Complete equipment for extracting phenols in medium and low temperature coal tar

A technology of low-temperature coal tar and complete equipment, which is applied in the direction of preparation of organic compounds, liquid solution solvent extraction, chemical instruments and methods, etc., can solve the problems of low-temperature coal tar that cannot be processed by high-temperature coal tar processing, and achieve energy saving in operation and cost, significant energy saving and emission reduction, and the effect of fine separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

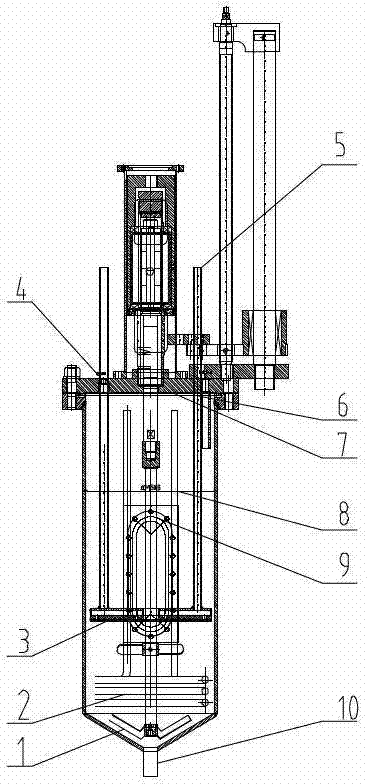

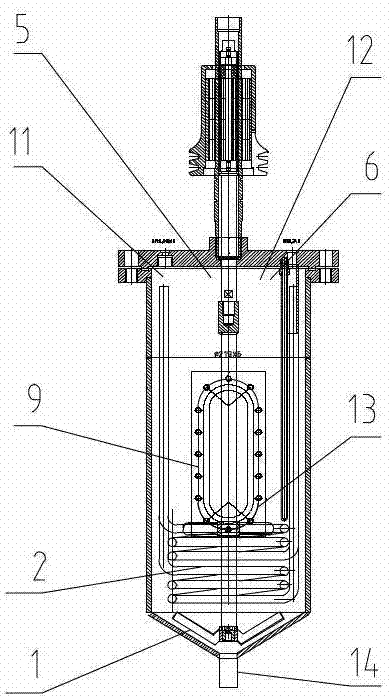

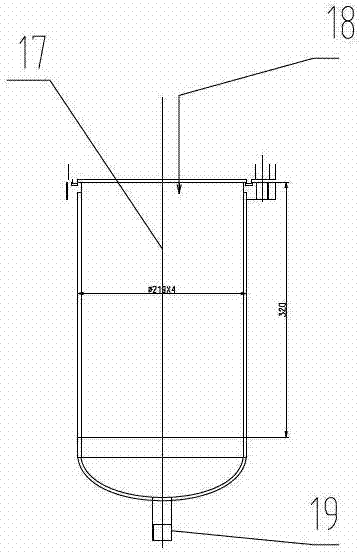

[0037] Example 1: A complete set of equipment for extracting phenol from medium and low temperature coal tar, which consists of five kettles, four tanks and three sets of condensers; they are respectively medium and low temperature coal tar extraction and separation kettle 8; extraction light oil No. 1 extraction agent is concentrated Kettle 13; No. 1 solvent tank 17; No. 2 extraction agent concentration kettle 20 for extracting crude phenol; No. 2 solvent tank 26; No. 3 solvent extraction and refining crude phenol kettle 29; extraction and refining crude phenol filter tank 34; extraction and refining crude phenol No. 3 Extractant concentration tank 36; No. 3 solvent tank 43 and No. 1 condenser 45-1, No. 2 condenser 45-2 and No. 3 condenser 45-3.

[0038] exist Figure 11 Middle and low temperature coal tar extraction and separation kettle 8, the upper right outlet 7 is connected with the left upper side inlet 11 of extraction light oil No. The discharge port 10 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com