Aluminum alloy sacrificial anode material for storage tank coil and preparation method thereof

A sacrificial anode and aluminum alloy technology, which is applied in the field of aluminum alloy sacrificial anode materials for storage tank coils and their preparation, can solve the problems of large capacitance, easy passivation, failure, etc., and achieves fine grains and difficult passivation. , The effect of dense and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

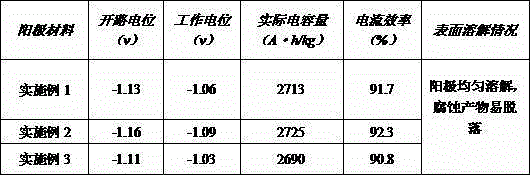

Embodiment 1

[0024] The weight percentage composition of the aluminum alloy sacrificial anode material for storage tank coils in this embodiment is: Zn: 5.5%; In: 0.02%; Mg: 1.5%; Ti: 0.05%; B: 0.03%, and the balance is aluminum, Impurity content ≤ 0.1%.

[0025] According to the recipe, weigh various alloying elements and wrap them tightly with aluminum foil. The temperature is set at 760°C, and the aluminum ingot is heated together with the furnace until it is completely melted. According to the melting point of each alloy element, it is pressed into the molten aluminum water at different temperatures. After several times of stirring, it is left in the furnace for 10 minutes. Then stir gently to mix evenly, cast in cast iron molds, and let it cool and solidify naturally.

Embodiment 2

[0027] The weight percentage composition of the aluminum alloy sacrificial anode material for storage tank coils in this embodiment is: Zn: 3.5%; In: 0.03%; Mg: 1.0%; Ti: 0.05%; B: 0.015%, and the balance is aluminum, Impurity content ≤ 0.1%.

[0028] According to the recipe, weigh various alloying elements and wrap them tightly with aluminum foil. The temperature is set at 760°C, and the aluminum ingot is heated together with the furnace until it is completely melted. According to the melting point of each alloy element, it is pressed into the molten aluminum water at different temperatures. After several times of stirring, it is left in the furnace for 10 minutes. Then stir gently to mix evenly, cast in cast iron molds, and let it cool and solidify naturally.

Embodiment 3

[0030] The weight percentage formula of the aluminum alloy sacrificial anode material for storage tank coils in this embodiment is: Zn: 5.0%; In: 0.03%; Mg: 1.5%; Ti: 0.05%; B: 0.05%, the balance is aluminum, Impurity content ≤ 0.1%.

[0031] According to the alloy formula, weigh various alloy elements and wrap them tightly with aluminum foil. The temperature is set at 760°C, and the aluminum ingot is heated together with the furnace until it is completely melted. According to the melting point of each alloy element, it is pressed into the molten aluminum water at different temperatures. After several times of stirring, it is left in the furnace for 10 minutes. Then stir gently to mix evenly, cast in cast iron molds, and let it cool and solidify naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com