Production method for improving hand touch and dispersing technological parameter of elastic paint and stirring device applying production method

A technology of process parameters and production methods, applied in the field of elastic paint production and processing technology, can solve the problems of unfavorable production promotion and application, affecting yield, low cost performance, etc., to improve market value and application prospects, avoid excessive dispersion phenomenon, The effect of optimizing the dispersion process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] step 1:

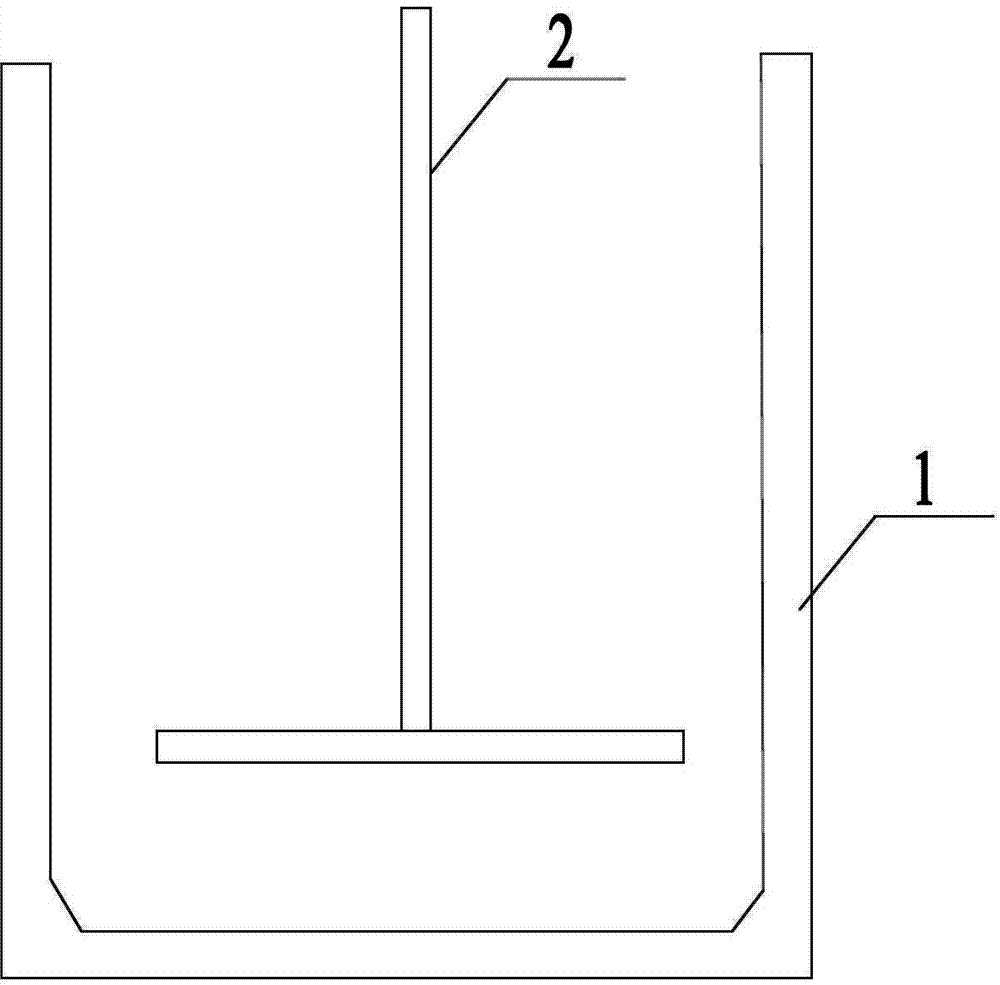

[0023] Put polyester resin, aromatic hydrocarbon solvent and leveling agent into the mixing tank 1, and use the three-bladed paddle 2 for high-speed stirring process, keep the stirring speed of the three-bladed paddle 2 at 1000-1500, and the stirring time is 5-10 minutes .

[0024] Step 2:

[0025] The initial speed stirring process is carried out by the three-blade paddle 2, and the stirring speed of the three-blade paddle 2 is kept at 300-700rpm, and the dummy powder is added in the mixing tank 1, and the initial speed stirring process is stopped after the dummy powder is added.

[0026] Step 3:

[0027] Increase the stirring speed of the three-blade paddle 2 to 1500rpm, enter the medium-speed stirring process, and stir for no more than 40 minutes to fully disperse the dull powder.

[0028] After the above steps are completed, the fineness value of the raw material in the mixing tank 1 is 4H, the viscosity value is 2300cps / 23°C, and the gloss value is 1.5...

Embodiment 2

[0030] step 1:

[0031] Put polyester resin, aromatic hydrocarbon solvent and leveling agent into the mixing tank 1, and use the three-bladed paddle 2 for high-speed stirring process, keep the stirring speed of the three-bladed paddle 2 at 1000-1500, and the stirring time is 5-10 minutes .

[0032] Step 2:

[0033] The initial speed stirring process is carried out by the three-blade paddle 2, and the stirring speed of the three-blade paddle 2 is kept at 300-700rpm, and the dummy powder is added in the mixing tank 1, and the initial speed stirring process is stopped after the dummy powder is added.

[0034] Step 3:

[0035] Increase the stirring speed of the three-blade paddle 2 to 1400rpm, and enter the medium-speed stirring process, and the stirring time is 60 minutes, so that the dull powder is fully dispersed.

[0036] After the above steps are completed, the fineness value of the raw material in the mixing tank 1 is 4H, the viscosity value is 2200cps / 23°C, and the gloss...

Embodiment 3

[0038] step 1:

[0039] Put polyester resin, aromatic hydrocarbon solvent and leveling agent into the mixing tank 1, and use the three-bladed paddle 2 for high-speed stirring process, keep the stirring speed of the three-bladed paddle 2 at 1000-1500, and the stirring time is 5-10 minutes .

[0040] Step 2:

[0041] The initial speed stirring process is carried out by the three-blade paddle 2, and the stirring speed of the three-blade paddle 2 is kept at 300-700rpm, and the dummy powder is added in the mixing tank 1, and the initial speed stirring process is stopped after the dummy powder is added.

[0042] Step 3:

[0043] Increase the stirring speed of the three-blade paddle 2 to 1500rpm, enter the middle-speed stirring process, and stir for 60 minutes to fully disperse the dull powder.

[0044] After the above steps are completed, the fineness value of the raw material in the mixing tank 1 is 4H, the viscosity value is 2100cps / 23°C, and the gloss value is 1.4~1.5degree. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com