Horizontal quantitative prepressing type large-scale garbage compressor

A garbage compressor, a horizontal technology, applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of insufficient water extrusion, low garbage density, and low squeezing capacity, so as to improve the compactness of garbage and improve the quality of garbage. storage capacity and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

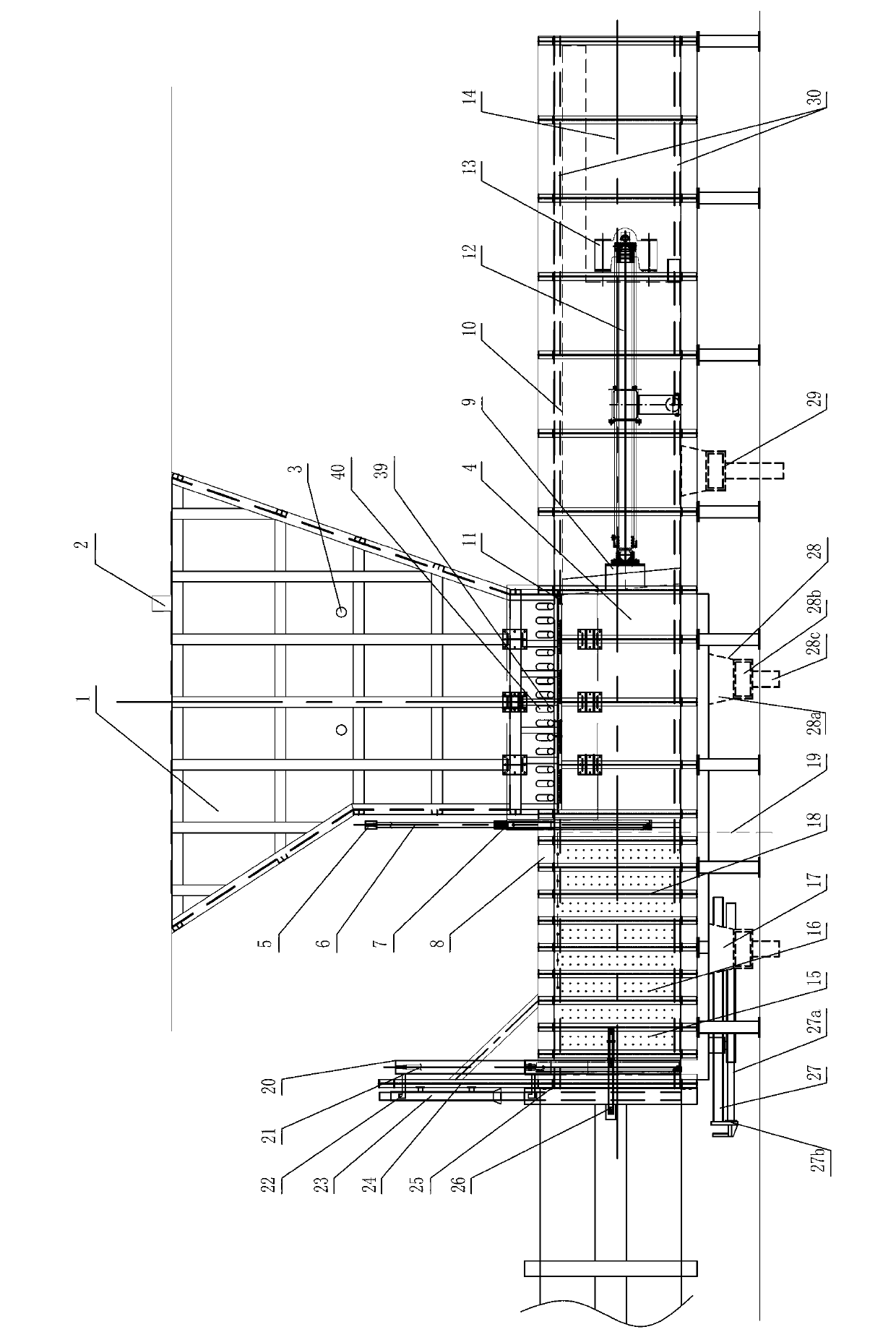

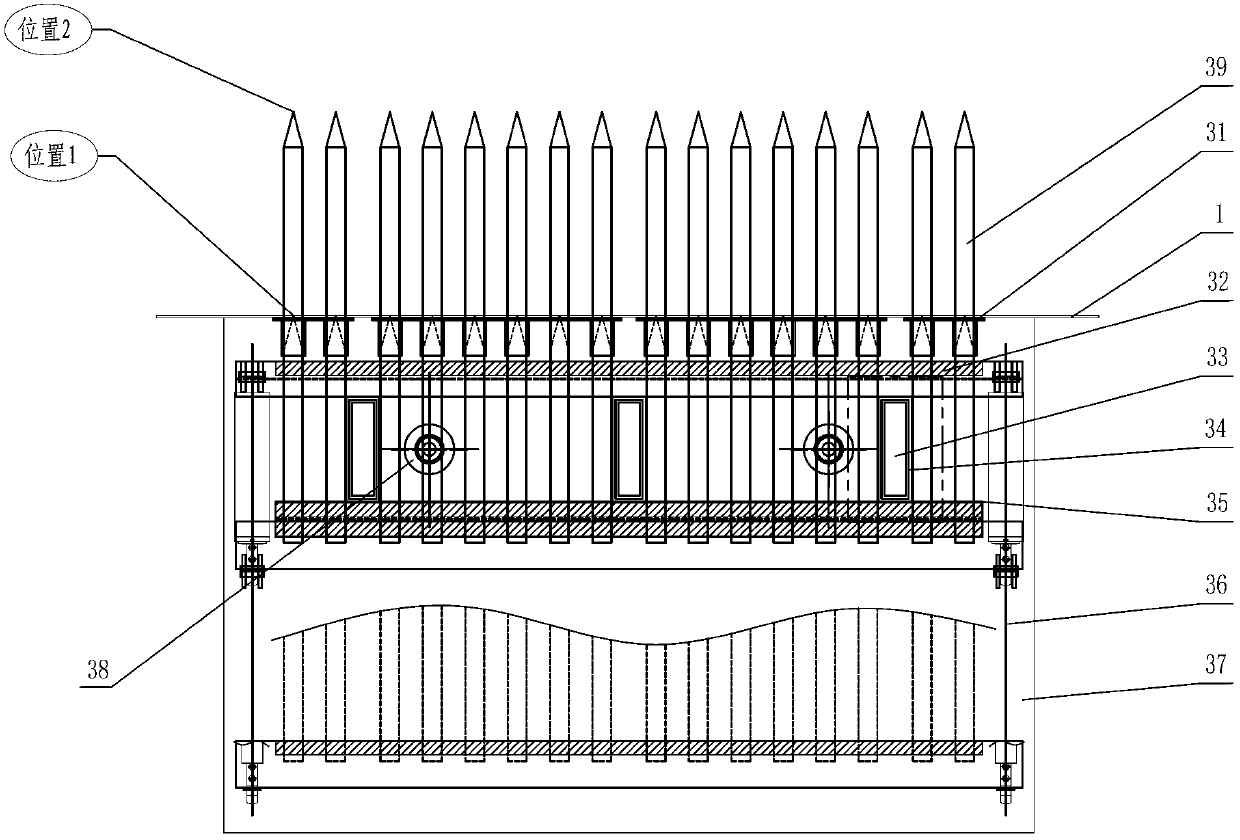

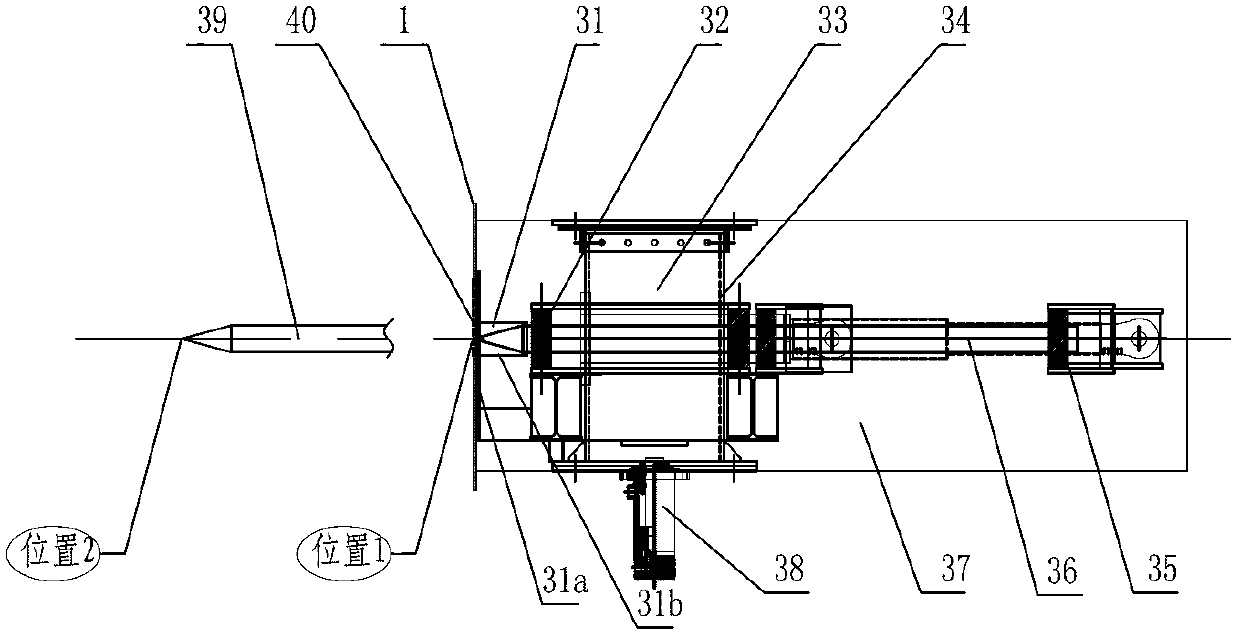

[0030] As shown in the figure: the horizontal quantitative preloading type large garbage compressor in the embodiment mainly includes a frame 8 on which a storage bin 1, a feeding bin 4, a compression bin 15 and a hydraulic bin 14 are arranged.

[0031] Such as figure 1 As shown, the storage bin 1 is located on the upper part of the frame 8, and the top of the storage bin 1 is provided with an open upper mouth for pouring the garbage to be compressed. In order to enable the poured garbage to slide down smoothly, the side wall of the storage bin 1 on the side close to the dumping side is an inclined wall inclined from bottom to top. In order to accurately place the garbage truck and avoid danger, a car limit 2 is provided at the upper mouth of the storage bin 1; in order to realize the quantitative measurement of garbage, a detector 3 is provided on the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com