Hybrid electric vehicle using super-capacitor accessory power system

A technology of hybrid electric vehicles and super capacitors, which is applied to the arrangement of multiple different prime movers and power units of electric vehicles and general power units, to achieve the effects of improving energy utilization efficiency and service life, reducing fuel consumption and reliable starting current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

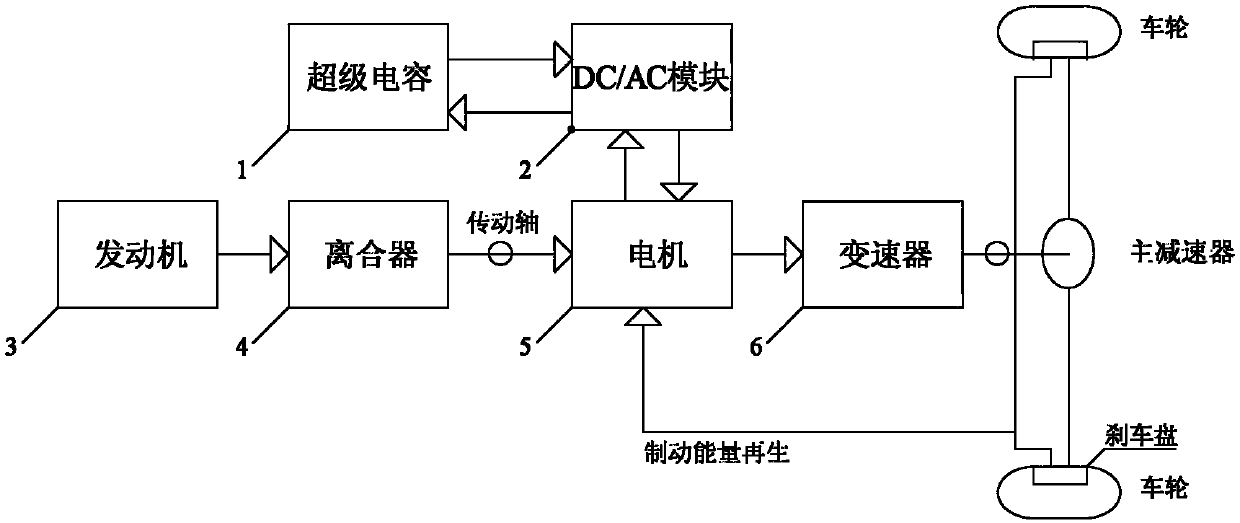

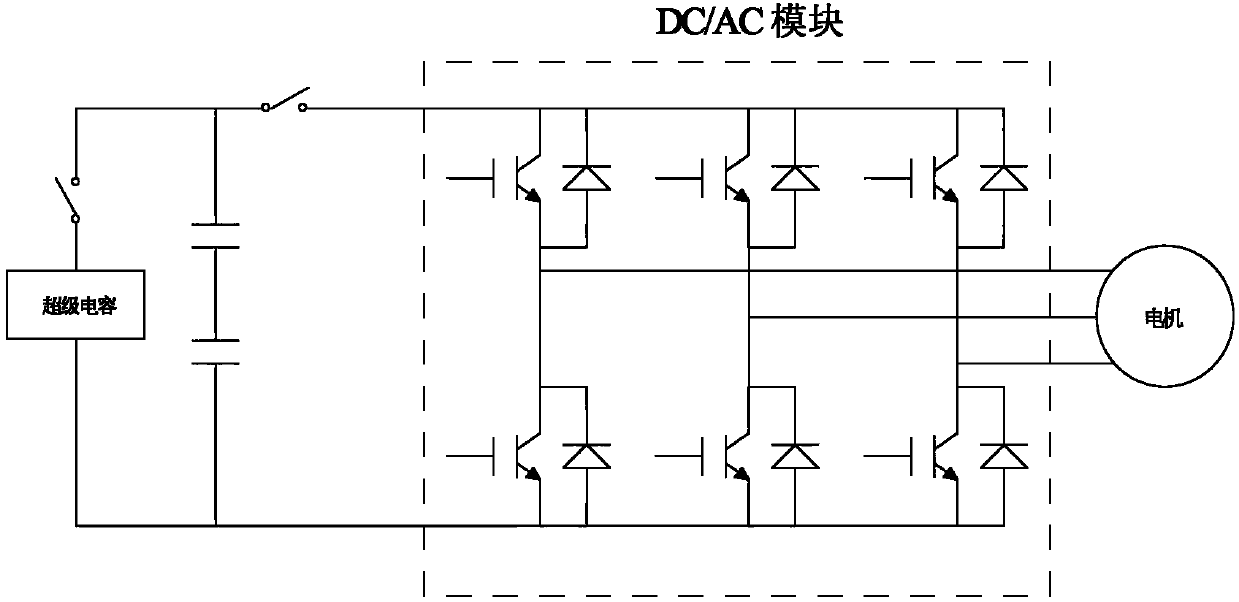

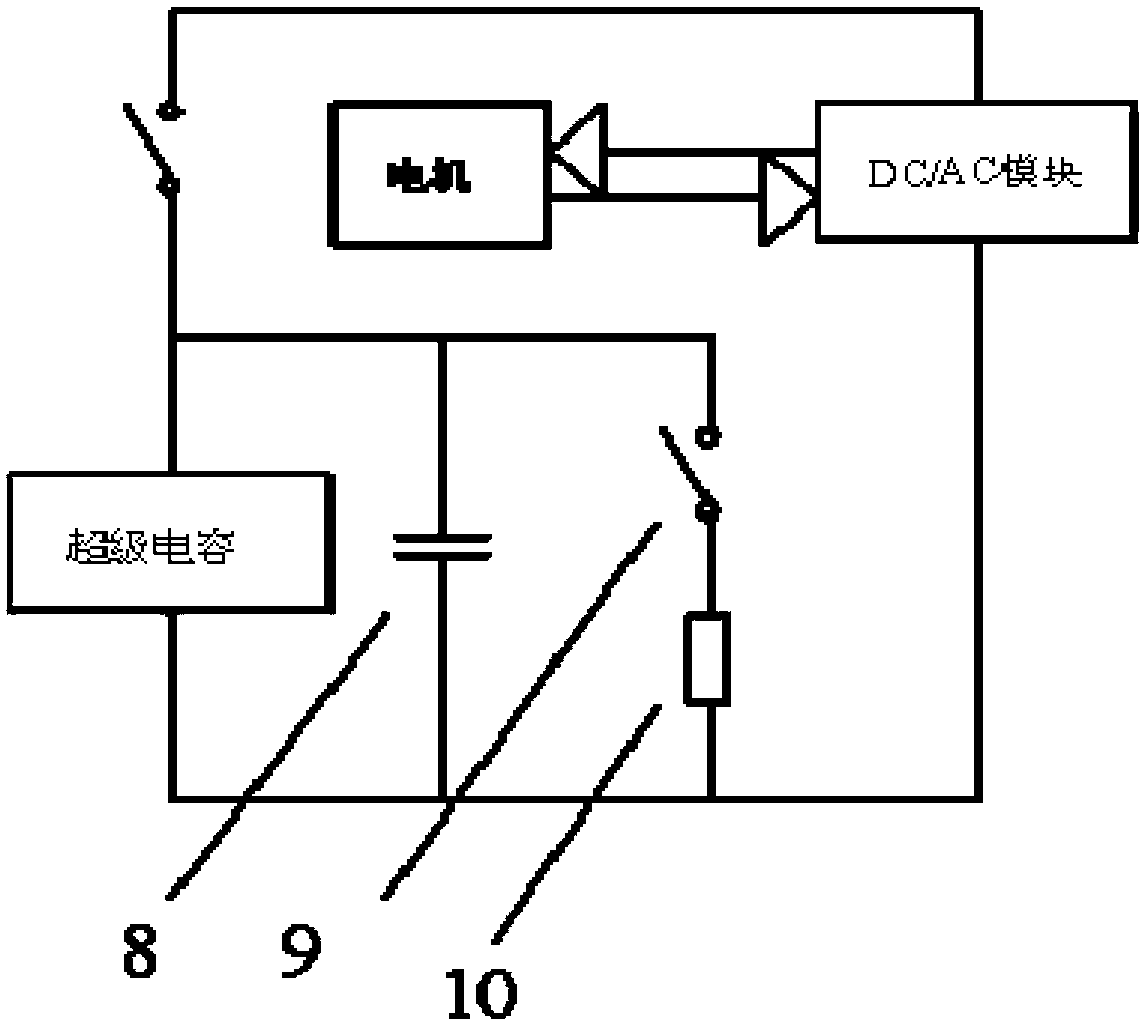

[0023] Such as figure 1 As shown, the application structure of the supercapacitor power supply system of the present invention on a hybrid electric vehicle includes: a supercapacitor 1, a DC / AC module 2, an engine 3, a clutch 4, a motor 5, and a transmission 6. Among them, supercapacitor 1 consists of 150 supercapacitor monomers (such as 2.7V and 3000F supercapacitor monomers produced by Maxwell in the United States) in series, and the specifications of the module are 405V and 20F. The circuit diagram of DC / AC module 2 is attached figure 2 shown. Engine 3 adopts gasoline internal combustion engine, also can use internal combustion engines such as diesel engine. The motor 5 is a switched reluctance motor (such as a switched reluctance motor with a model number of DT336D31S produced by Beijing Zhongfang Ruili Electromechanical Co., Ltd.).

[0024] The connection relationship is as follows: the supercapacitor 1 is connected to the DC / AC module 2, the DC / AC module 2 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com