Resinous tungsten composite material prescription and manufacturing process thereof

A technology of composite materials and manufacturing process, applied in the field of radiation-resistant composite materials, can solve social and environmental hazards, environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

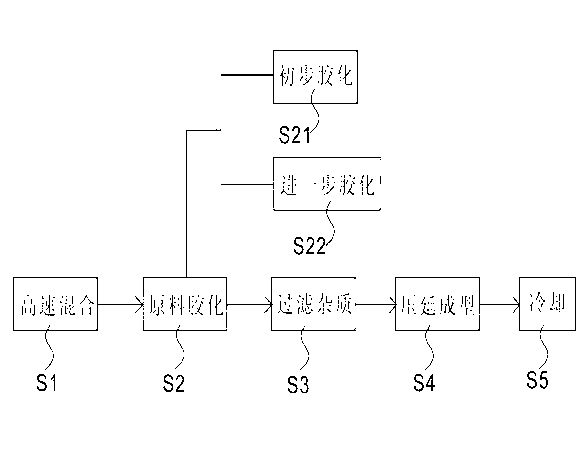

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, Embodiment 1 of the present invention A resin tungsten composite material formulation, prepared from the following raw materials by weight percentage:

[0031] Element Tungsten powder Nitrile rubber Chlorinated polyethylene stearic acid Acrylic Copolymer Proportion 98% 0.75% 0.75% 0.4% 0.1%

[0032] ;

[0033] And, the resin tungsten composite material prepared by tungsten powder, nitrile rubber, chlorinated polyethylene, stearic acid and acrylate copolymer has a density of 11.0g / cm 3 ~12.5 g / cm 3 between. Wherein, the tungsten powder is a non-ferrous metal tungsten powder with a particle size of 1 micron to 3 microns and a purity of more than 99.98%.

Embodiment 2

[0034] Embodiment 2, Embodiment 2 of the present invention A resin tungsten composite material formula, prepared from the following raw materials by weight percentage:

[0035] Element Tungsten powder Nitrile rubber Chlorinated polyethylene stearic acid Acrylic Copolymer Proportion 92% 0.75% 3.75% 2% 1.5%

[0036] ;

[0037] And, the resin tungsten composite material prepared by tungsten powder, nitrile rubber, chlorinated polyethylene, stearic acid and acrylate copolymer has a density of 11.0g / cm 3 ~12.5 g / cm 3 between. Wherein, the tungsten powder is a non-ferrous metal tungsten powder with a particle size of 1 micron to 3 microns and a purity of more than 99.98%.

Embodiment 3

[0038] Embodiment 3, a resin tungsten composite material formula in Embodiment 3 of the present invention, prepared from the following raw materials by weight percentage:

[0039] Element Tungsten powder Nitrile rubber Chlorinated polyethylene stearic acid Acrylic Copolymer Proportion 94% 3.75% 1% 0.1% 1.15%

[0040] And, the resin tungsten composite material prepared by tungsten powder, nitrile rubber, chlorinated polyethylene, stearic acid and acrylate copolymer has a density of 11.0g / cm 3 ~12.5 g / cm 3 between. Wherein, the tungsten powder is a non-ferrous metal tungsten powder with a particle size of 1 micron to 3 microns and a purity of more than 99.98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com