Microfluidic experimental device for studying dynamic process of acoustic and electric field filter aid

A dynamic process and experimental device technology, applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve problems such as the inability to study the mechanism of acoustic electric field filtration, and achieve easy observation and mechanism research, easy Combined use, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

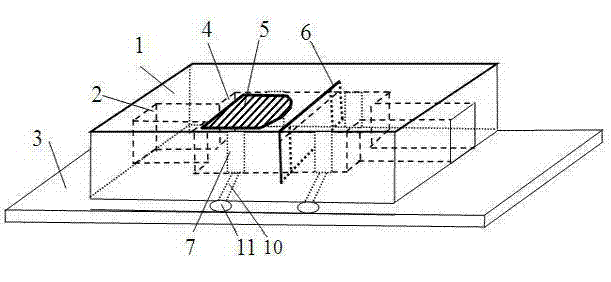

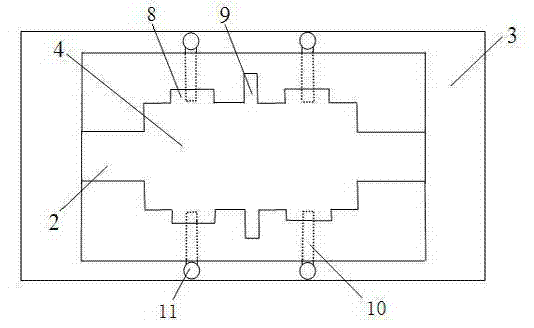

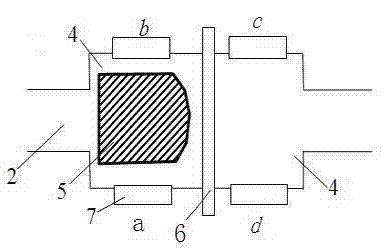

[0022] see figure 1 , is a schematic diagram of the overall structure of a microfluidic experimental device used for the study of the dynamic process of acoustic and electric field filtration in the present invention. The millimeter-scale microfluidic chip 1 is made of dimethylsiloxane (PDMS) material by molding method, This ensures that the entire millimeter-scale microfluidic chip 1 has good light transmittance, which is convenient for observation under microscopic conditions. The bottom of the millimeter-scale microfluidic chip 1 is pasted on the sealing film 3, the middle of the millimeter-scale microfluidic chip 1 is a reaction chamber 4, and the middle of the left and right sides of the reaction chamber 4 is a microchannel 2 communicating with the reaction chamber 4. The microchannel 2 is used for the pressure transmission of the sample, and transmits the experimental sample into the reaction chamber 4 . The upper and lower heights of the microchannel 2 are 5 mm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com