Magnetoelectric composite structure and fabrication method thereof

A manufacturing method and magnetoelectric composite technology, which are applied in the manufacture/assembly of magnetostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, etc., can solve the problem of poor stress conduction and signal-to-noise ratio. Unsatisfactory, poor flat uniformity, etc., to achieve good bonding, common mode noise suppression, and prevention of short-circuit leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

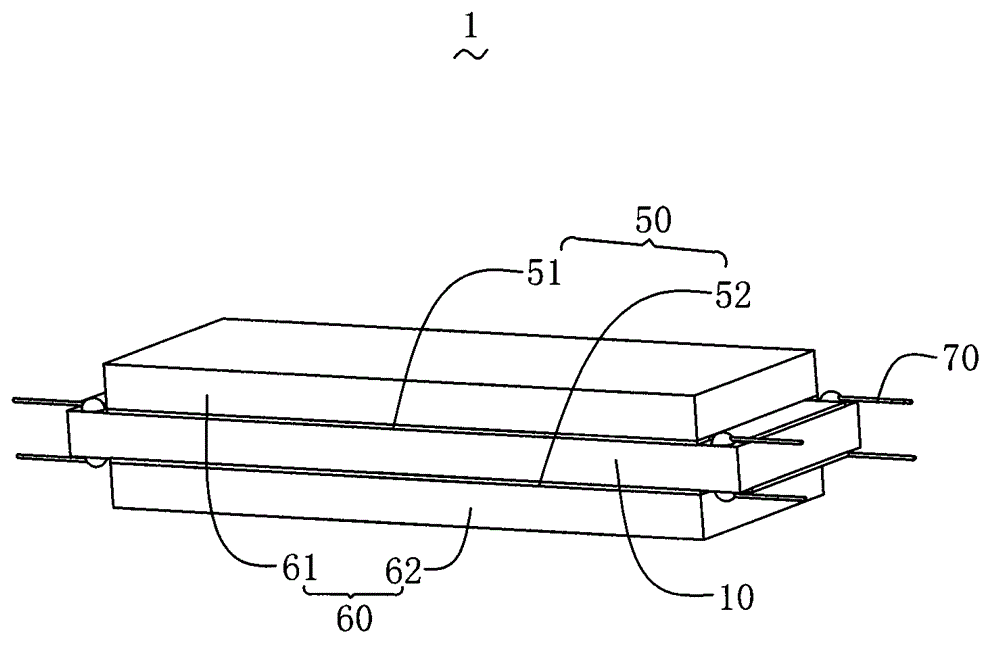

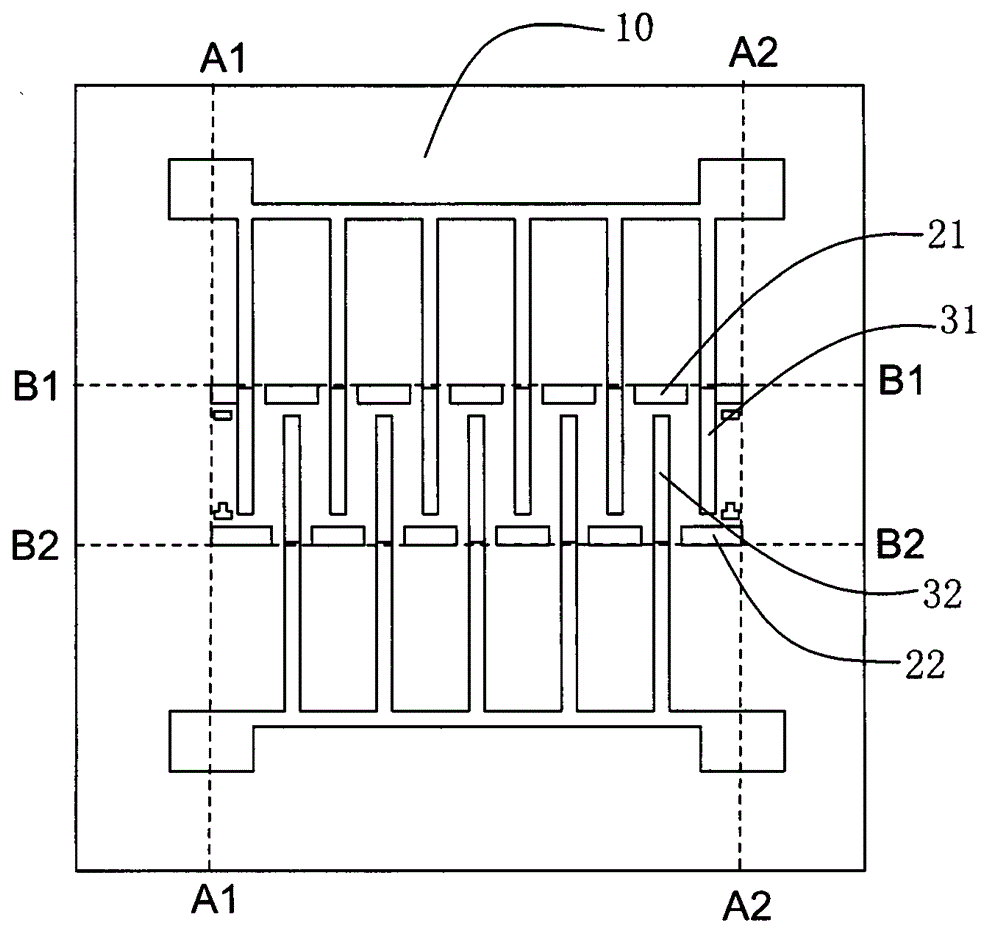

[0044] like figure 1 Shown is the magnetoelectric composite structure 1 of the present invention, which includes a piezoelectric ceramic sheet 10, a silver electrode placed on the piezoelectric ceramic sheet 10, a magnetostrictive material layer 60, and a piezoelectric ceramic sheet 10 and a magnetostrictive The stretchable material layer 60 is used to isolate the piezoelectric ceramic sheet 10 from the ink layer 50 of the magnetostrictive material layer 60 . Wherein, the silver electrodes include a first silver electrode located above the piezoelectric ceramic sheet 10 and a second silver electrode located below the piezoelectric ceramic sheet 10, and the ink layer 50 includes a first ink layer located above the first silver electrode. 51 and the second ink layer 52 below the second silver electrode, the magnetostrictive material layer 60 includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com