Method for preparing porous membrane based on segmented copolymer fibre micel

A technology of block copolymer and viscose, which is applied in the field of composite porous membrane preparation, can solve the problems of complicated membrane preparation process, reduced membrane flux, decreased controllability, etc. The effect of mass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

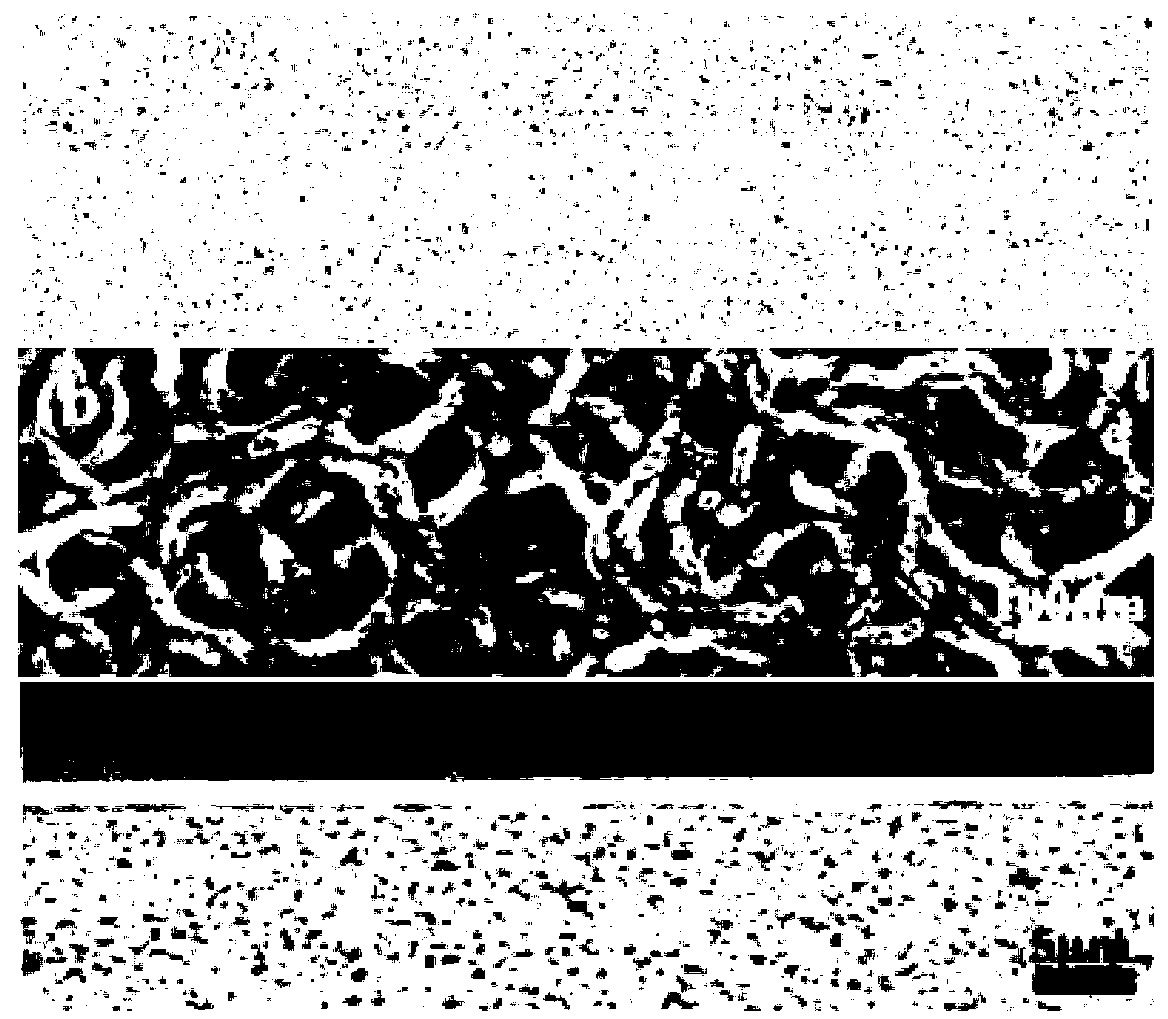

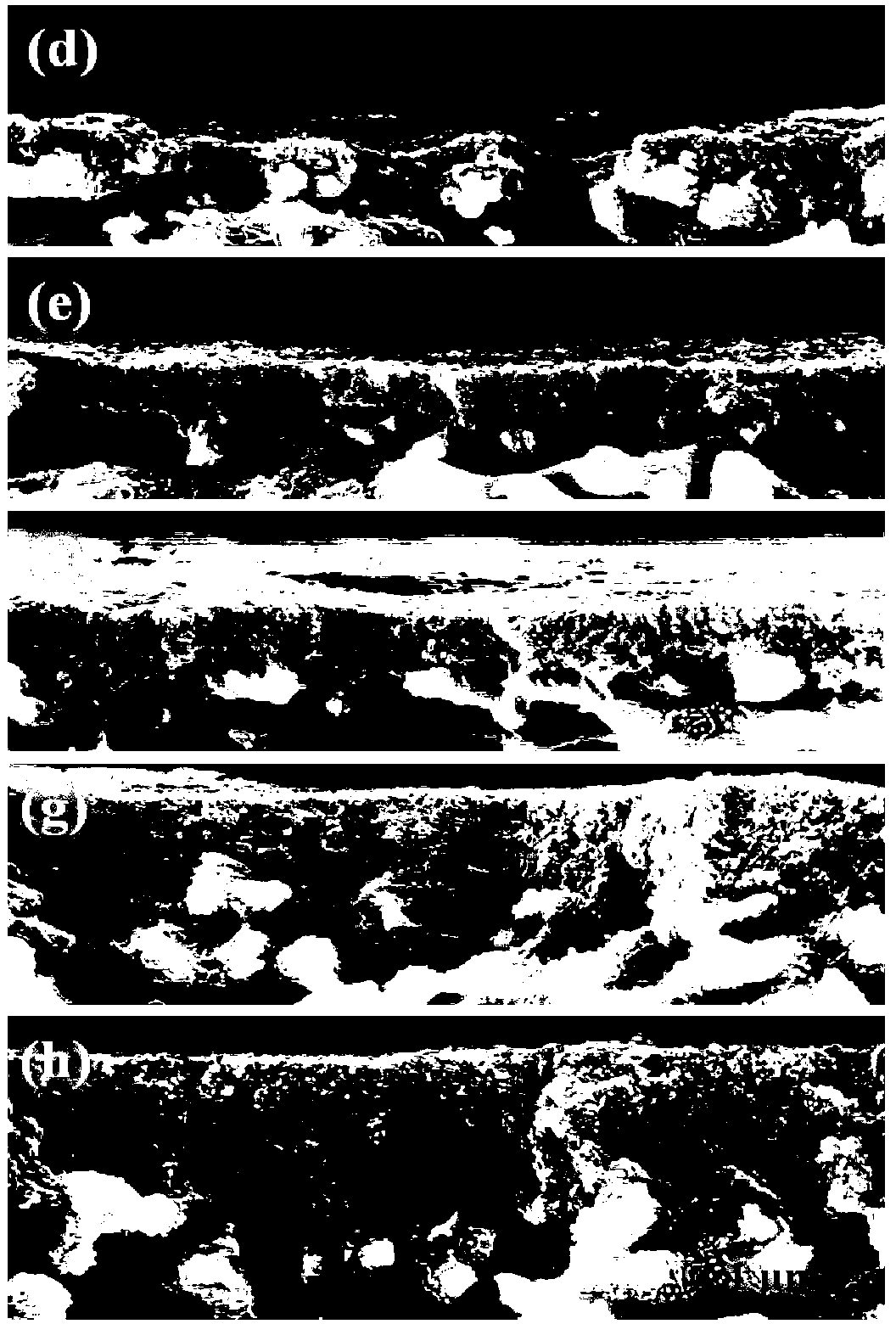

[0027] a) Weigh 0.02 g of polystyrene and poly(4-vinylpyridine) block copolymer fiber micelles (poly(4-vinylpyridine) accounts for 13% of the total volume of the block copolymer), fiber The micelles have a diameter of 27nm and a length of 2-4 microns, dispersed in 500 grams of ethanol, and prepared into a solution with a polymer mass fraction of 0.004%;

[0028] b) Take a piece of polyethersulfone (PES) membrane (the membrane area is about 4.1 square centimeters), soak it in water for 5 minutes, take it out, and then put it in the filter;

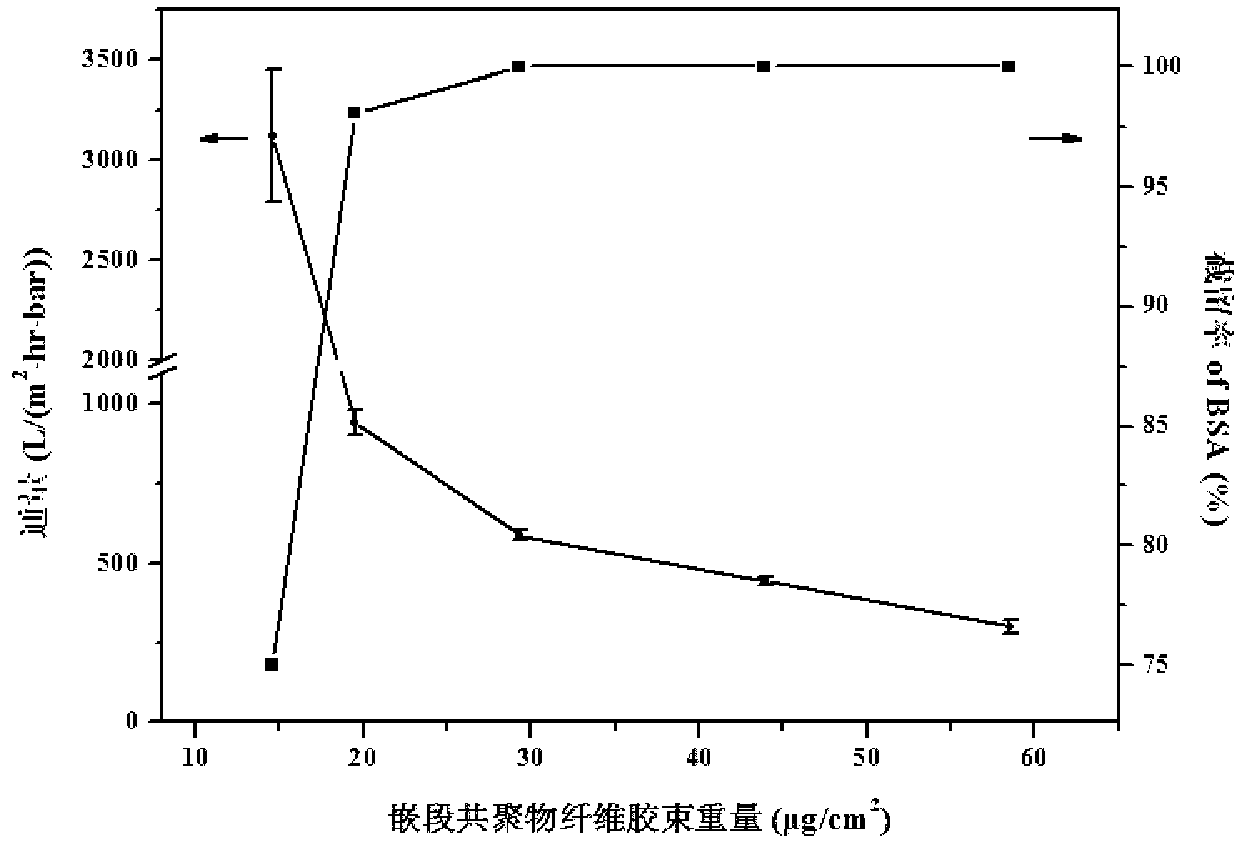

[0029] c) Take 1.5g, 2g, 3g, 4.5g, 6g of the prepared block copolymer fiber micelle solution, and filter it under a vacuum of 5kPa to evenly cover the surface of the PES membrane, that is, the embedded membrane covered on the base membrane. The amount of segment copolymer fiber micelles is 14.6 micrograms / square centimeter, 19.5 micrograms / square centimeter, 29.3 micrograms / square centimeter, 43.9 micrograms / square centimeter, and 58.5 micr...

Embodiment 2

[0036] a) Weigh 0.02 g of polystyrene and poly(4-vinylpyridine) block copolymer fiber micelles (poly(4-vinylpyridine) accounts for 9% of the total volume of the block copolymer), fiber The micelles have a diameter of 37nm and a length of 1-3 microns, dispersed in 100 grams of ethanol, and prepared into a solution with a polymer mass fraction of 0.02%;

[0037] b) Take a piece of nylon membrane (the membrane area is about 4.1 square centimeters), soak it in water for 3 minutes, take it out, and then put it in the filter;

[0038] c) Take 1 gram of the prepared block copolymer fiber micelle solution, and filter it under a vacuum of 1kPa to evenly cover the surface of the nylon membrane, that is, the amount of block copolymer fiber micelles covered on the base film is 48.8 μg / square cm;

[0039] d) The microfiltration base membrane filtered with the block copolymer fiber micelles solution is placed in the air to dry naturally, and a composite porous membrane with closely packed ...

Embodiment 3

[0042] a) Weigh 0.4 g of polystyrene and poly(2-vinylpyridine) block copolymer fiber micelles (poly(2-vinylpyridine) accounts for 11% of the total volume of the block copolymer), fiber The micelles have a diameter of 47nm and a length of 1-5 microns, dispersed in 100 grams of water, and prepared as a solution with a polymer mass fraction of 0.4%;

[0043] b) Take a piece of polyvinylidene fluoride membrane (the membrane area is about 4.1 square centimeters), soak it in water for 10 minutes, take it out, and then put it in the filter;

[0044]c) Take 61.5 grams of the prepared block copolymer fiber micelles solution, and filter it under a vacuum of 10kPa to evenly cover the surface of the polyvinylidene fluoride membrane, that is, the amount of block copolymer fiber micelles covered on the base film is 60 μg / cm²;

[0045] d) The microfiltration base membrane filtered with the block copolymer fiber micelle solution is placed in the air to dry naturally, and the closely packed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com