Method for warming after-treatment burner system

A burner and combustion energy technology, which is applied to the electronic control, exhaust treatment, charging system, etc. of the exhaust gas treatment device, can solve the problems of inactivation, etc., achieve low cost, reduce power consumption, and avoid excessive energization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

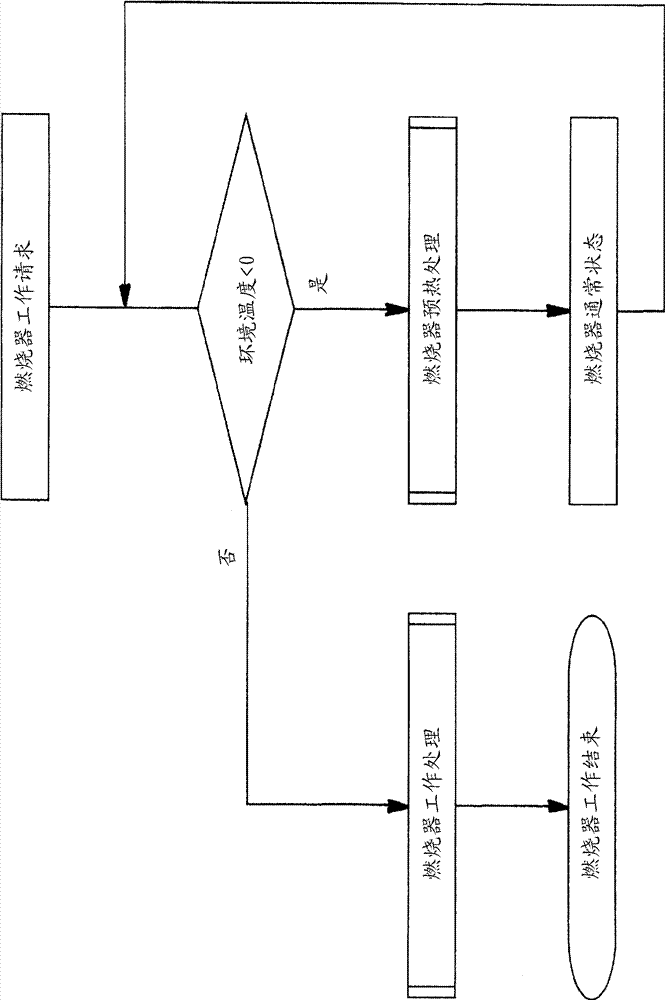

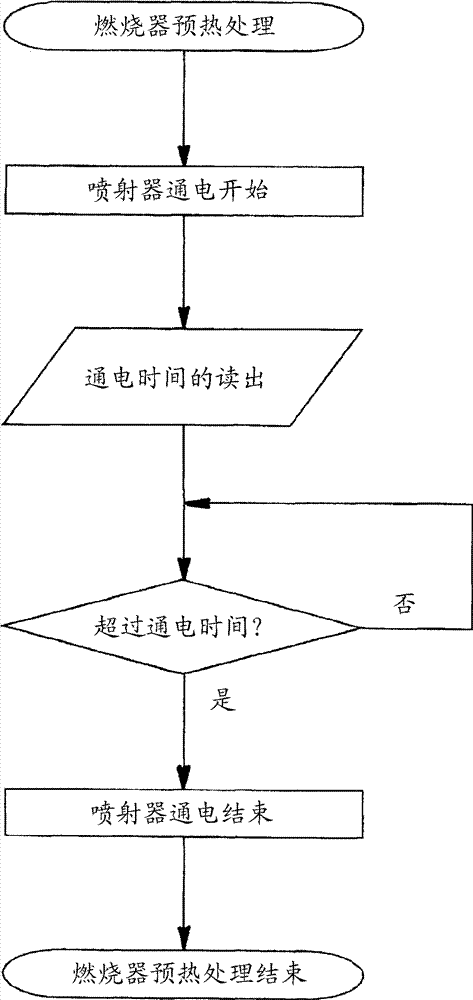

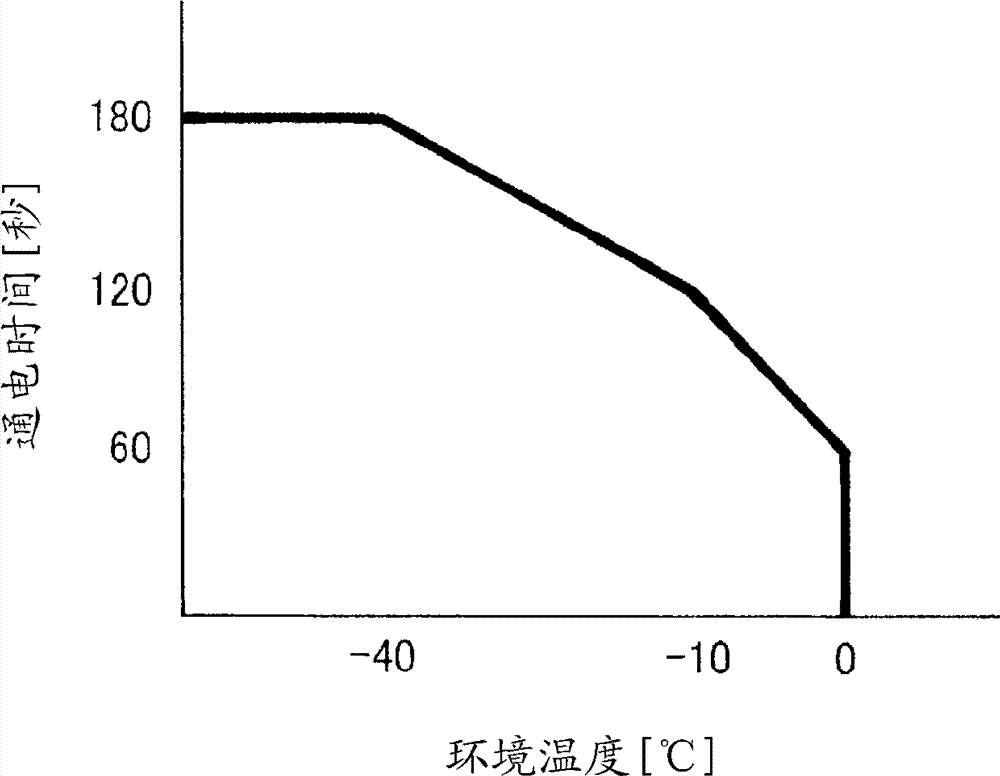

[0032] Below, refer to the attached Figure one The embodiments of the present invention will be described.

[0033] Figure 1 ~ Figure 5 Is a diagram showing the basic structure of an aftertreatment burner system to which the present invention is applied, figure 1 The reference numeral 1 in the figure represents a diesel engine equipped with a turbocharger 2, and the intake air 4 guided from the air cleaner 3 is sent to the compression of the turbocharger 2 through the intake pipe 5 The engine 2a sends the intake air 4 pressurized by the compressor 2a to an intercooler (intercooler) 6 for cooling, and then guides the intake air 4 from the intercooler 6 to an intake manifold (manifold) 7, and distributes Give each cylinder 8 of diesel engine 1 (in figure 1 Exemplified in the case of 6 cylinders in series), in addition, the exhaust gas 9 discharged from each cylinder 8 of the diesel engine 1 is sent to the turbine 2b of the turbocharger 2 via the exhaust manifold 10, and is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com