Substrate processing apparatus

A substrate processing device and processing device technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of long path, large power loss, poor matching, etc., and achieve suppressed power loss, small fluctuation rate, The effect of small current difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

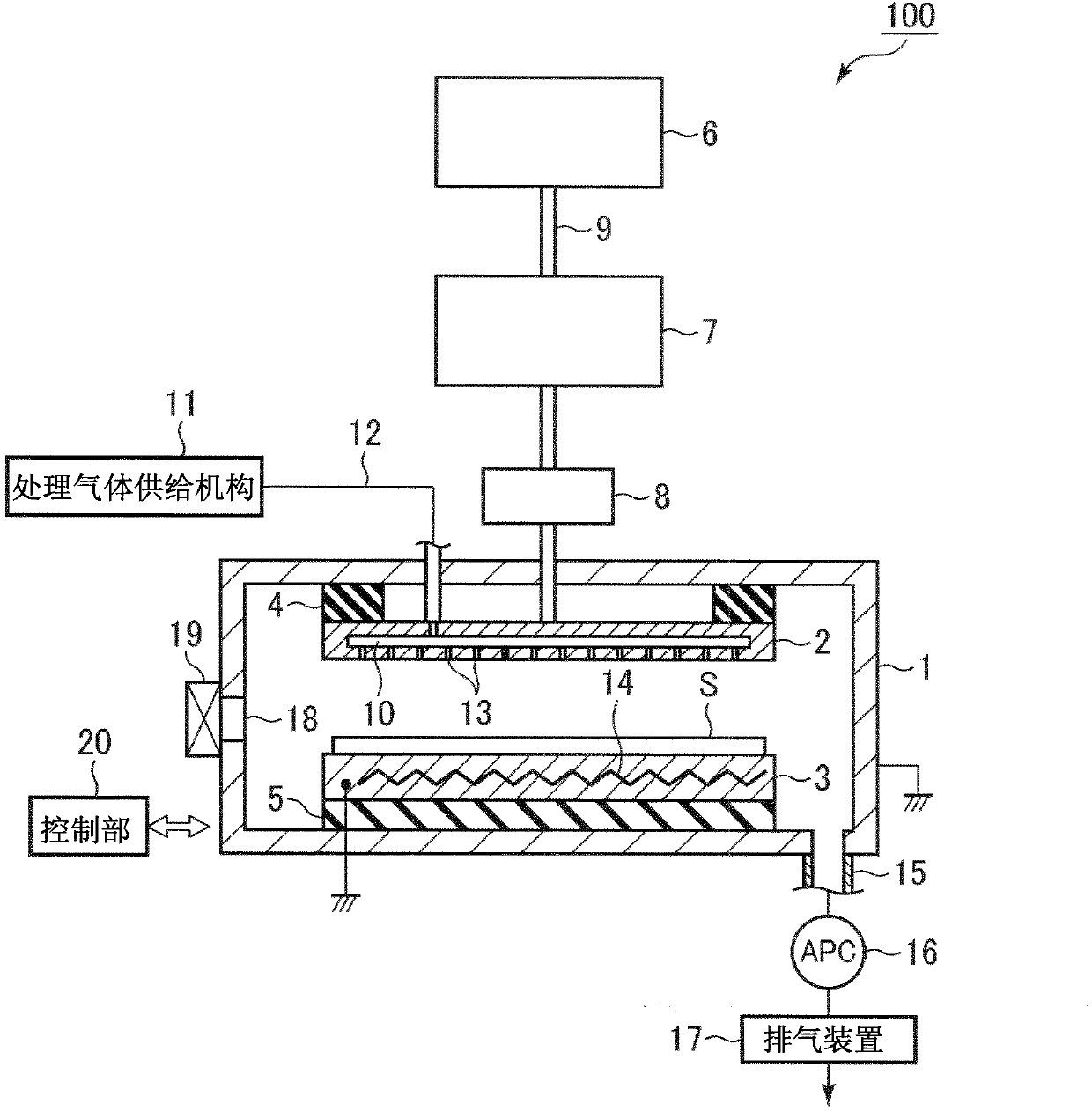

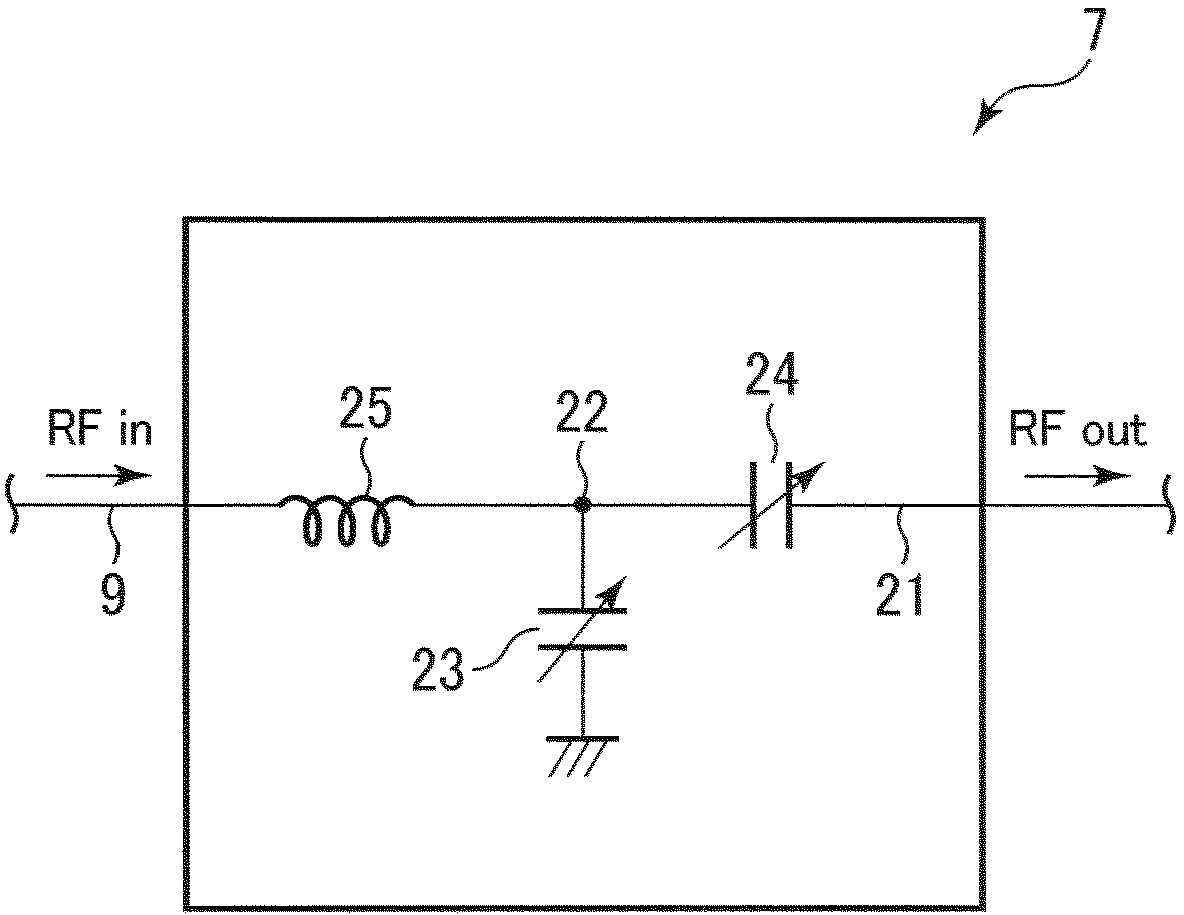

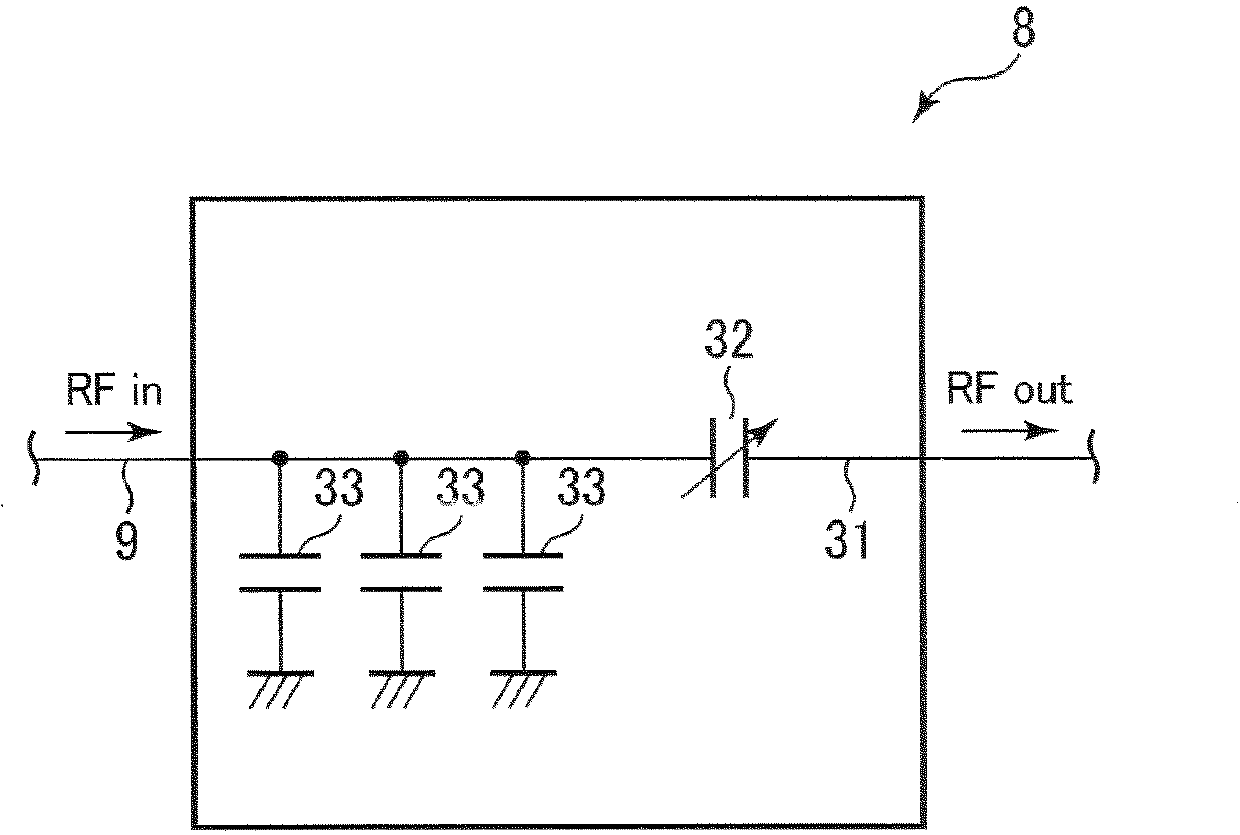

[0051] First, a first embodiment will be described. figure 1 It is a sectional view showing the substrate processing apparatus according to the first embodiment of the present invention.

[0052] The substrate processing apparatus 100 is configured as a parallel plate type plasma processing apparatus that performs plasma processing on a substrate. This substrate processing apparatus 100 accommodates a substrate S and has a chamber 1 for performing plasma processing. Chamber 1 is safely grounded.

[0053] A cathode electrode 2 and an anode electrode 3 constituting parallel plate electrodes are arranged in the chamber 1 . The cathode electrode 2 is configured as an upper electrode, and functions as a plasma generation electrode supplied with high-frequency power. In addition, the cathode electrode 2 functions as a shower head for introducing process gas into the chamber 1 . On the other hand, the anode electrode 3 is configured as a lower electrode, and functions as a mounti...

no. 2 approach )

[0070] Next, a second embodiment will be described. Figure 4 It is a schematic diagram showing the substrate processing apparatus of the second embodiment. The basic structure of the substrate processing apparatus 100 ′ of this embodiment is the same as that of the substrate processing apparatus 100 of the first embodiment. Figure 4 right with figure 1 The same reference numerals are assigned to the same parts, and explanations thereof are omitted.

[0071] This embodiment differs from the first embodiment in that two impedance adjustment circuits 8a, 8b are provided, and power is supplied from mutually opposing feeding points on both sides of the cathode electrode via these impedance adjustment circuits 8a, 8b.

[0072] Specifically, the transmission path 9 extending downward from the matching unit 7 is branched into the transmission paths 9a and 9b, and connected to the power supply points on both sides of the cathode electrode 2 facing each other, and impedances are res...

no. 3 approach )

[0078] Next, a third embodiment will be described. Figure 5 It is a schematic diagram showing the substrate processing apparatus of the third embodiment. The substrate processing apparatus 200 of the present embodiment is basically a substrate processing apparatus in which the substrate processing apparatus 100 of the first embodiment is applied to an apparatus (batch type apparatus) that performs plasma processing on a plurality of substrates. Thus, in Figure 5 In the pair with figure 1 The parts with the same functions are denoted by the same reference numerals for description.

[0079] The substrate processing apparatus 200 is configured as a parallel plate type plasma processing apparatus for performing plasma processing on a plurality of substrates, and accommodates a plurality (in Figure 5 There are three substrates S with a chamber 1 for plasma processing. The chamber 1 is safely grounded as in the first embodiment.

[0080] In the chamber 1, a plurality of pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com