Accurate calibration method of film coating rate and application thereof

A calibration method and rate technology, applied in the direction of optical devices, measuring devices, instruments, etc., to achieve the effect of simple method, poor signal-to-noise ratio, and improved calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The accurate calibration method of the coating rate in this embodiment takes the film 2 to be measured as SiO2 (refractive index is about 1.46) as an example.

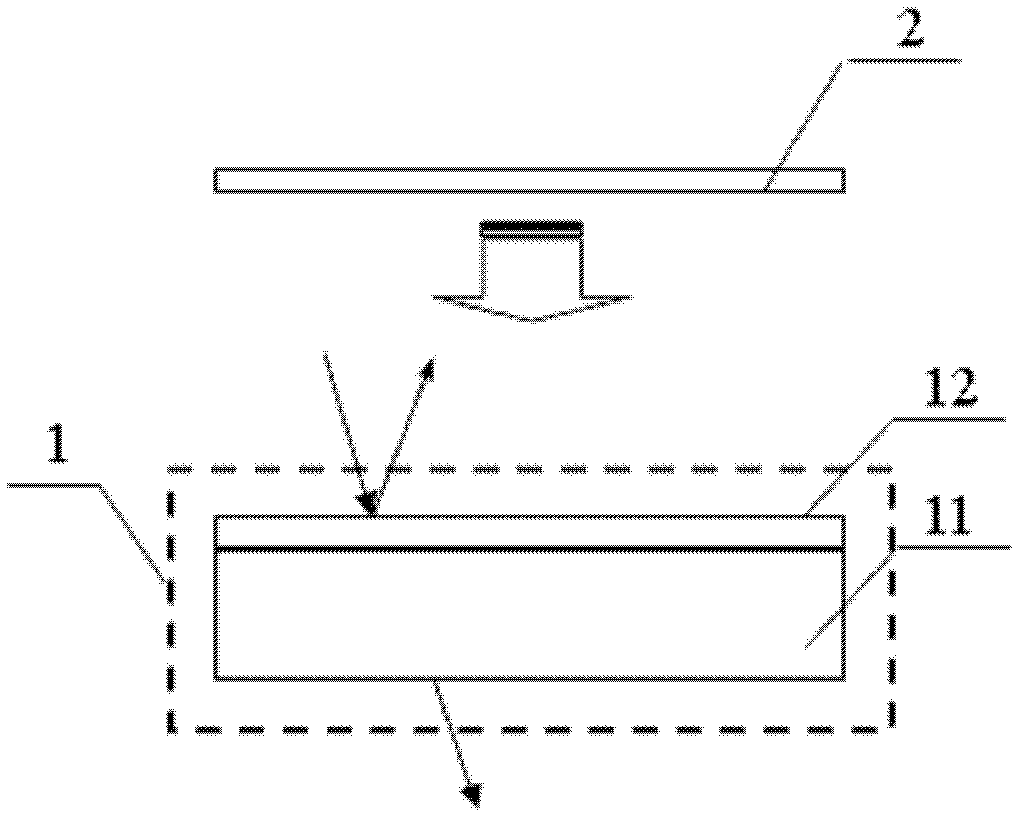

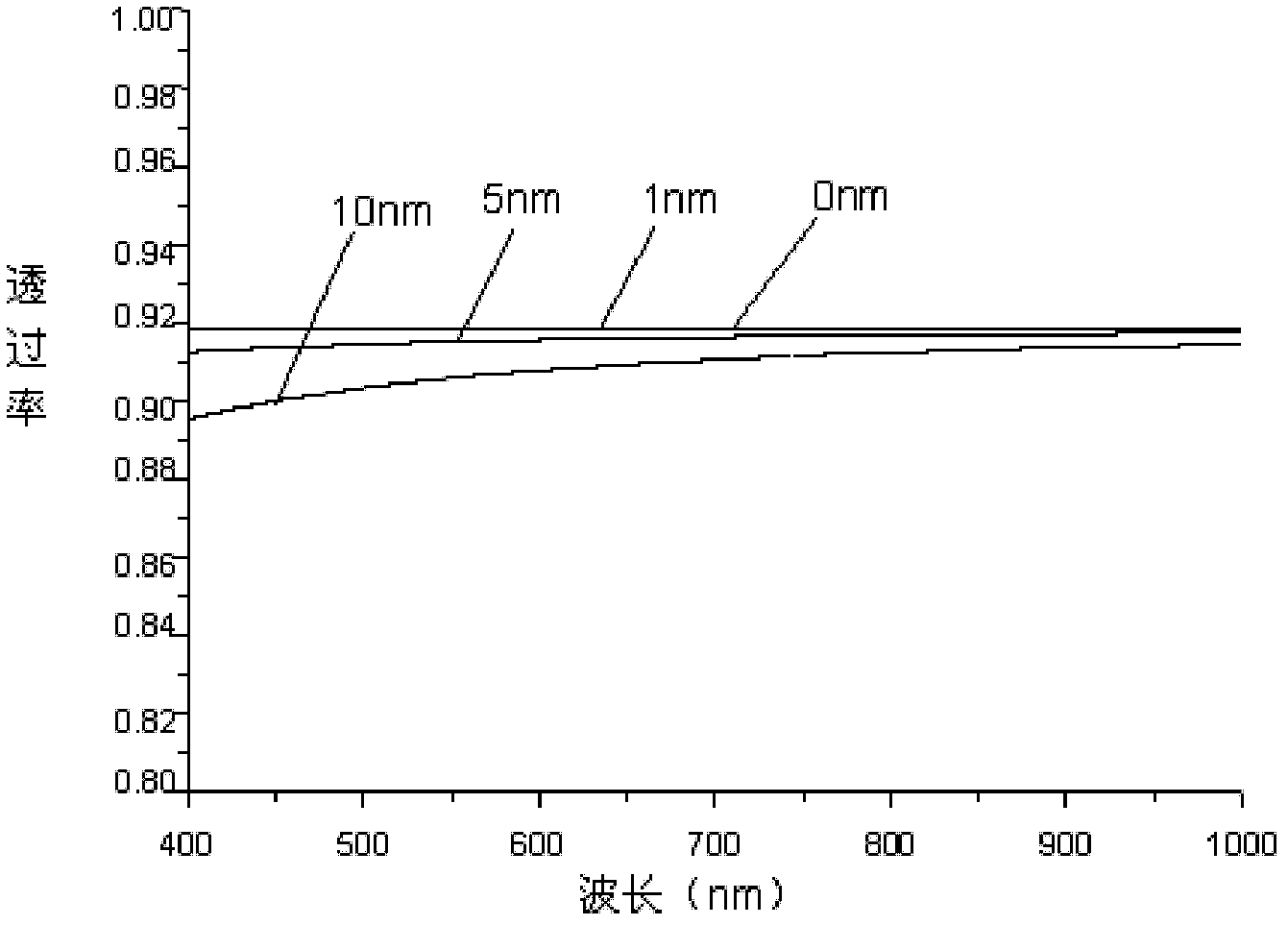

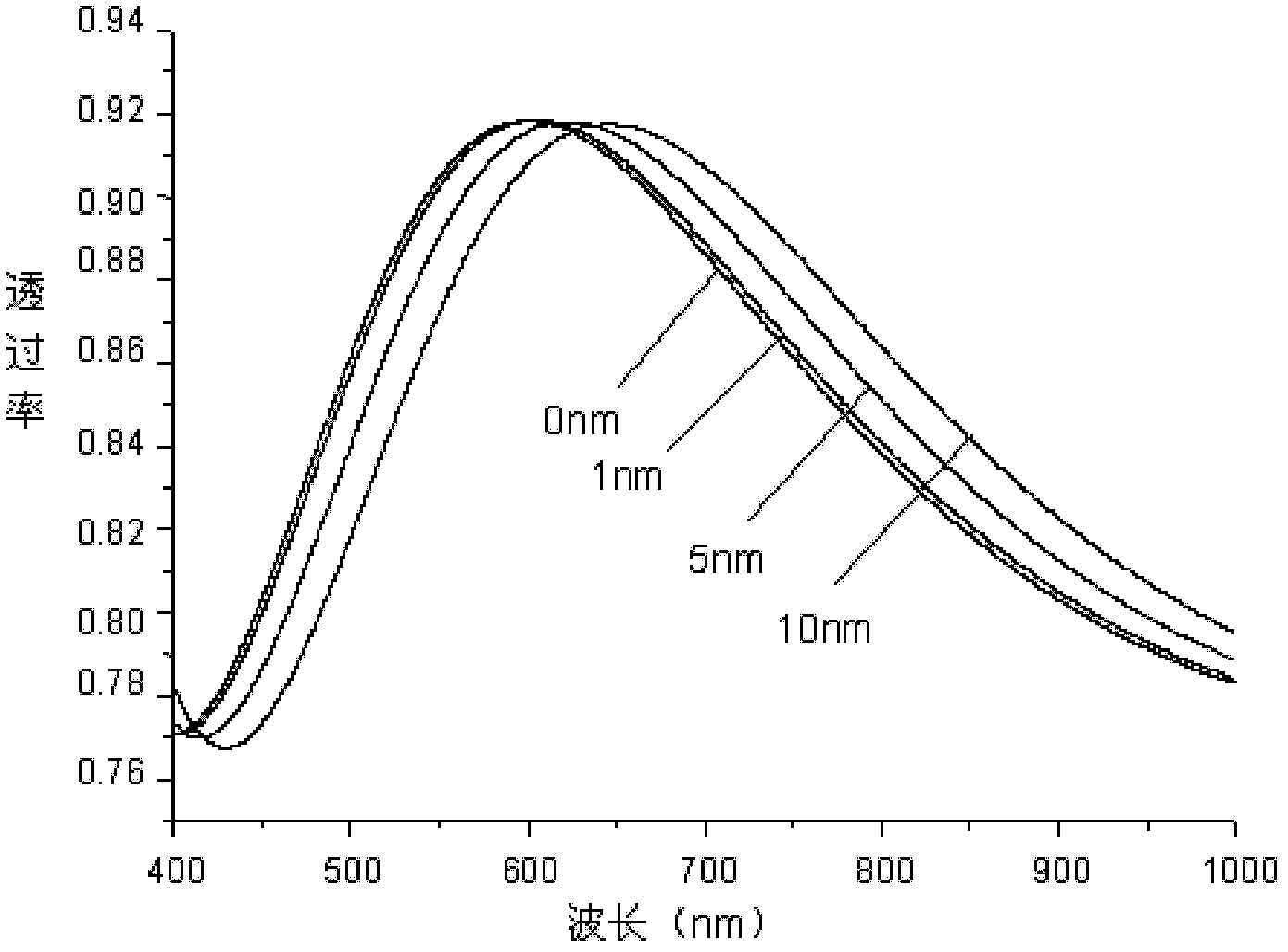

[0044] Step ①: Prepare standard substrate 1; see figure 1 , the standard substrate 1 includes a substrate 11 and an interference film 12; the preparation method is: on the substrate 11, a layer of interference film 12 sufficient to form interference is introduced; the refractive index of the substrate 11 of the standard substrate 1 is different from that of the interference film 12 , and the greater the difference in refractive index, the better. The thickness of the interference film 12 of the standard substrate 1 makes the interference film 12 produce only one-order interference in the 400-1000nm band, at this time the interference peak can obtain the largest shift, and the change caused by the thickness is the most obvious. When the thickness of the interference film is constant, the smaller the refractive i...

Embodiment 2

[0063] In this embodiment, SiO2 plating is still taken as an example, and the basic calibration method is as in Example 1, except that the SiO2 thin film of the rate to be measured is plated for 5 minutes. front and rear transmission spectra as Figure 9 As shown, the calculation can be obtained: the interference peak displacement is 81.9nm, the thickness fitting result is 56.1nm, and the plating rate is 11.2nm / min. The result of this embodiment shows that when the film to be tested is thicker or the coating rate is higher, the application method of the present invention is still effective.

Embodiment 3

[0065] This embodiment still takes the SiO2 plating as an example, the basic calibration method is as in Example 1, the difference is: the SiO2 film of the rate to be measured is plated by a vacuum evaporation coating system for 10 seconds, and the plating is carried out according to the following steps:

[0066] 1) Clean the tungsten wire, slide glass and crucible.

[0067] 2) Check the fixation of the tungsten wire and the position of the electrode in the bell jar, add quartz sand into the crucible, and put it into the crucible.

[0068] 3) Evacuate until the vacuum reaches above 1.5x10-2Pa, and start to evaporate the coating.

[0069] 4) After the coating is completed, deal with the follow-up work of the vacuum unit.

[0070] After coating the SiO2 thin film whose rate is to be measured, measure the transmission spectrum or reflection spectrum again, and the front and rear transmission spectra are as follows: Figure 10 shown. Then, the multi-peak decomposition and fitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com