Novel ultrasonic wave sensor

An ultrasonic and sensor technology, applied in the field of sensors, can solve problems such as low sensitivity, large aftershocks, and small amplitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

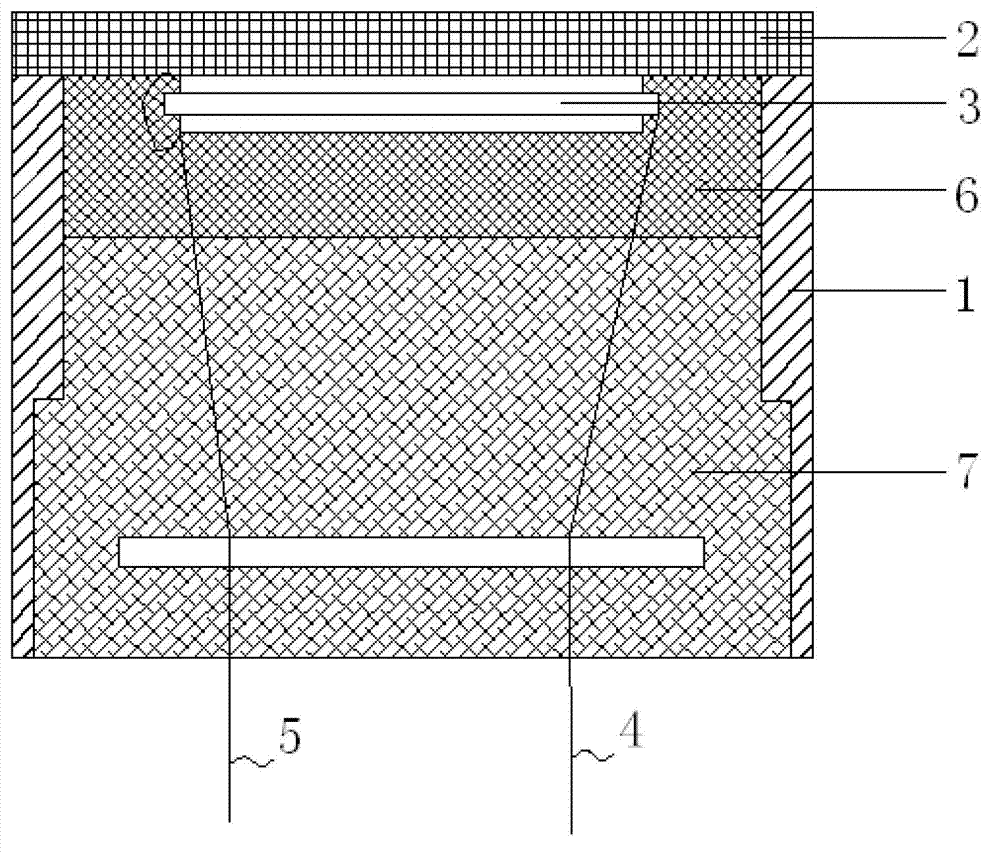

[0017] Such as figure 1 As shown, the novel ultrasonic sensor of the present invention includes a hollow metal casing 1, one end of the metal casing 1 is covered with a matching layer 2, and a parallel piezoelectric bimorph 3 is glued inside the matching layer 2. The matching layer 2 and the piezoelectric sheet are directly bonded with glue, and the size, density, thermal expansion coefficient, elastic modulus, and Poisson's ratio of the matching layer must be matched with the piezoelectric sheet to determine the resonance frequency of the ultrasonic sensor.

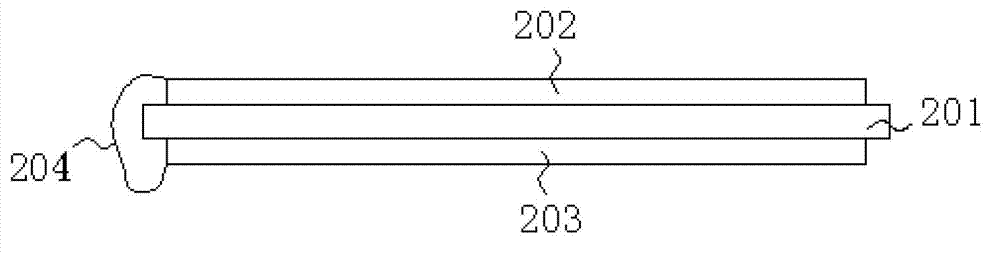

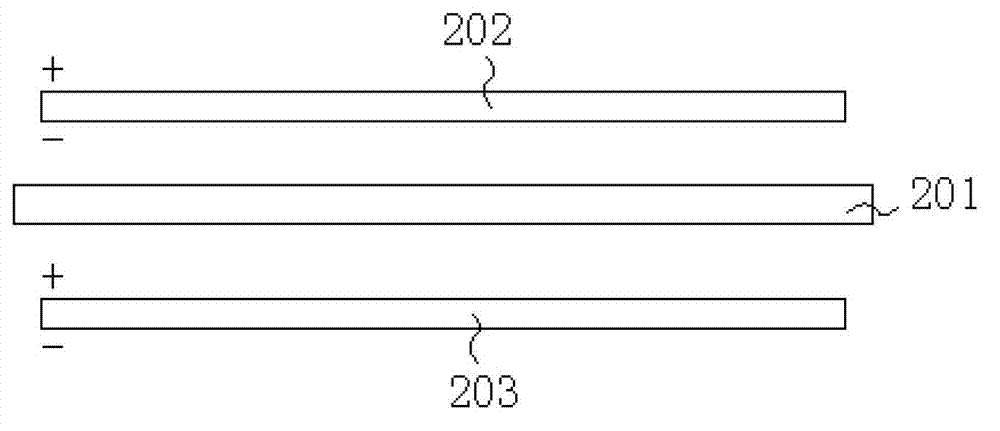

[0018] Such as figure 2 with image 3 As shown, the parallel piezoelectric bimorph 3 is to bond two opposite electrode surfaces of two piezoelectric wafers to both sides of a metal substrate, that is, the negative electrode surface of the first piezoelectric ceramic sheet 202 and the metal substrate 201 The upper surface is bonded; the positive side of the second piezoelectric ceramic sheet 203 is bonded to the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com