Method for manufacturing propeller shaft special for ship with electro slag remelting-fusion welding process

A marine propeller and electroslag remelting technology, which is applied in the field of heavy equipment manufacturing, can solve the problems of low material utilization, high production power consumption, environmental pollution, etc., and achieve high material utilization, low cost, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

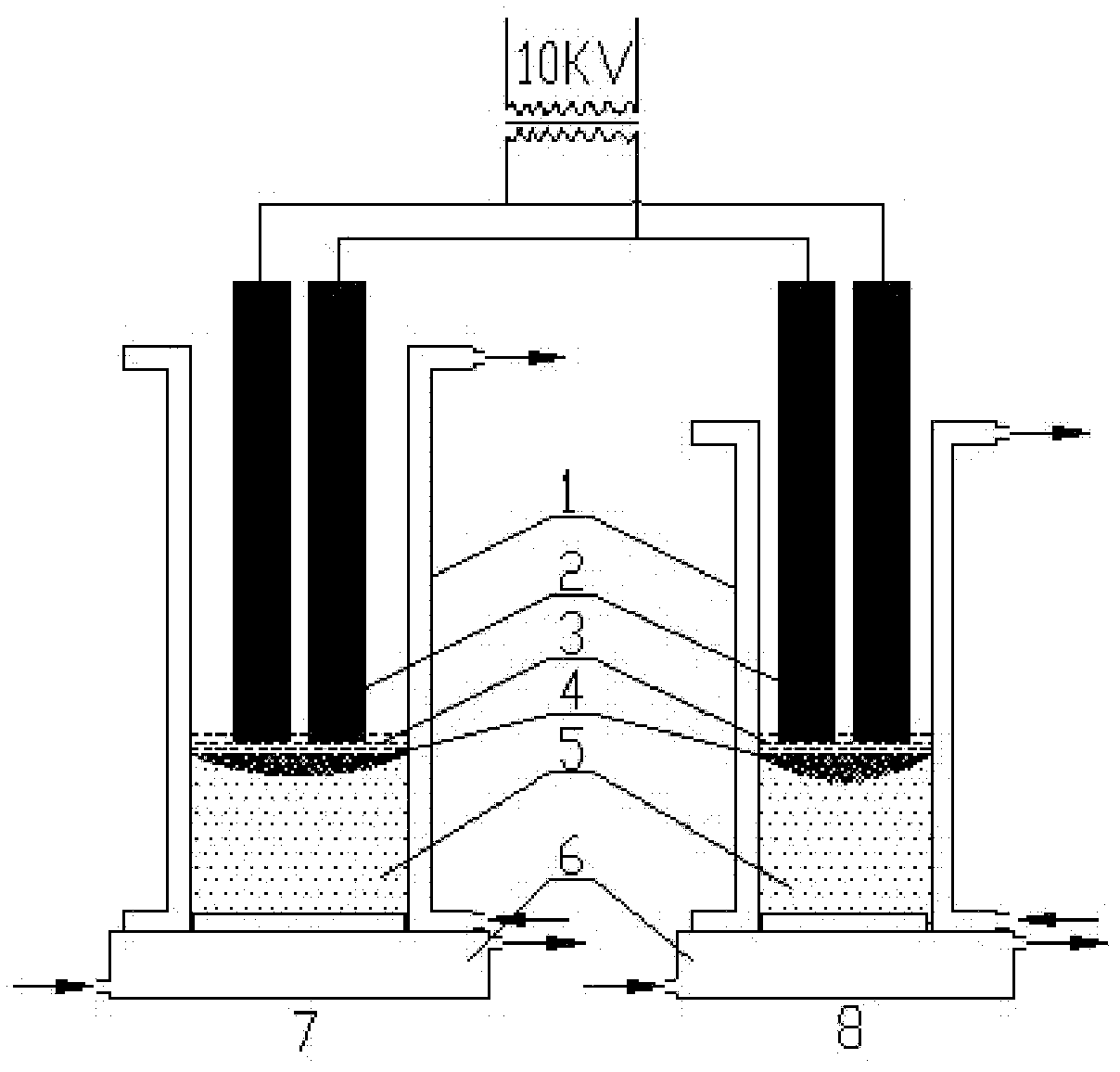

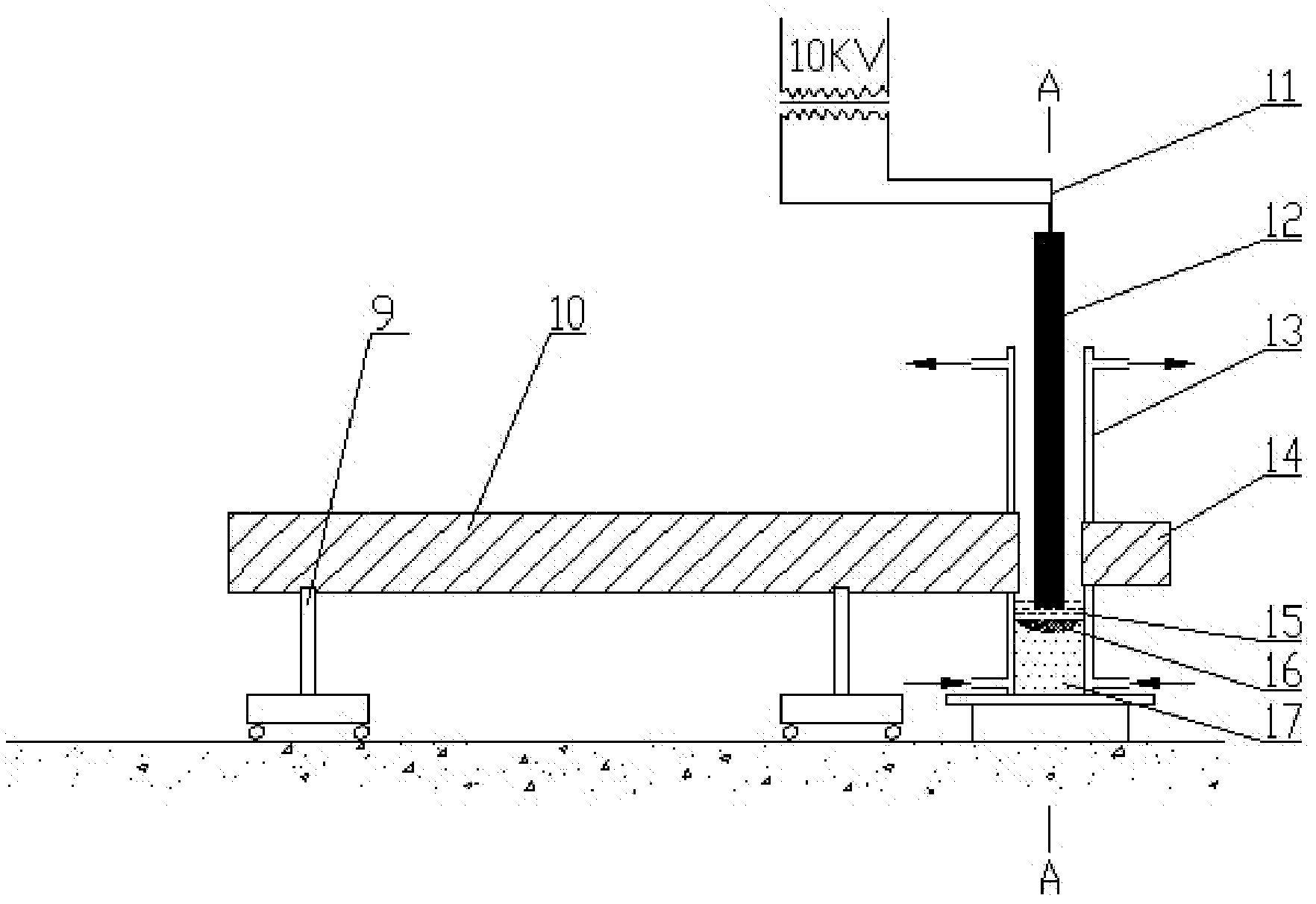

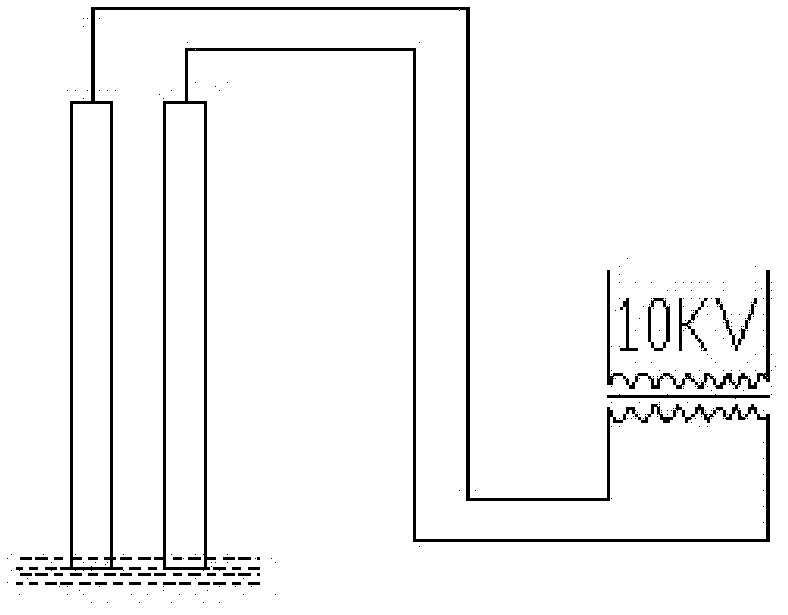

[0028] Embodiment 1: a kind of method of manufacturing marine propeller shaft with electroslag remelting-fusion welding process is characterized in that it comprises electroslag remelting process and electroslag welding process (see Figure 1-3 ), which consists of the following steps:

[0029] (1) Adjust and install the special-shaped copper water-cooled crystallizer I1;

[0030] (2) Insert the two ends of the two consumable electrodes I2 into the crystallizer I1;

[0031] (3) adding the pre-dried and melted ternary slag system I3 into the crystallizer I1;

[0032] (4) Power transmission, the current is connected to the ternary slag system I3 through the consumable electrode I2, and the slag pool completes the conversion of electric energy and heat energy through the current, and controls the outlet water temperature of the crystallizer I1 to not exceed 70°C;

[0033] (5) The consumable electrode I2 slowly melts in the ternary slag system I3 to form molten steel droplets, a...

Embodiment 2

[0047] Embodiment 2: a kind of method of manufacturing marine propeller shaft with electroslag remelting-fusion welding process is characterized in that it comprises electroslag remelting process and electroslag welding process (see Figure 1-3 ), which consists of the following steps:

[0048] (1) Adjust and install the special-shaped copper water-cooled crystallizer I1;

[0049] (2) Insert the two ends of the two consumable electrodes I2 into the crystallizer I1;

[0050] (3) adding the pre-dried and melted ternary slag system I3 into the crystallizer I1;

[0051] (4) Power transmission, the current is connected to the ternary slag system I3 through the consumable electrode I2, and the slag pool completes the conversion of electric energy and heat energy through the current, and controls the outlet water temperature of the crystallizer I1 to not exceed 70°C;

[0052](5) The consumable electrode I2 slowly melts in the ternary slag system I3 to form molten steel droplets, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com