Tinidazole injection preparation and preparation method thereof

A technology of tinidazole and injection, which is applied in the field of medicine, can solve the problems affecting the quality of finished products and the pass rate, and the decrease of tinidazole content, and achieve the effects of facilitating mass production, simple prescription, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

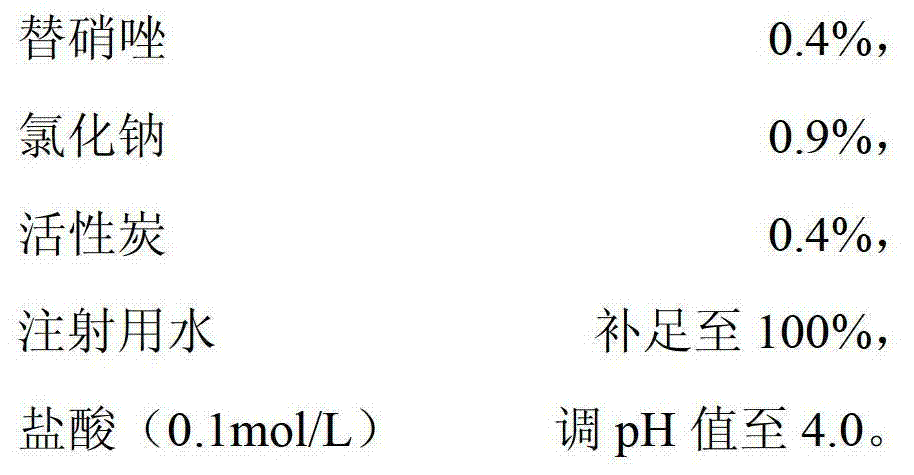

[0024] A kind of tinidazole injection preparation, it comprises the component that comprises following percentage by weight:

[0025]

[0026] The production method is as follows:

[0027] (1) Weigh 30% water for injection of the formula and cool to 30°C;

[0028] (2) Weigh the formula amount of osmotic pressure regulator sodium chloride and dissolve it in the cooled fresh water for injection in step (1);

[0029] (3) Weigh 50% of the adsorbent activated carbon of the formula and add it to the solution obtained in step (2), boil and adsorb for 15 minutes, remove the adsorbent, and add water for injection to the full amount;

[0030] (4) Keep the solution obtained in step (3) at 60±1°C, add the prescribed amount of tinidazole, stir to dissolve, measure the pH value, and adjust the pH value to 4.0 with the pH adjusting additive hydrochloric acid (0.1mol / L) ;

[0031] (5) Add 50% of the formula amount of adsorbent activated carbon to the solution obtained in step (4), stir ...

Embodiment 2

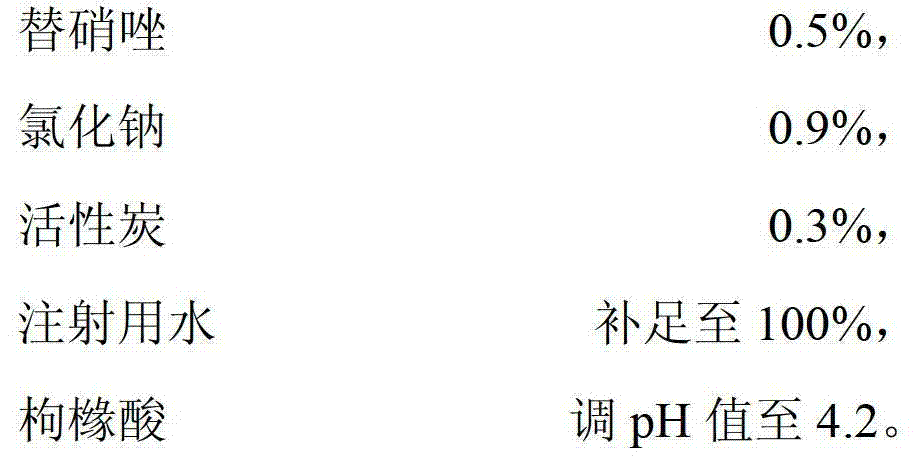

[0033] A kind of tinidazole injection preparation, it comprises the component that comprises following percentage by weight:

[0034]

[0035] The production method is as follows:

[0036] (1) Weigh 30% water for injection of the formula and cool to 40°C;

[0037] (2) Weigh the formula amount of osmotic pressure regulator sodium chloride and dissolve it in the cooled fresh water for injection in step (1);

[0038] (3) Weigh 50% of the adsorbent activated carbon of the formula and add it to the solution obtained in step (2), boil and adsorb for 30 minutes, remove the adsorbent, and add water for injection to the full amount;

[0039] (4) Keep the solution obtained in step (3) at 60±1°C, add the prescribed amount of tinidazole, stir to dissolve, measure the pH value, and adjust the pH value to 4.2 with the pH adjusting additive hydrochloric acid (0.1mol / L) ;

[0040] (5) Add 50% of the formula amount of adsorbent activated carbon to the solution obtained in step (4), stir ...

Embodiment 3

[0047] Embodiment 3: the investigation result of finished product rate and raw material consumption rate

[0048] Adopt embodiment 1, 2, comparative example 1, 2, 3 and present conventional process method (conventional method namely, add appropriate amount of water for injection, stir and drop into the sodium chloride of recipe quantity, sodium chloride is mixed with 20% solution, Add 0.3% activated carbon for needles, boil for 10 minutes, decarburize after cooling slightly. Heat the water for injection to the full amount, add the prescribed amount of tinidazole, stir to dissolve, measure the pH value, adjust the pH to 4.0~ with 0.1mol / l hydrochloric acid 4.2, add 0.02% (W / V) 767# activated carbon for needles, take a sample to measure the content of the semi-finished product, pH value, and transport the tinidazole injection (according to 100L volume) to the filling room after the visible foreign matter is qualified. ) product yield and raw material consumption rate are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com