Preparation method of manganese copper alloy material

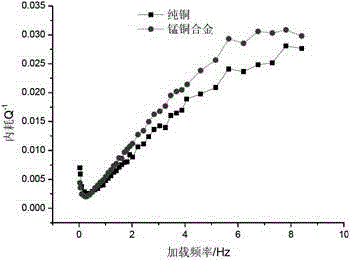

A manganese-copper alloy, high-purity copper technology, applied in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of reducing the performance of materials, easy introduction of impurities in energy, long production cycle, etc., to enhance damping performance, avoid Reduction of crystal structure defects and mechanical properties, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

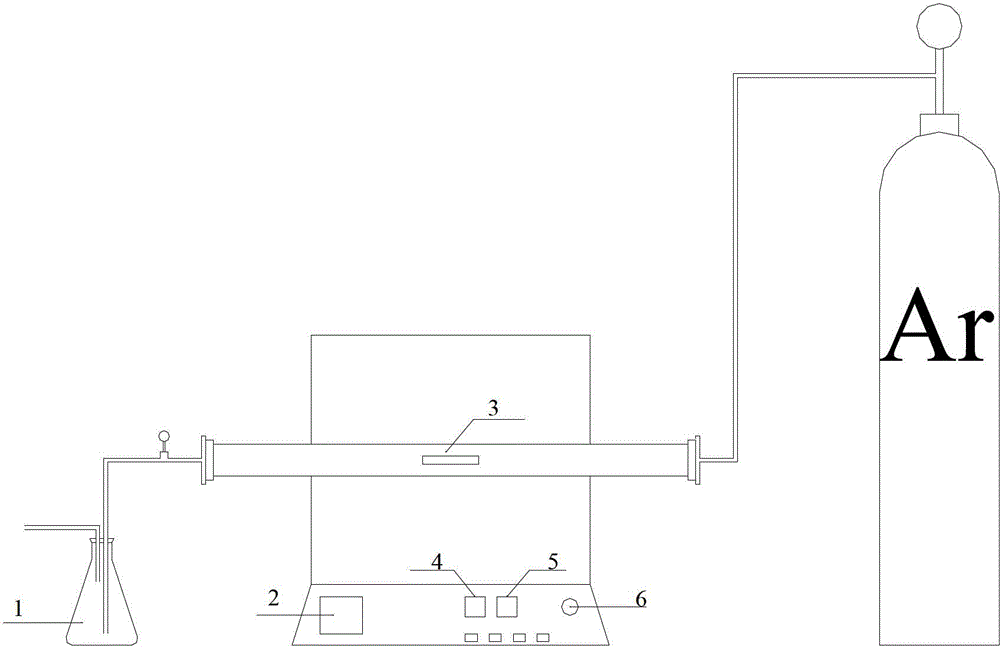

[0023] Adopt following method to process in the preparation method of the present invention:

[0024] (1) Pre-grinding treatment of the stainless steel substrate: The stainless steel substrate was polished and polished sequentially with 320 mesh, 500 mesh, and 1000 mesh golden sandpaper until the surface was bright and scratch-free.

[0025] (2) Degreasing treatment of stainless steel substrate: electrolytic degreasing treatment is performed on the stainless steel substrate material, and the degreasing electrolyte formula: NaOH10g / L, NaOH 2 CO 3 35g / L, NaPO 3 40g / L, electrolysis temperature 65℃. The anode is ordinary stainless steel, the cathode is 304 stainless steel, and the current density is 6A / dm 2 After 6 minutes of electrolysis, exchange the positive and negative electrodes and continue electrolysis for 1 minute.

[0026] (3) Pickling activation treatment: Pickling activation is performed on the stainless steel after degreasing treatment, and the pickling liquid for...

Embodiment 1

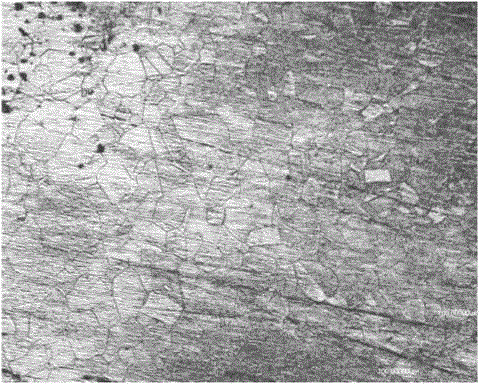

[0038] After the stainless steel substrate is polished and polished, it is activated by alkali cleaning, degreasing and acid cleaning, and the current density is 6-8A / dm 2 Electrodeposit copper for 7-8 hours, current density 14-16A / dm 2 Electrodeposit manganese for 30 minutes, heat treatment at 850°C for 5 hours. The manganese content is 17.78%, the copper content is 82.22%, the grain size is 50.36μm, and the microhardness is 217.33HV.

Embodiment 2

[0040] After the stainless steel substrate is polished and polished, it is activated by alkali cleaning, degreasing and acid cleaning, and the current density is 5-6A / dm 2 Electrodeposit copper for 4-5 hours; current density 16-18A / dm 2 Electrodeposit manganese for 15 minutes, heat treatment at 600°C for 8 hours. The manganese content is 18.07%, the copper content is 81.93%, the grain size is 73.65μm, and the microhardness is 243.10HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com