Light source cooling structure

A heat dissipation structure and light source technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the service life of LEDs, the light decay of LEDs, and the efficiency of lighting, so as to maintain the service life, reduce the impact, increase The effect of heat dissipation cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

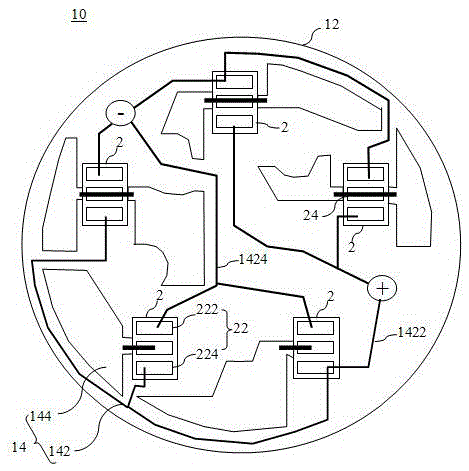

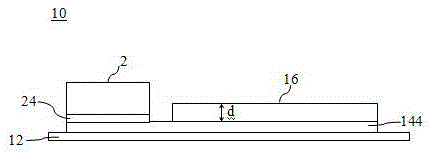

[0040] figure 1 It is a schematic layout diagram of the heat dissipation structure of the light source in Embodiment 1 of the present invention. Such as figure 1 As shown, the light source heat dissipation structure 10 can dissipate heat energy generated when the light source 2 (such as a light emitting diode) emits light. Wherein, the bottom of the light source 2 generally has an electrical contact 22 of at least one of the positive end 222 and the negative end 224 , and a heat dissipation contact 24 . The electrical contact 22 can obtain the power supply PW required to drive the light source 2 to emit light from a transformer, commercial power, primary battery or secondary battery. In another embodiment, the negative end 224 of the light source 2 may replace the heat dissipation contact 24 , so that the light source only has the positive end 222 and the negative end 224 .

[0041] The light source heat dissipation structure 10 includes a heat dissipation substrate 12 , a ...

Embodiment 2

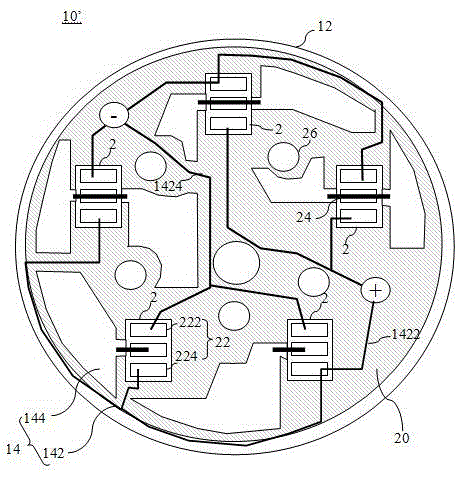

[0050] image 3 It is a schematic layout diagram of the heat dissipation structure of the light source in Embodiment 2 of the present invention. image 3 Among them, the light source heat dissipation structure 10' can also dissipate the heat energy generated when the light source 2 emits light, and the light source heat dissipation structure 10' includes the heat dissipation substrate 12, the layout layer 14 and the heat dissipation diffusion layer 16 in Embodiment 1. In addition, it also includes an insulating layer 18 , a heat dissipation coating layer 20 and a hole 26 .

[0051] Wherein, the insulating layer 18 is formed between the heat dissipation substrate 12 and the layout layer 14 to block the electrical conduction between the heat dissipation substrate 12 and the layout layer 14 . It should be noted that the insulating layer 18 is not an essential part. For example, if the heat dissipation substrate 12 is made of non-metallic material, the insulating layer 18 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com