Intelligent excavation broken-type loader

A crushing and loader technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve problems such as low construction efficiency, large safety hazards, and large changes in geological structure, etc. Achieve the effect of improving safety, improving work efficiency and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

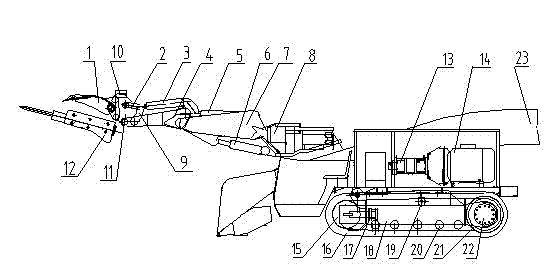

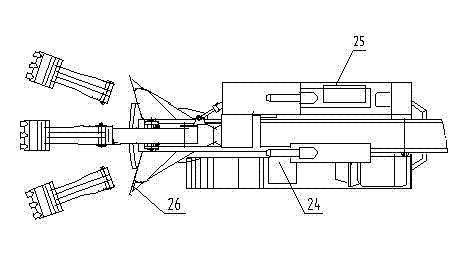

[0015] in figure 1 with figure 2 Among them, the backhoe loader includes a transportation mechanism 23, a traveling mechanism, a hydraulic system 13, an electrical system 14, an EPEC intelligent remote control system 24, a monitoring communication system 25 and a working mechanism. The hydraulic system includes a hydraulic motor, a manual reversing valve, and a manual pilot. Valves, variable plunger pumps, couplings, radiators, and oil tanks. The hydraulic system is equipped with ten hydraulic control multi-way reversing valves; the working mechanism includes bucket 1, chain frame I2, bucket cylinder 3 , Forearm 4, Forearm cylinder 5, Boom cylinder 6, Boom 7, Boom seat 8, Chain frame Ⅱ 9, Spray device 10, Quick connector 11, Breaker 12, the bucket or breaker is connected to the quick The connector 11 is connected, the quick connector is connected with the chain frame I and the forearm, the chain frame I and the chain frame II are connected with the forearm and the bucket cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com