High-power light emitting diode (LED) lamp heat dissipating device

A technology of LED lamps and heat sinks, which is applied to lighting devices, cooling/heating devices of lighting devices, components of lighting devices, etc., which can solve the problems of large space occupation, poor reliability, and heat accumulation effect of light sources Convenience and ease of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

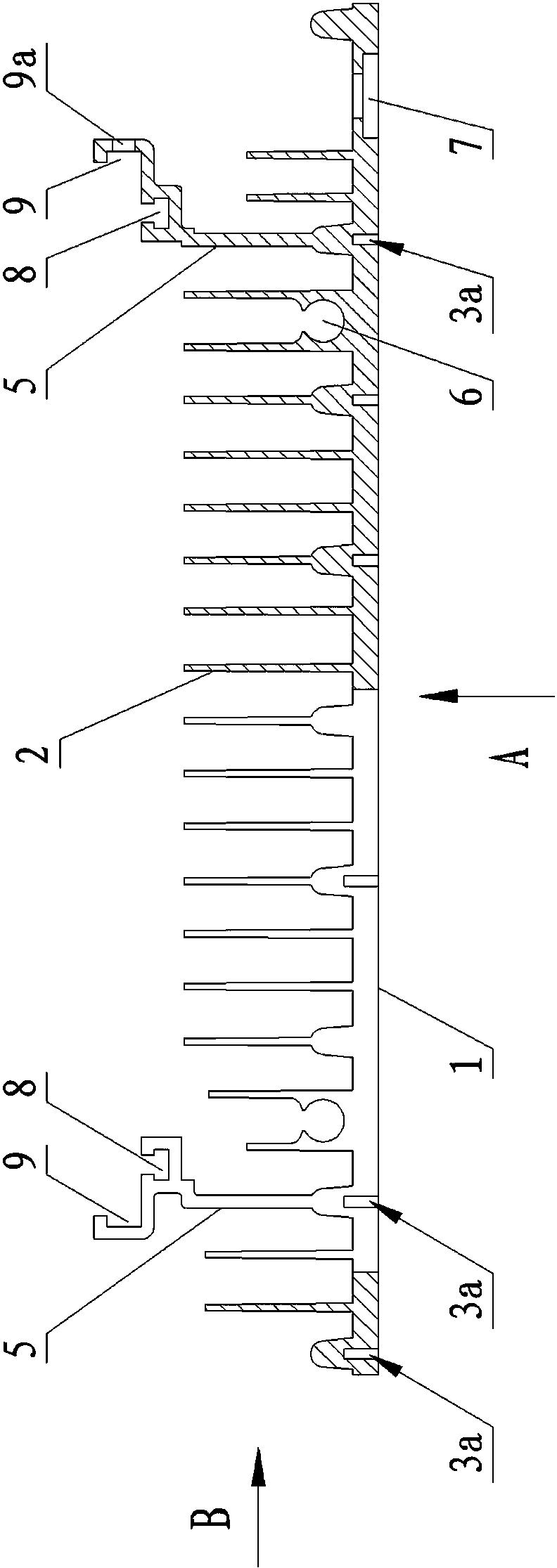

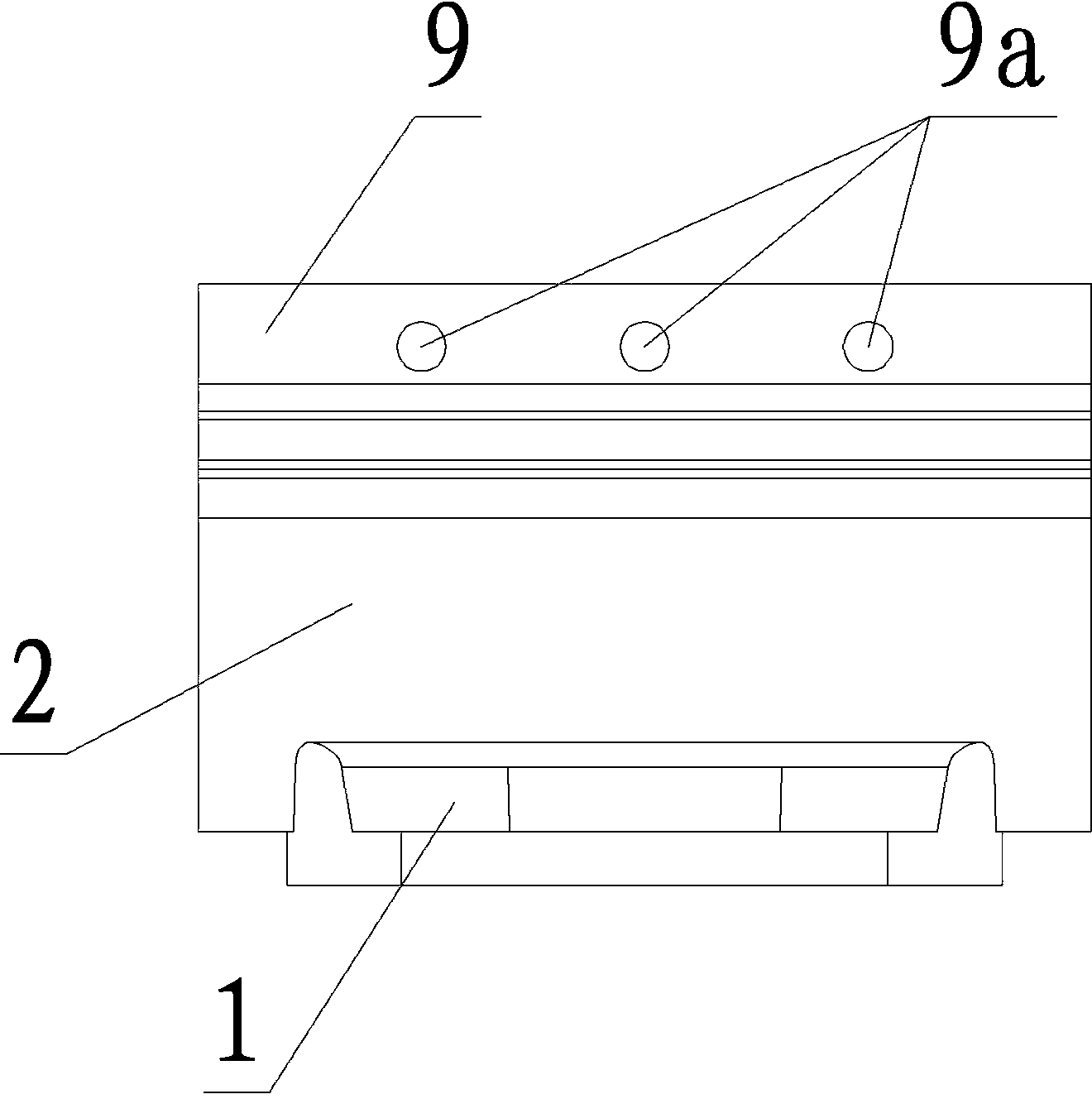

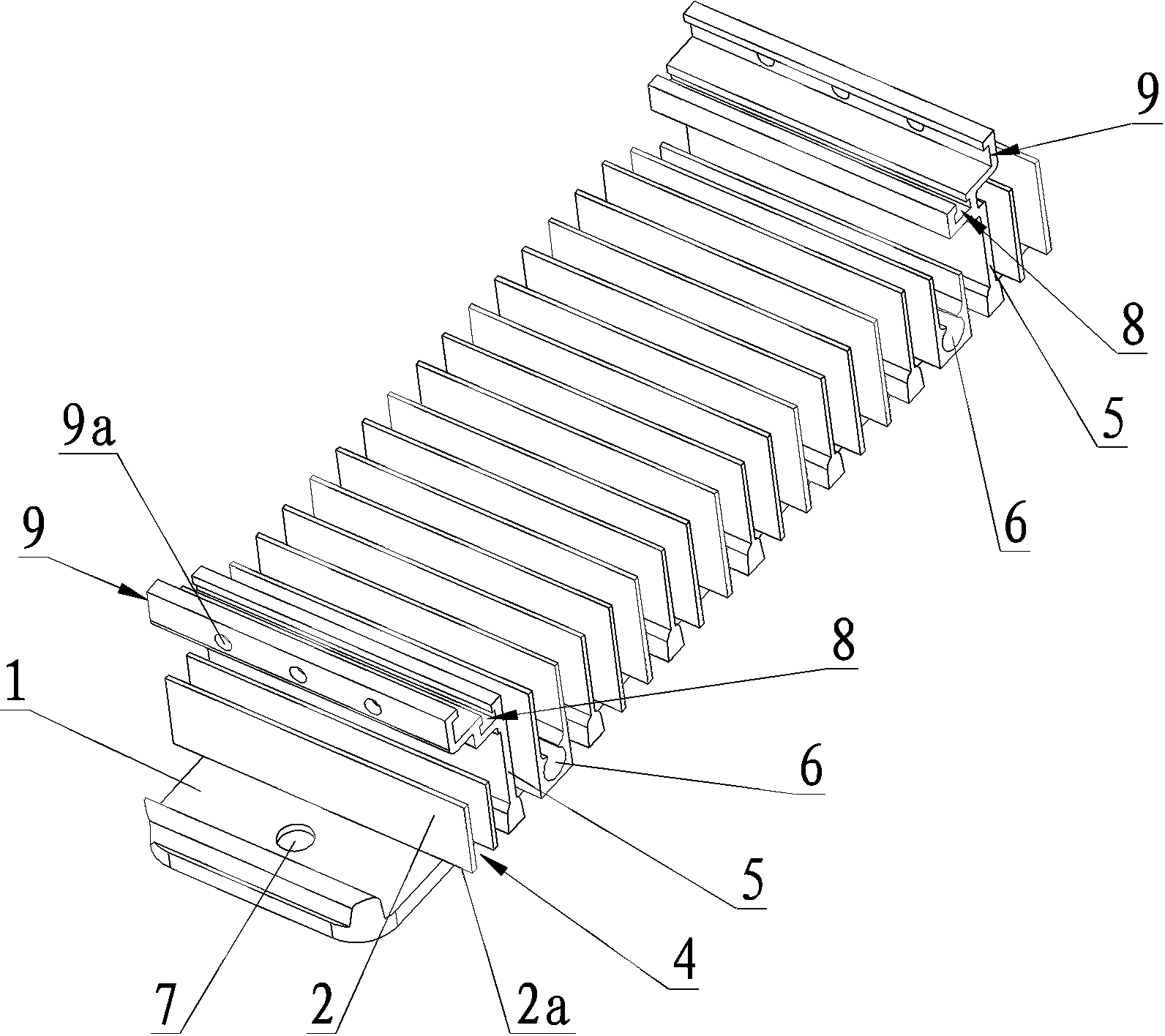

[0019] see Figure 1 to Figure 4 , a heat dissipation device for high-power LED lamps, comprising a base plate 1 with a plurality of heat sinks 2 on one side, the heat sinks 2 are perpendicular to the base plate 1, and the distance between two adjacent heat sinks is > 10mm, which can not only improve heat dissipation efficiency, but also It also prevents the accumulation of dust and oil. One side of the substrate 1 is an installation surface 3 for installing LED lamps. The installation surface 3 is provided with several installation screw holes 3a, and the several installation screw holes 3a include a lamp board fixing hole 3a1 arranged along the transverse centerline of the installation surface 3 and the lampshade fixing holes 3a2 arranged around the installation surface 3 are respectively used to install the lamp board and the lampshade of the LED lamp, so that the lamp board and the lampshade of the LED lamp can be detachably installed through the lamp board fixing hole 3a1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com