A rotary transformer zero position tester

A resolver and tester technology, applied to the phase angle between voltage and current, instruments, measuring devices, etc., can solve problems such as difficulty in adjusting the angle of the resolver, unsuitability for mass production, difficulty in ensuring accuracy, etc., to improve Efficiency, easy to carry, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

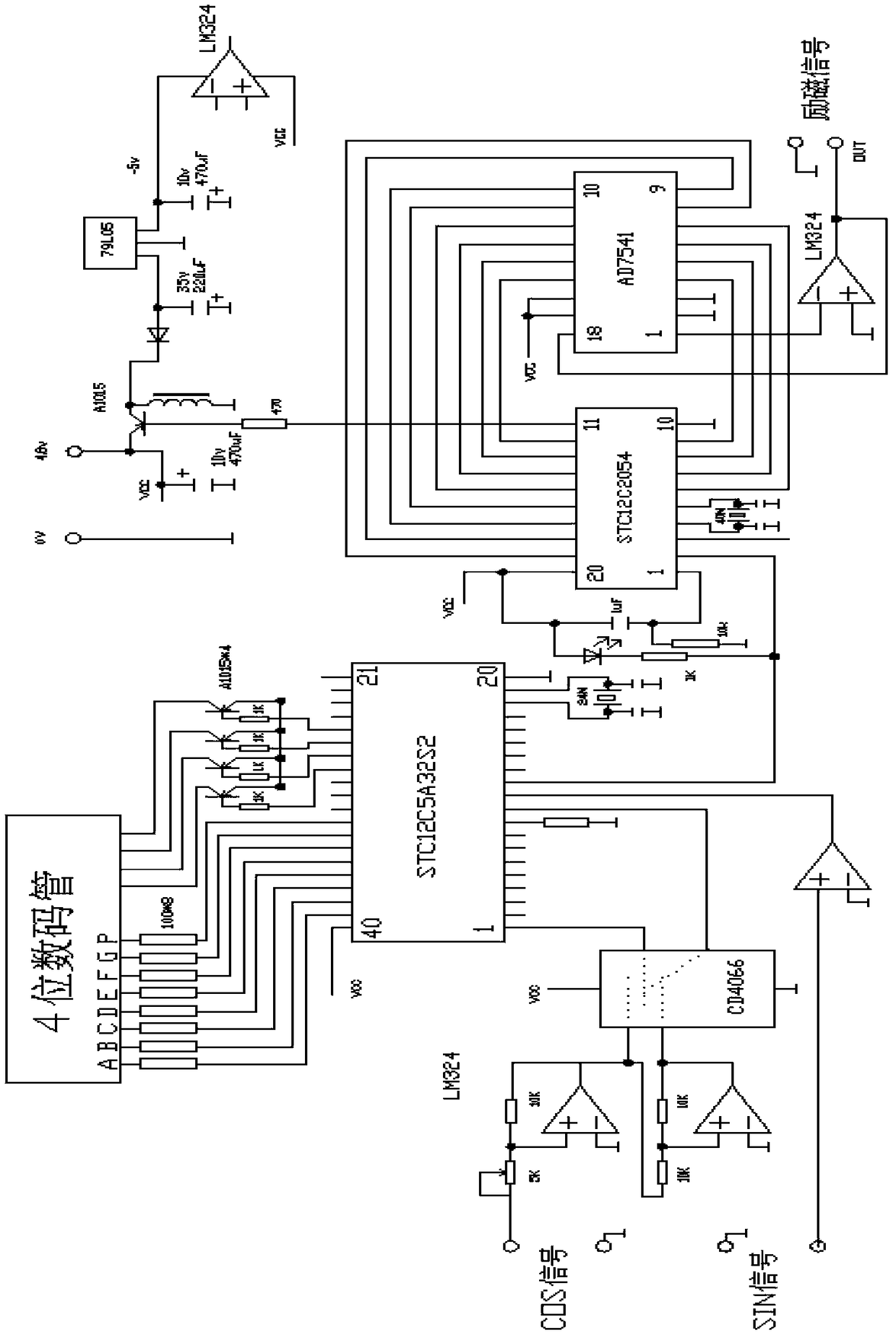

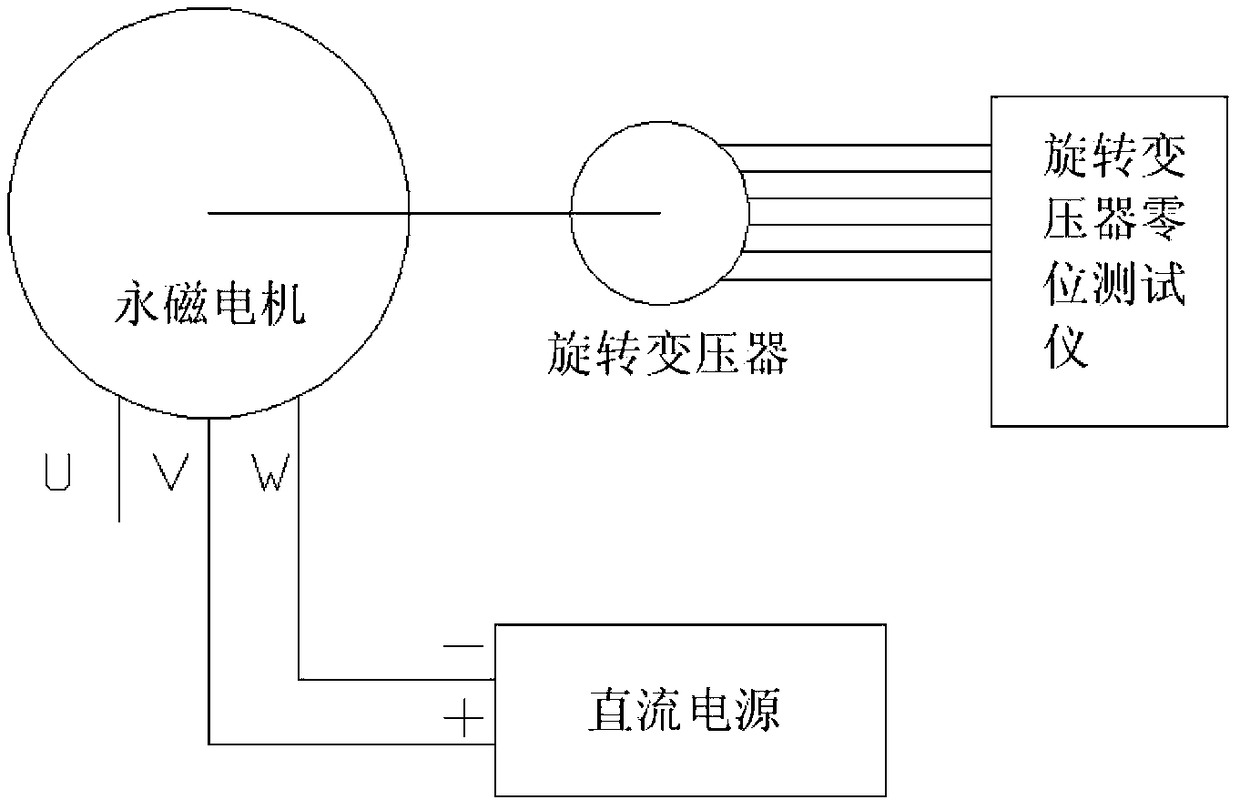

[0012] attached Figure 1-2 It is the resolver zero position tester of the present invention, comprising power supply, single-chip microcomputer, digital tube, COS signal acquisition circuit, SIN signal acquisition circuit, sine wave circuit; said single-chip microcomputer is STC12C5A32S2; said digital tube is 4 digital tubes The sine wave circuit includes STC12C2054 chip and AD7541 chip, the sine wave circuit produces a 3.5KHz sine wave, and the sine wave sends the excitation signal receiving end of the resolver; the COS signal acquisition circuit collects the signal of the resolver , send the CD4066 analog switch through the operational amplifier; the SIN signal acquisition circuit collects the signal of the rotary transformer, and sends the single-chip microcomputer to process through the operational amplifier; the single-chip micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com