Cu2ZnSnS4/a-Si heterojunction solar cell and manufacturing method thereof

A technology of solar cells and heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as battery environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

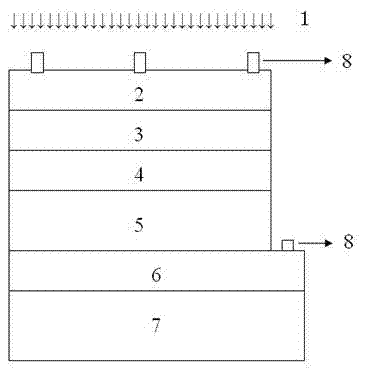

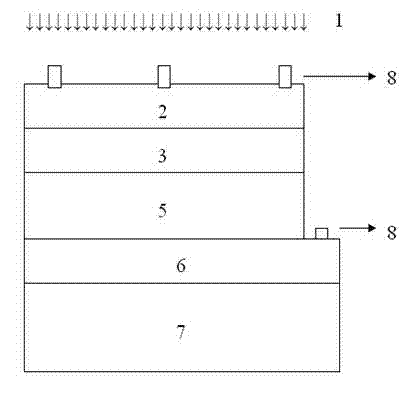

[0022] The above Cu-based 2 ZnSnS 4 Novel Cu for Heterojunction Solar Cells 2 ZnSnS 4 A method for preparing an α-Si heterojunction solar cell, characterized in that it comprises the following preparation steps:

[0023] Step 1. The substrate is cleaned, and the substrate in the tool is selected from FTO glass or metal sheet or metal-coated glass substrate;

[0024] Step 2, preparation of CZTS thin film: using magnetron sputtering metal multilayer film preset layer subsequent vulcanization method to prepare p-type CZTS thin film,

[0025] This step can adopt existing technology, concrete steps are as follows:

[0026] (2-1) First, the magnetron sputtering method is used to sputter Zn, Sn and Cu films on the substrate in turn (the sequence can be adjusted), wherein the purity of each metal target is higher than 99.999%; wherein each layer of metal Thin film sputtering parameters: the background vacuum is 5*10 -2 pa-5*10 -4 pa, the Ar flow rate is 5sccm-100sccm, the sputt...

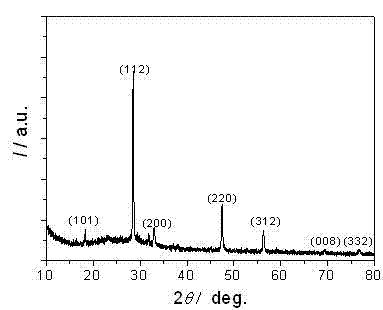

specific example 1

[0033] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention should not be limited thereby.

[0034] A new type of Cu 2 ZnSnS 4 A thin-film solar cell and a preparation method thereof, comprising the steps of:

[0035] (1) Clean the ordinary FTO glass substrate, the specific process is as follows:

[0036] Organic solvent ultrasonic cleaning → acetone ultrasonic cleaning → alcohol ultrasonic cleaning → ultrapure water ultrasonic cleaning

[0037] (2) Sputtering Zn, Sn and Cu films respectively in sequence on the above-mentioned cleaned FTO substrate. The corresponding metal thin film sputtering parameters of each layer are as follows:

[0038] Zn film sputtering parameters: the background vacuum is 5*10 -4 pa, the Ar flow rate is 20sccm, the sputtering pressure is kept constant at 0.1pa, the sputtering power is 20W, and the sputtering thickness is 60nm.

[0039] Sn film sputtering paramet...

specific example 2

[0050] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention should not be limited thereby.

[0051] A new type of Cu 2 ZnSnS 4 A thin-film solar cell and a preparation method thereof, comprising the steps of:

[0052] (1) Clean the ordinary FTO glass substrate, the specific process is as follows:

[0053] Organic solvent ultrasonic cleaning → acetone ultrasonic cleaning → alcohol ultrasonic cleaning → ultrapure water ultrasonic cleaning

[0054] (2) Sn, Zn and Cu films were respectively sputtered successively on the above-mentioned cleaned FTO substrate. The corresponding metal thin film sputtering parameters of each layer are as follows:

[0055] Sn film sputtering parameters: the background vacuum is 5*10 -4 pa, the Ar flow rate is 20 sccm, the sputtering pressure is kept constant at 0.1 Pa, the sputtering power is 30 W, the sputtering film thickness is 140 nm, and the substrate tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com