Three-level hysteresis current tracking inverter and control method of three-level hysteresis current tracking inverter

A three-level inverter and hysteresis current technology, which is applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of increased electromagnetic interference, inaccurate judgment, and difficulty in obtaining sufficient play and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

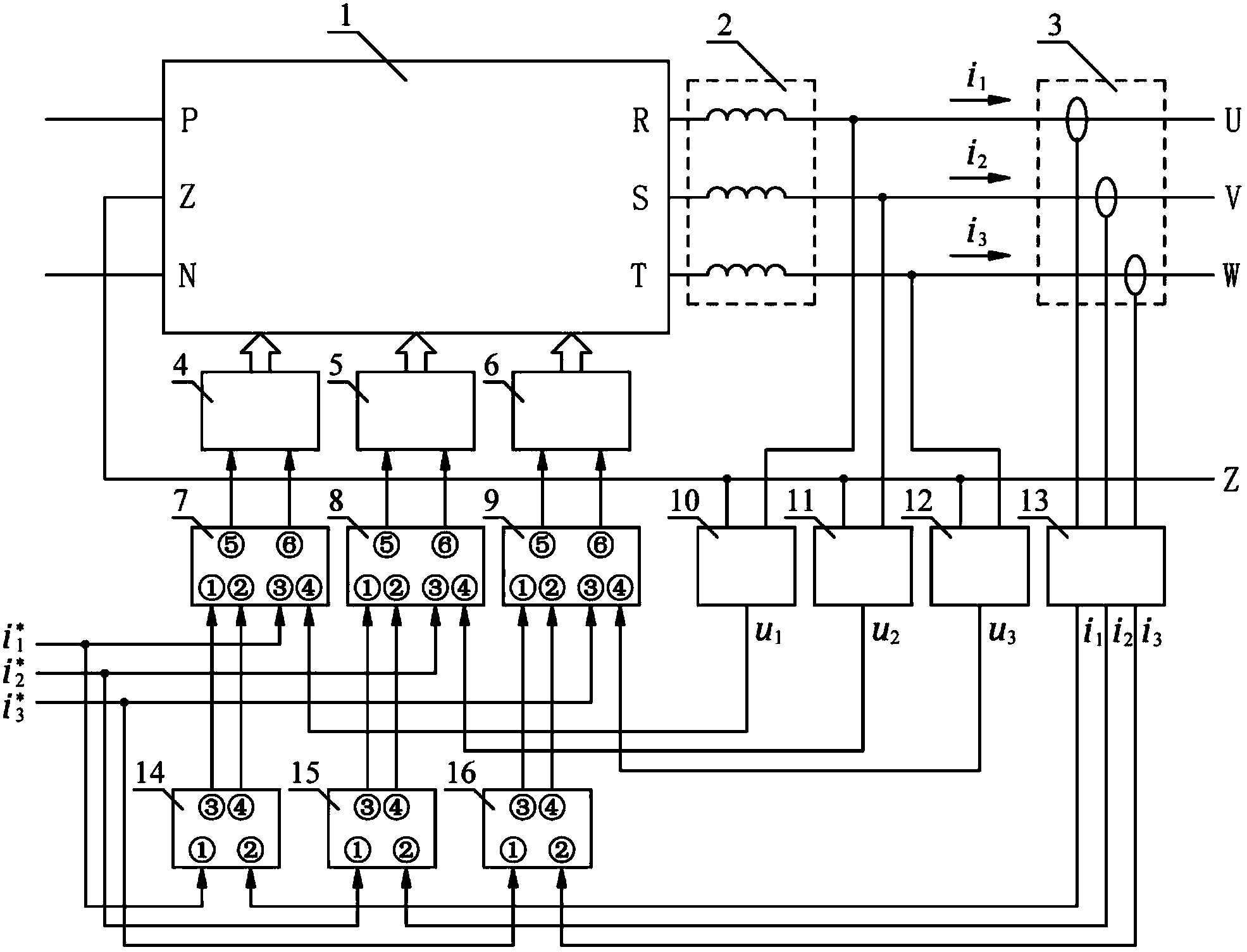

[0082] A three-level hysteretic current tracking inverter, such as figure 1 As shown, it includes a three-level inverter bridge 1, an inductor 2, a current sensor group 3, a first drive unit 4, a second drive unit 5, a third drive unit 6, a first drive control unit 7, a second drive unit Control unit 8, third drive control unit 9, first voltage detection unit 10, second voltage detection unit 11, third voltage detection unit 12, current detection unit 13, first hysteresis comparison unit 14, second hysteresis comparison unit Unit 15, the third hysteresis comparison unit 16, wherein:

[0083] The output terminals R, S and T of the three-level inverter bridge 1 are respectively connected to the three input terminals of the inductor 2, and the three output terminals of the inductor 2 are respectively connected to the three terminals of the three-level hysteresis current tracking inverter. Phase output U, V, W;

[0084] The two input terminals of the first voltage detection unit...

Embodiment 2

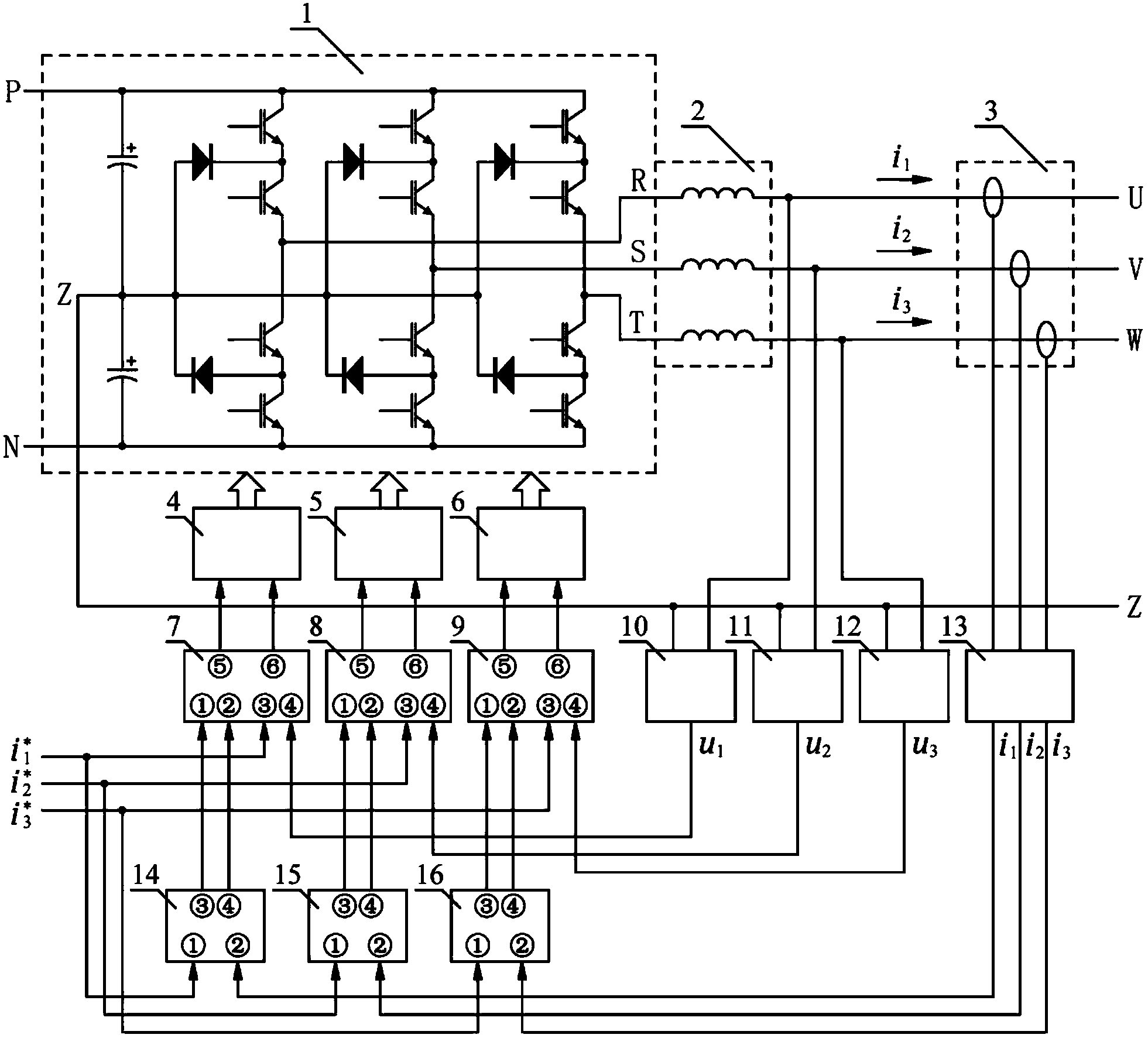

[0145] Such as figure 2 As shown, in this embodiment, the three-level inverter bridge 1 adopts the known diode-clamped three-level inverter bridge. At this time, the zero-level support point Z of the three-level inverter bridge is two The center connection point of the DC bus capacitors. Others are all the same as in Example 1.

Embodiment 3

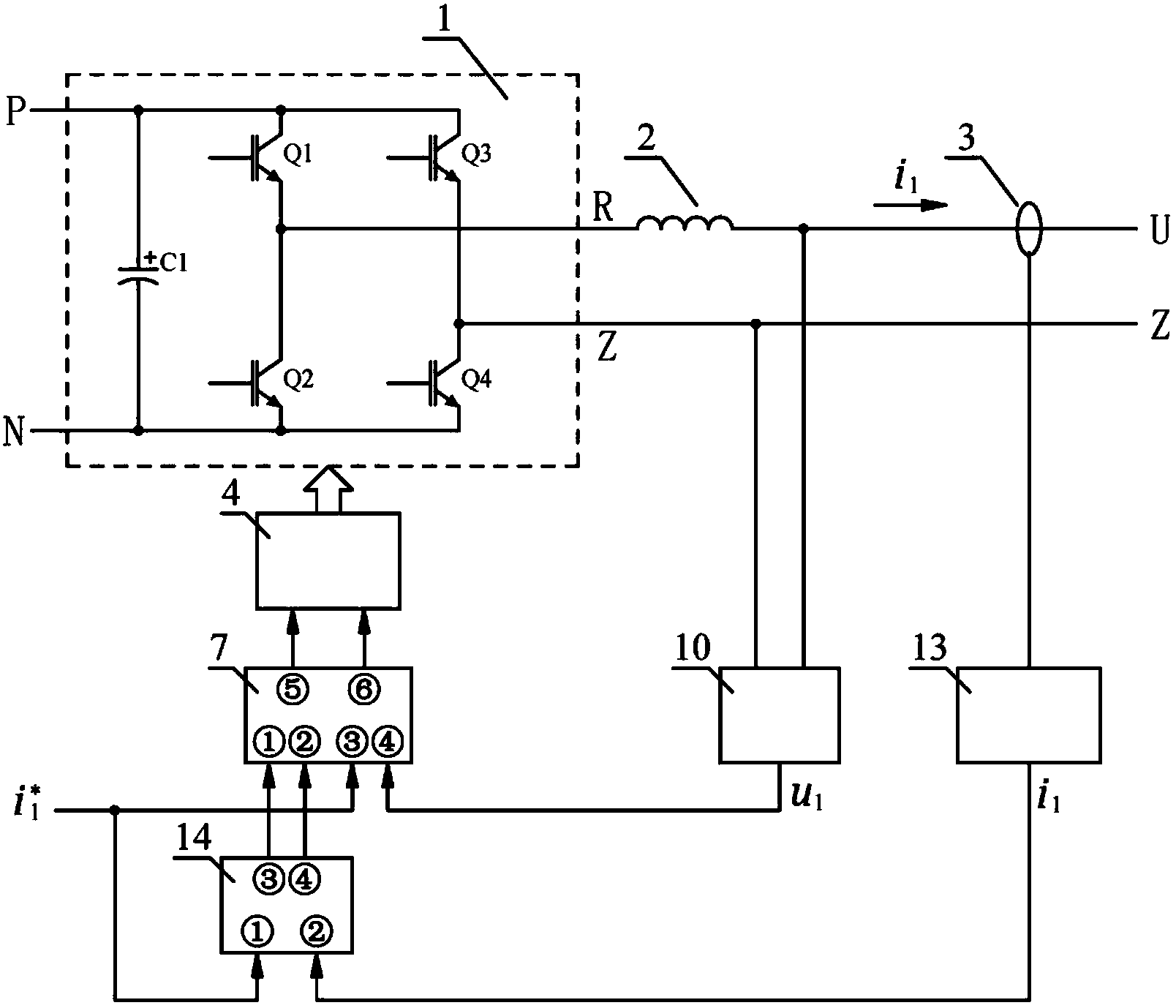

[0147] Such as image 3As shown, this embodiment is an application mode of the device and control method of the present invention in a single-phase inverter. In this embodiment, the three-level inverter bridge 1 adopts a well-known H-type single-phase inverter bridge. At this time, the zero-level support point Z of the three-level inverter bridge is an output terminal of the inverter bridge. Since only single-phase inversion is required, the second drive unit 5, the third drive unit 6, the second drive control unit 8, the third drive control unit 9, the second voltage detection unit 11, and the third voltage detection unit in the device 12. Both the second hysteresis comparison unit 15 and the third hysteresis comparison unit 16 can be deleted, the inductor 2 can be a single-phase inductor, only one current transformer is needed in the current sensor group 3, and the current detection unit 13 only needs to detect one For the phase current, only the variable corresponding to j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com