Method for improving gradation of machined sand

A machine-made sand and gradation technology, which is applied in the field of machine-made sand gradation improvement, can solve the problem of lack of intermediate particles and achieve the effect of improved gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

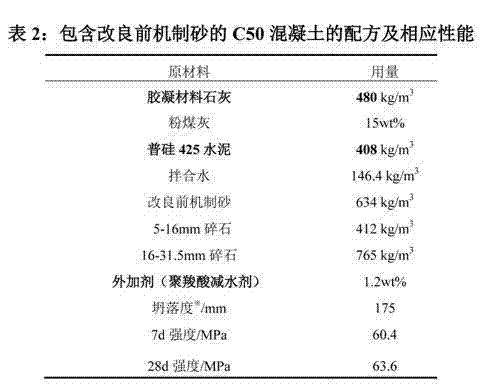

Embodiment 1

[0015] A method for improving the gradation of machine-made sand, comprising the following steps:

[0016] 1) Mix stone chips with a particle size of 0-4.75mm into the gravel with a particle size of 19-37.5mm, so that the stone chips with a particle size of 0-4.75mm are formed in the mixed material (that is, gravel and stone chips) The mass percentage in the mixed material) is 20%;

[0017] 2) Put it into the sand making machine to make sand, and then wash the sand to get the finished machine-made sand.

[0018] The finished machine-made sand (hereinafter referred to as improved machine-made sand) prepared by the above steps, and the finished machine-made sand obtained by completely using crushed stones with a particle size of 19-37.5mm, and then washing the finished machine-made sand (hereinafter referred to as Compared with the improved machine-made sand), the 1.18mm sieve residue in the finished machine-made sand was reduced from 49.8% to 44.1%, the content of fine particl...

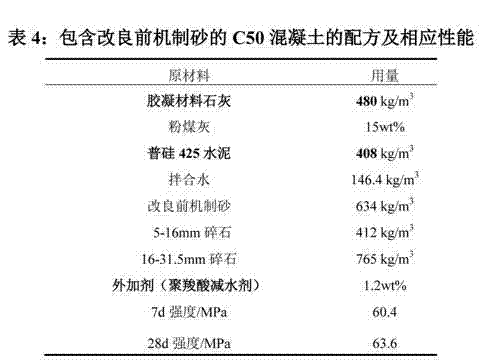

Embodiment 2

[0023] A method for improving the gradation of machine-made sand, comprising the following steps:

[0024] 1) Mix stone chips with a particle size of 0-4.75mm into the gravel with a particle size of 19-37.5mm, so that the stone chips with a particle size of 0-4.75mm are formed in the mixed material (that is, gravel and stone chips) The mass percentage in the mixed material) is 35%;

[0025] 2) Put it into the sand making machine to make sand, and then wash the sand to get the finished machine-made sand.

[0026] The finished machine-made sand (hereinafter referred to as improved machine-made sand) prepared by the above steps, and the finished machine-made sand obtained by completely using crushed stones with a particle size of 19-37.5mm, and then washing the finished machine-made sand (hereinafter referred to as Compared with the machine-made sand before improvement), the 1.18mm sieve residue in the finished machine-made sand was reduced from 49.8% to 42.5%, the content of fi...

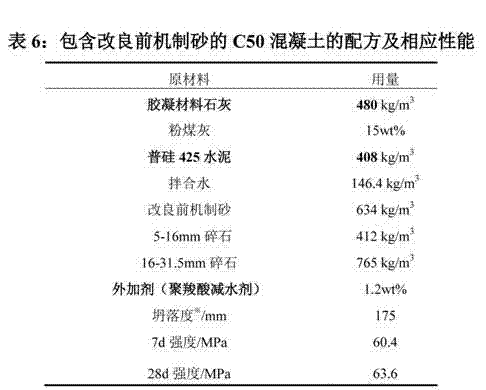

Embodiment 3

[0031] A method for improving the gradation of machine-made sand, comprising the following steps:

[0032] 1) Mix stone chips with a particle size of 0-4.75mm into the gravel with a particle size of 19-37.5mm, so that the stone chips with a particle size of 0-4.75mm are formed in the mixed material (that is, gravel and stone chips) The mass percentage in the mixed material) is 15%;

[0033] 2) Put it into the sand making machine to make sand, and then wash the sand to get the finished machine-made sand.

[0034] The finished machine-made sand (hereinafter referred to as improved machine-made sand) prepared by the above steps, and the finished machine-made sand obtained by completely using crushed stones with a particle size of 19-37.5mm, and then washing the finished machine-made sand (hereinafter referred to as Compared with the improved machine-made sand), the 1.18mm sieve residue in the finished machine-made sand was reduced from 49.8% to 46.4%, the content of fine particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com