Tackifier and preparation method thereof

A technology of adhesives and water-retaining agents, which is applied in the field of adhesives and their preparation, can solve the problems of limited use, limited application range of adhesives, etc., and achieve a wide range of applications, outstanding anti-sag performance, and outstanding anti-slip ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

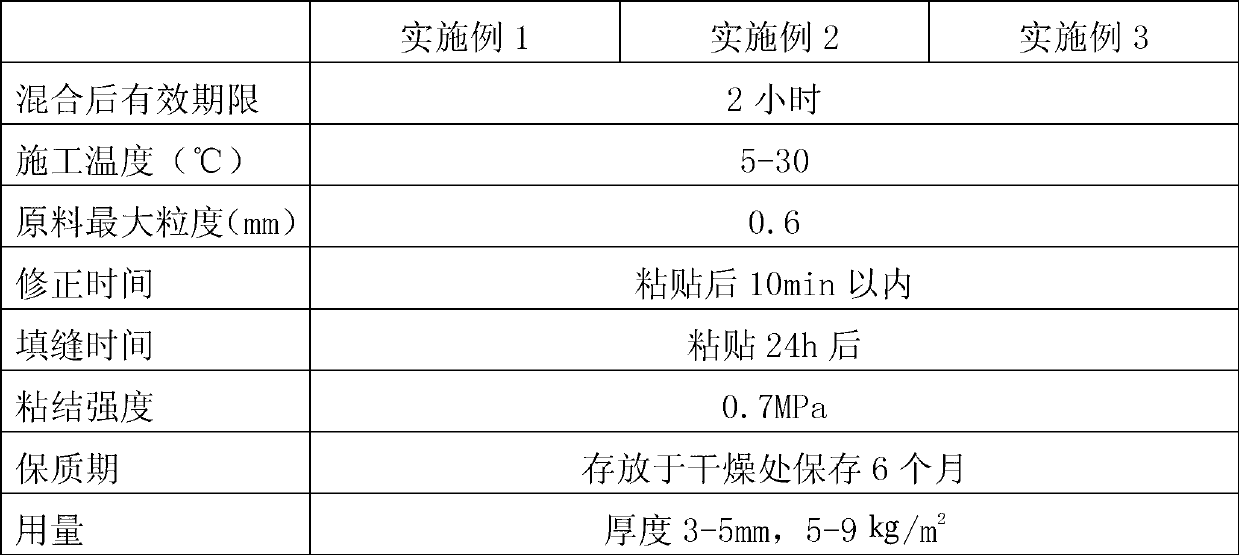

Examples

Embodiment 1

[0021] An adhesive, which is made of the following raw materials by weight: cement: 430 parts, quartz sand: 550 parts, latex powder: 21 parts, water-retaining agent: 0.5 parts, wood fiber: 4 parts, calcium formate 25 parts, pp fiber : 1 part; In the present embodiment, what described cement used was 425 cement, and what the water-retaining agent used was polyacrylamide-polyacrylamide.

[0022] The amount of raw materials used in the production of 2000kg adhesive is: 425 cement: 833.7Kg, quartz sand: 1066.4Kg, latex powder: 40.8Kg, polyacrylamide-polyacrylamide: 1.1Kg, wood fiber: 7.6Kg, calcium formate 48.5Kg, pp fiber: 1.9Kg.

[0023] The preparation method is as follows: first pour 425 cement into the production equipment and stir for 7 minutes, and then add quartz sand, latex powder, acrylamide-polyacrylamide, wood fiber, calcium formate and pp fiber in proportion under the condition of stirring Stir in the production equipment at the same time, and pack it into bags after...

Embodiment 2

[0025] An adhesive, which is made of the following raw materials in parts by weight: cement: 470 parts, quartz sand: 430 parts, latex powder: 27 parts, water-retaining agent: 3 parts, wood fiber: 2 parts, calcium formate 18 parts, pp fiber : 3 parts; In the present embodiment, what described cement used was 425 cement, and what water retaining agent used was sodium polyacrylate-sodium polyacrylate.

[0026] The amount of each raw material used in the production of 2000kg adhesive is: 425 cement: 986.4Kg, quartz sand: 902.4Kg, latex powder: 56.6Kg, polyacrylamide-polyacrylamide: 6.3Kg, wood fiber: 4.2Kg, calcium formate 37.8Kg, pp fiber: 6.3Kg.

[0027] The preparation method is as follows: first pour 425 cement into the production equipment and stir for 5 minutes, and then mix quartz sand, latex powder, polyacrylamide-polyacrylamide, wood fiber, calcium formate and pp fiber under the condition of stirring Add it into the production equipment and stir at the same time. After t...

Embodiment 3

[0029] An adhesive, which is made of the following raw materials in parts by weight: cement: 450 parts, quartz sand: 500 parts, latex powder: 25 parts, water-retaining agent: 2 parts, wood fiber: 3 parts, calcium formate: 20 parts, pp Fiber: 2 parts; in this embodiment, the cement used is 425 cement, and the water-retaining agent used is sodium polyacrylate-sodium polyacrylate.

[0030] The amount of each raw material used in the production of 2000kg adhesive is: 425 cement: 898.2Kg, quartz sand: 998.0Kg, latex powder: 49.9Kg, polyacrylamide-polyacrylamide: 4.0Kg, wood fiber: 6.0Kg, calcium formate 39.9Kg, pp fiber: 4.0Kg.

[0031] The preparation method is as follows: first pour 425 cement into the production equipment and stir for 5 minutes, and then mix quartz sand, latex powder, polyacrylamide-polyacrylamide, wood fiber, calcium formate and pp fiber under the condition of stirring Add it into the production equipment and stir at the same time. After the mixing is uniform,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com