Coal ash collecting fractionation device

A technology of fractional separation and fly ash, which is applied in the direction of solid separation, separation of solids from solids by air flow, and sustainable waste treatment. It can solve the problems of insufficient advanced applicable technology and low utilization rate of high added value, and achieve Simple structure, fast settling and separation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

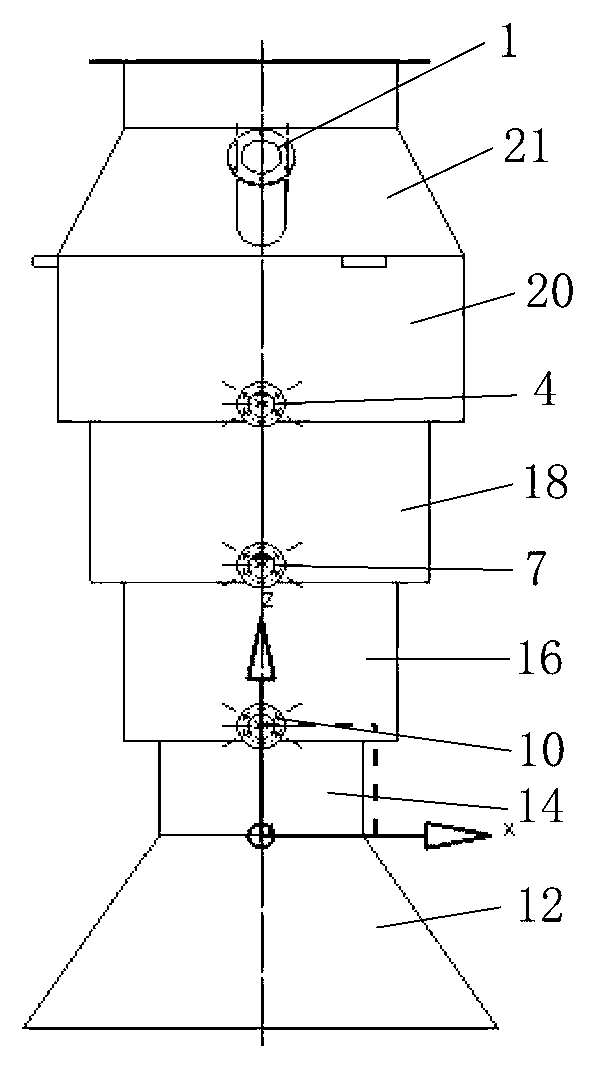

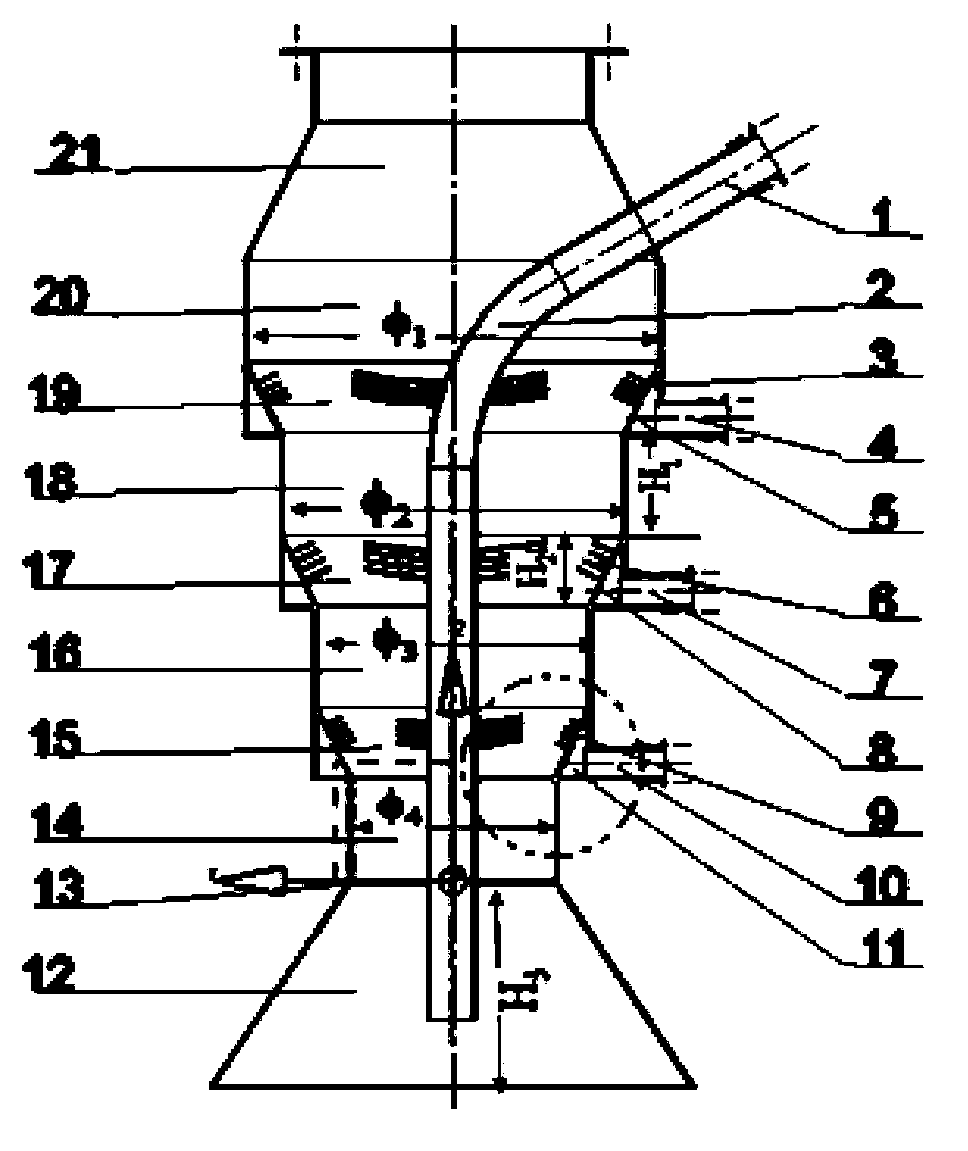

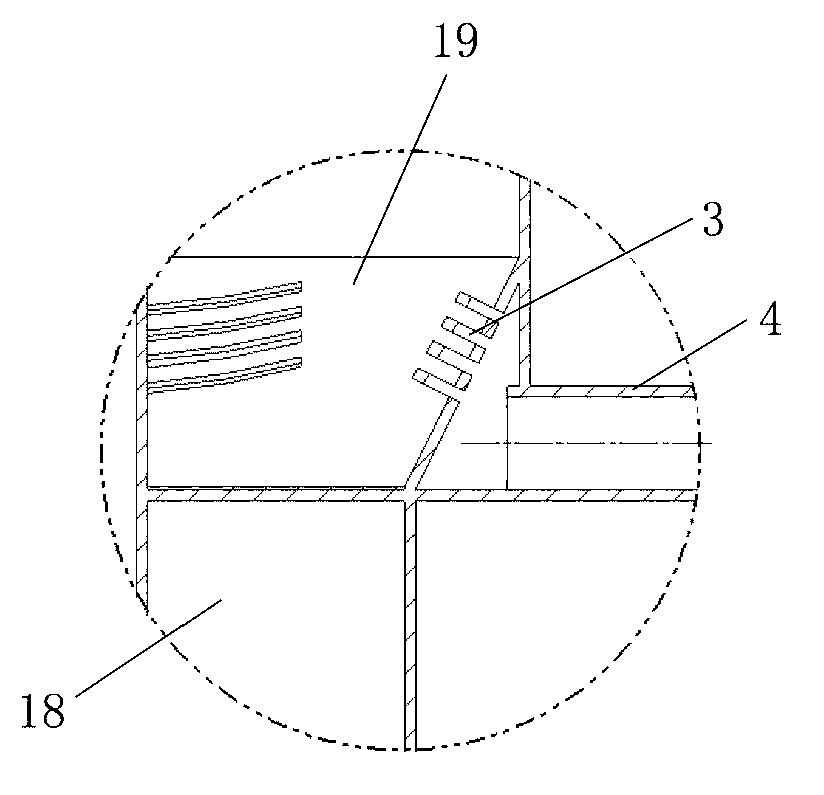

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0028] Such as Figures 2 to 5 As shown, the device includes an air jet pipeline, a discharge pipe, a dust cover, a triangular storage chamber, a louvered channel, a stepped pipeline, and a suction pipe. The air jet pipeline is composed of spoiler pipe 2 and intake pipe 1. The elbow end of spoiler pipe 2 is welded on the channel reserved by the pipe body of suction pipe 21, and the pipe body of spoiler pipe 2 passes through suction pipe 21. Stretch into the stepped pipeline, and extend into the dustproof cover 12 along the center line of the stepped pipeline. The spoiler tube 2 is welded to the lower end of the suspension chamber 14 through a cross-shaped spoiler tube fixing frame 13 , and the disturbed air outlet is slightly higher than the bottom of the dust cover 12 .

[0029] One end of the inlet pipe 1 is connected to the air outlet pipe of the air comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com