the solution B prepared in step 2 into a reaction kettle with a capacity of 50mL, and heat it to 140°C for 48h to obtain a solution containing Co 3 o 4 Precipitated solid-liquid mixture;

[0034] Step 4: the Co obtained in step 3 3 o 4 The precipitated solid-liquid mixture was centrifuged and washed three times with deionized water and absolute ethanol, respectively, and then the centrifuged and washed product was dried at 80 °C for 4 h to obtain nano-Co 3 o 4 Octahedral powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com