Multi-focal laser processing system

A laser processing and multi-focus technology, applied in the laser field, can solve problems such as damage, transverse cracks on the workpiece, and reduce the efficiency of laser equipment, so as to achieve the effects of improving product quality, increasing processing speed, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the technical solutions of the present invention, but are not intended to limit the present invention.

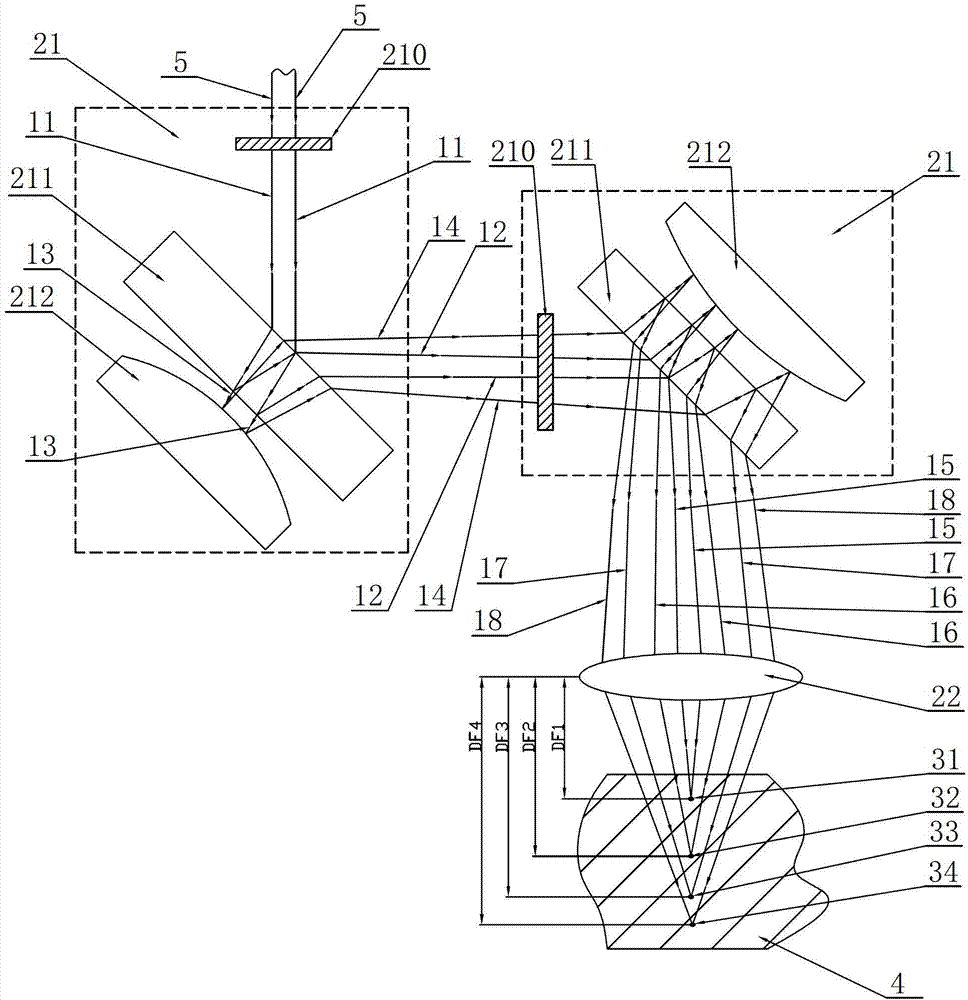

[0019] The four-focus laser processing system in the present invention includes two optical element combinations 21 and a focusing mirror 22 serially connected in series on the optical path. The optical element combination 21 includes a wave plate 210 , a beam splitter 211 and a convex mirror 212 .

[0020] The detailed optical path diagram of the four-focus laser processing system in the present invention is as follows figure 1 Shown:

[0021] The first part: the incident light beam 5 passes through the optical element combination 21:

[0022] The incident light beam 5 passes through the wave plate 210 to obtain the first ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com