Combined conveniently-detached tool for multi-jaw waste material breaker

A crusher and waste technology, applied in the direction of grain processing, etc., can solve the problems of high maintenance cost, high material requirements, waste of resources, etc., and achieve the effect of reducing the use cost, reducing the manufacturing cost and improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

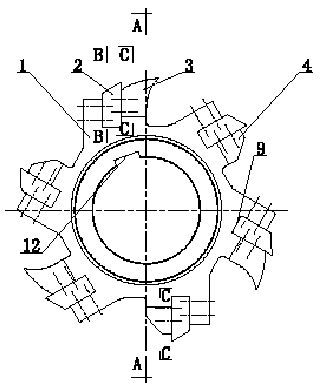

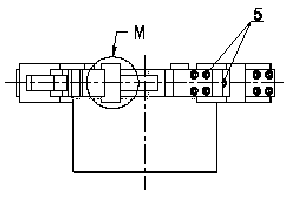

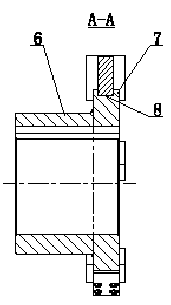

[0017] Rotary knife seat 1 is to process the knife seat 7 and the spacer 6 into one; there are bolt holes 11 on the hook knife 3 and the cutter 2 respectively, which are connected by hexagon socket head cap screws 5 to form an assembly;

[0018] Bolt holes 11 are respectively opened on the bumper 4 and the cutter 2, and are connected into assemblies with hexagon socket head cap screws 5;

[0019] There are card slots 8 and 9 on the rotary knife seat 1 and card slots 10 and bolt holes 11 on the cutter 2;

[0020] Combine 2-4 cutter assemblies with hook knives, and 2-4 Knife collision The cutter assembly is engaged with the draw-in groove 8 and the draw-in groove 9 on the rotary knife seat respectively through the card slot 10 on the cutter; and is evenly distributed along the circumference of the rotary knife seat; and then connected and fastened with the hexagon socket head cap screw 5;

[0021] After the combined detachable tool is assembled, it is connected with the main s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap