Manufacturing method and used etching method of complementary metal-oxide-semiconductor transistor (CMOS) imaging sensor

A technology of an image sensor and a manufacturing method, applied in radiation control devices and other directions, can solve the problems of lack of ideal and obvious notching, and achieve the effects of simple implementation, avoiding notching phenomenon, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

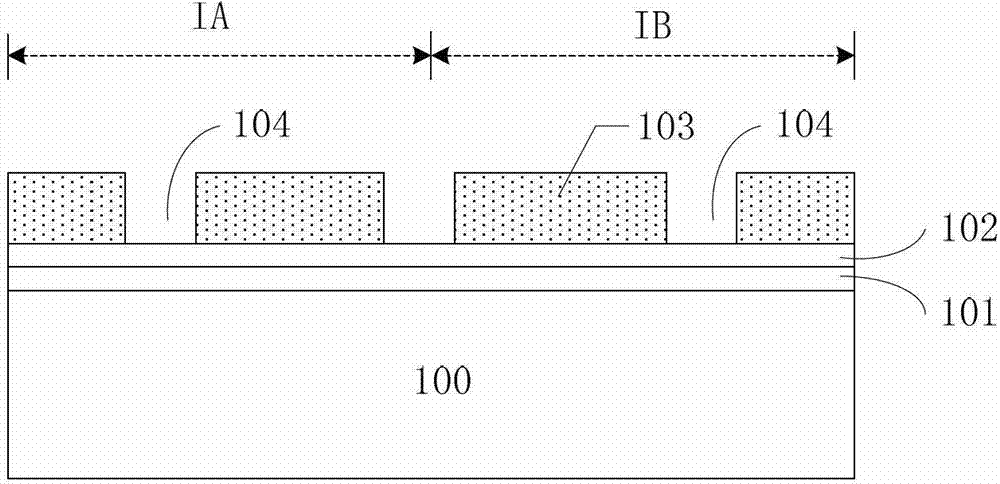

[0028] It should be noted that the embodiments of the present invention can be applied not only to the TSV etching process, but also to other etching processes for manufacturing CMOS image sensors.

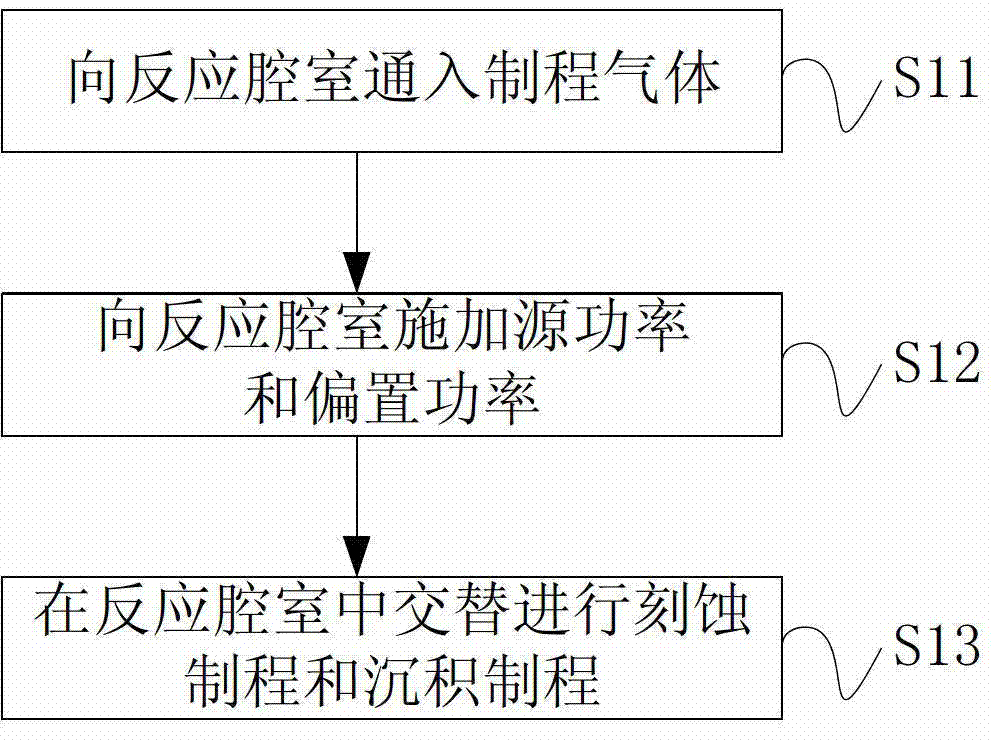

[0029] Such as image 3 As shown, the etching method for manufacturing a CMOS image sensor provided by the first embodiment of the present invention includes the following steps:

[0030] S11. Introducing a process gas into the reaction chamber, where the process gas includes an etching gas and a sidewall protection gas.

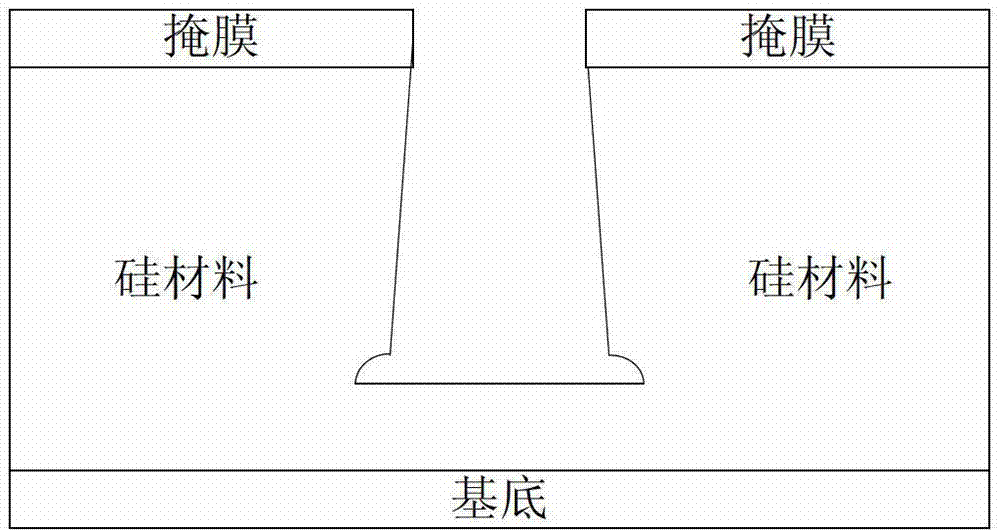

[0031] Specifically, a workpiece to be processed is placed in the reaction chamber, which is a semiconductor substrate with a pattern of shallow trenches defined therein, for manufacturing a CMOS image sensor. Etching gas including SF 6 and other gases that can cause etching reactions, sidewall protection gases inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com