Conducting cable connector

A technology of conductive cables and conductive connection blocks, applied in conductive connection, connection, clamping/spring connection, etc., can solve the problems of weak tolerance, easy damage of screw teeth, connection failure, etc., to achieve easy production and connection. Strong, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A number of technical solutions of the present invention will be further described below in conjunction with the accompanying drawings:

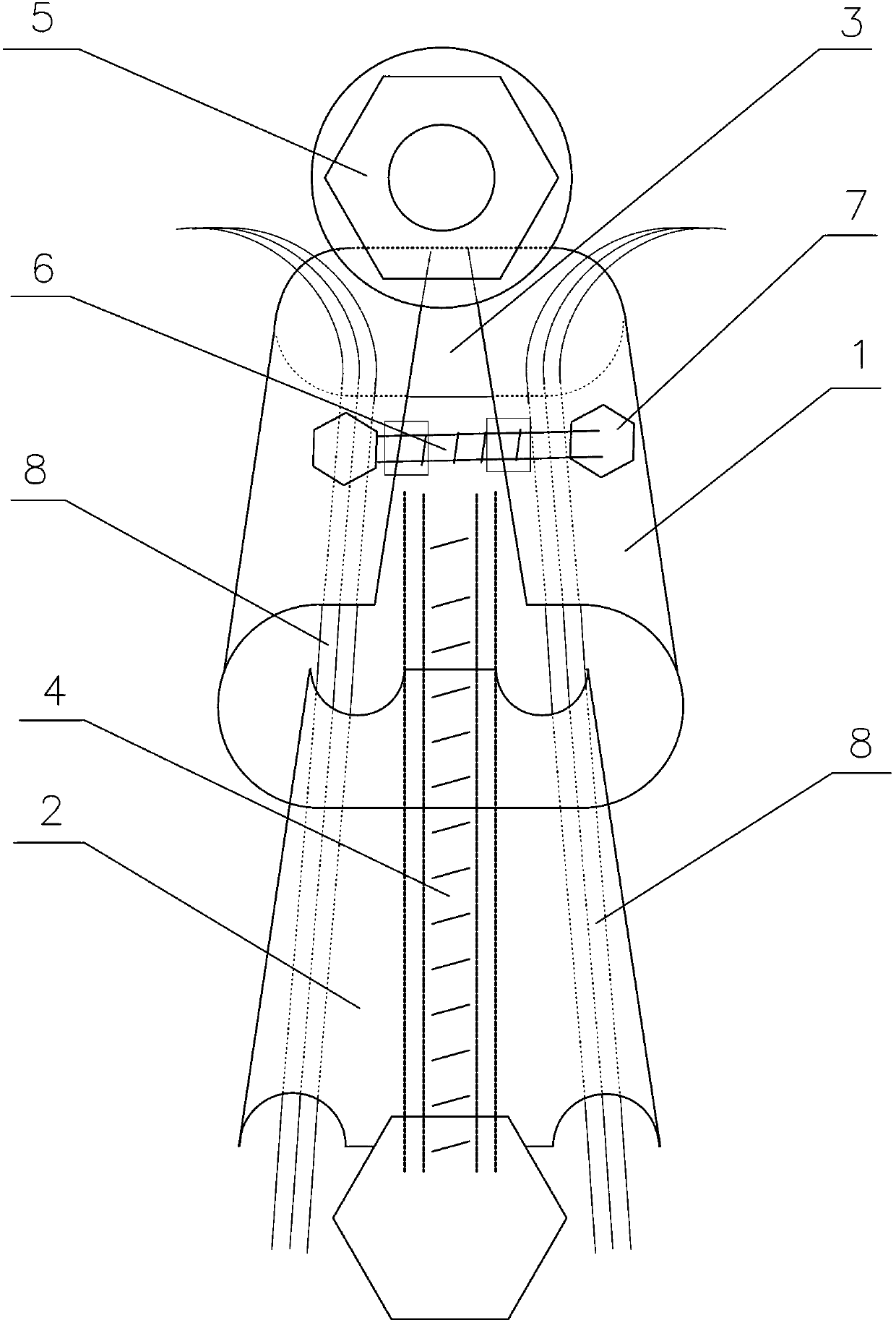

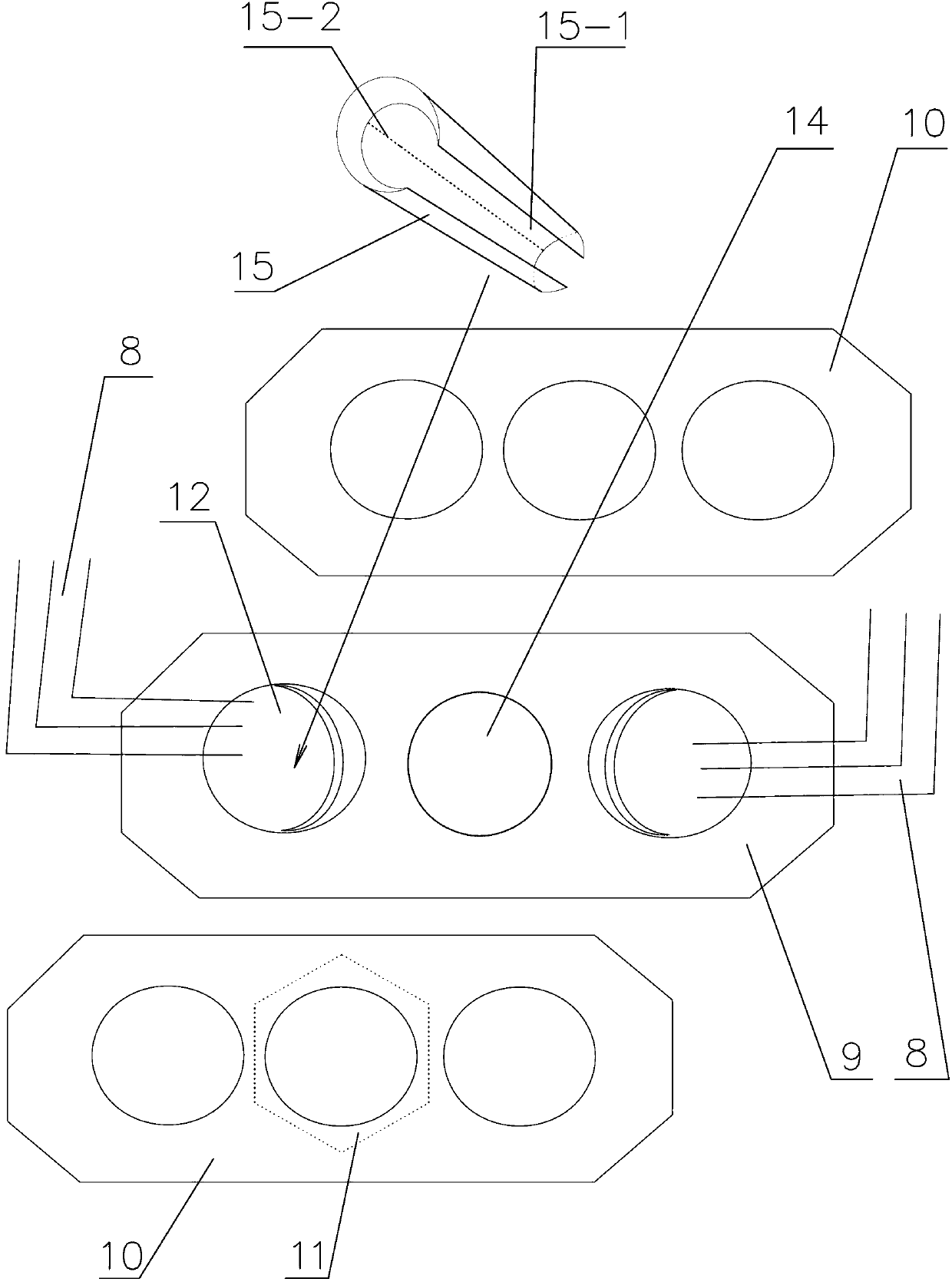

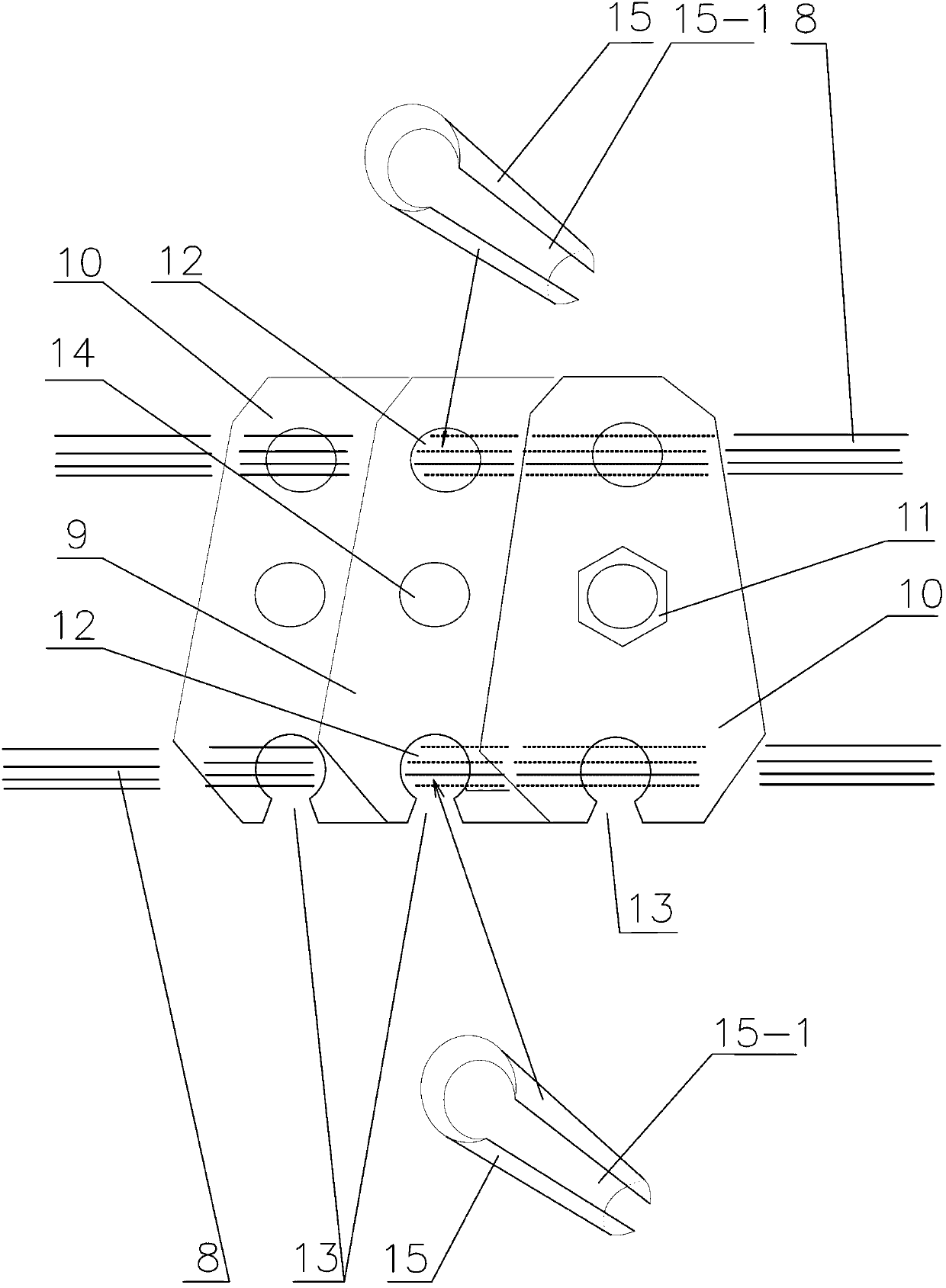

[0033] 1. The clamping part of the conductive cable connector of the present invention is a flat conductive inner cone sleeve 1 and a conductive outer cone sleeve 2 with outer arcs on both sides, and the conductive inner cone sleeve 1 is nested in the conductive outer cone sleeve 2 In the inner taper hole of the conductive outer tapered sleeve 2, an axial wire core enters the groove 3 on the upper plane of the conductive outer tapered sleeve 2, and the upper plane of the conductive outer tapered sleeve 2 on both sides of the conductive outer tapered sleeve 2 where the wire core enters the groove 3 is fixed with lugs. Set up a piercing hole; the squeeze bolt 4 is axially pierced in the conductive inner taper sleeve 1 and the conductive outer taper sleeve 2, the squeeze bolt 4 is screwed with the squeeze nut 5, and the hexagonal head of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com