Low voltage ride through control method for full-power high-speed permanent synchronous fan

A low-voltage ride-through, permanent magnet synchronous technology, applied in wind power generation, single-grid parallel feeding arrangement, greenhouse gas reduction, etc., can solve the problem of not considering the optimal control of the DC side crowbar, and achieve the effect of reducing the load of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

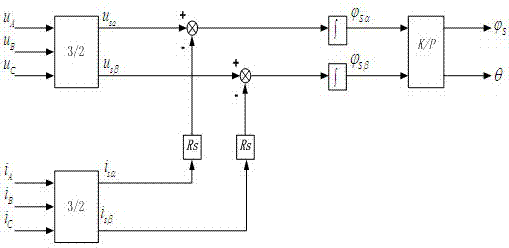

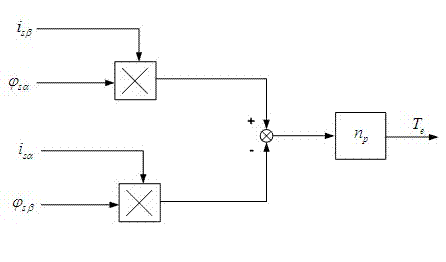

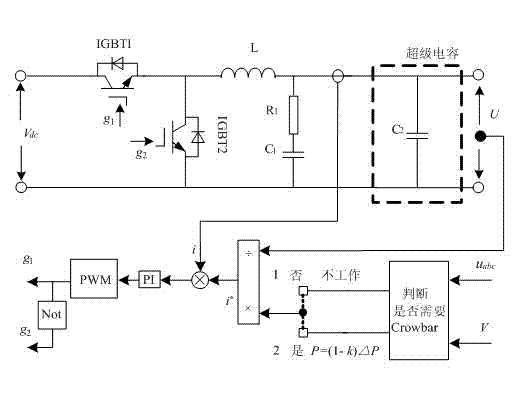

[0014] The low-voltage ride-through control method of the full-power high-speed permanent magnet synchronous fan involves two main parts: the first part is the direct torque control method of the inverter on the motor side (see figure 1 ), the second part is the crowbar circuit control method with energy storage link on the DC side (see image 3 ). in:

[0015] The first part is the direct torque control method of the inverter on the motor side.

[0016] The direct torque control is performed on a two-phase stationary coordinate system (αβ coordinate). The motor matrix equation in the αβ coordinate system is:

[0017]

[0018] In the formula,

[0019] u sa , u sβ , u ra , u rβ are the components of the stator / rotor voltage on the αβ coordinate system;

[0020] i sa i sβ i ra i rβ are the components of the stator / rotor current on the αβ coordinate system;

[0021] R s , R r , L s , L m , L r , p, ω are stator / rotor winding equivalent resistance, stator in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com