Track optimization method for switching cannular polypropylene production marks

A technology of brand switching and trajectory optimization, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve problems such as multiple time nodes, increase the amount of calculation, and solve large-scale problems, so as to improve optimization efficiency, improve economic benefits, The effect of reducing brand switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

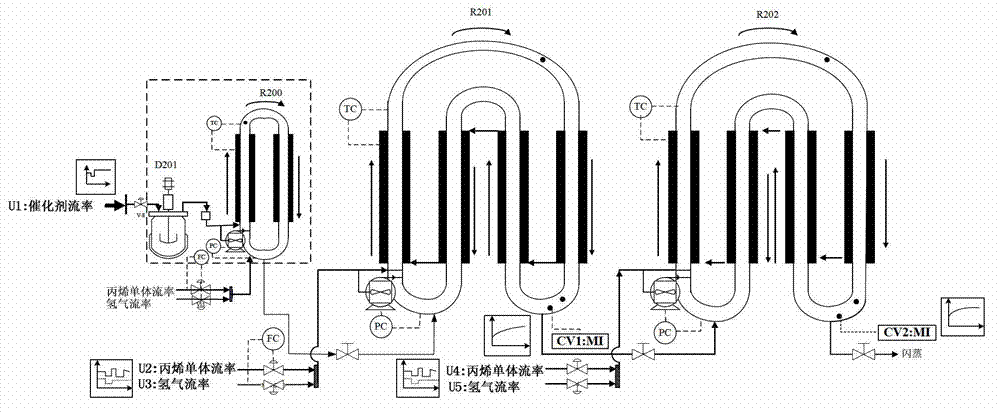

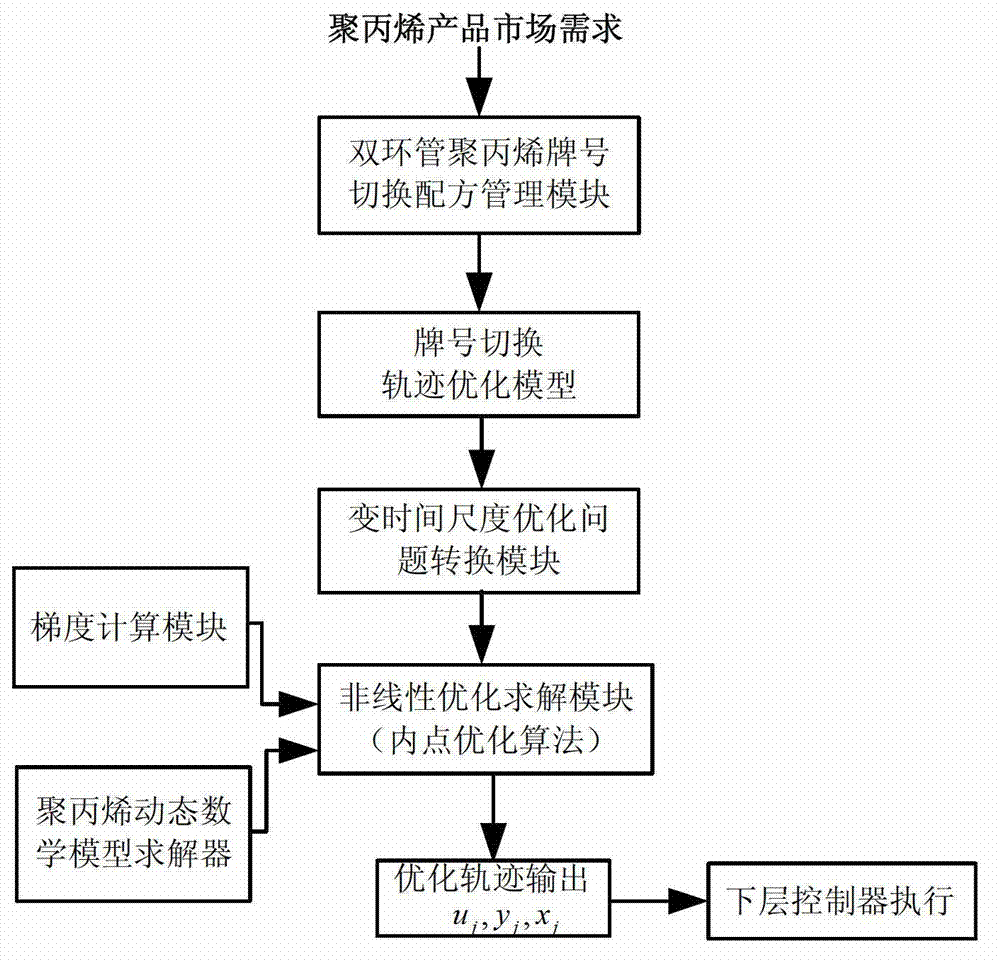

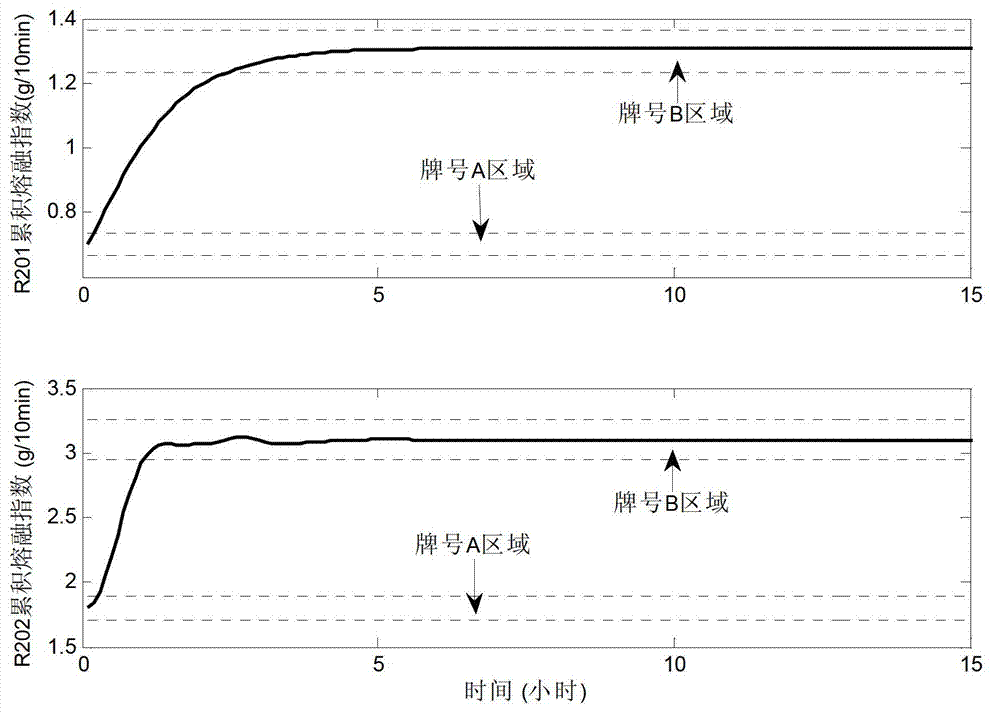

[0028] refer to figure 1 , figure 2 , Fig. 3(a), Fig. 3(b) a method for optimizing the switching trajectory of grades in the production of ring-pipe polypropylene, the specific implementation method is as follows:

[0029] (1) Use the 2# double-loop process liquid phase propylene bulk polymerization device of a branch company of Sinopec (such as figure 1 Shown) two grades of polypropylene (film grade S38F and wire drawing grade T30S, defined as grades A and B) are the objects (see Table 1). Based on the actual production conditions on site, determine the switching steady-state point and switching constraints of each brand (see Table 2), and give the double-loop pipe product quality index cumulative melt index switching qualification range of ±5%, and at the same time give the aggregation operation variable switching range Value and control increment constraints...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com