Polyester film and application thereof

A polyester film and polyester technology, applied in the field of polyester film, can solve the problems of poor water resistance, affect polyester characteristics, and easily become brittle materials, and achieve improved refractive index performance, high heat resistance, and high refraction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

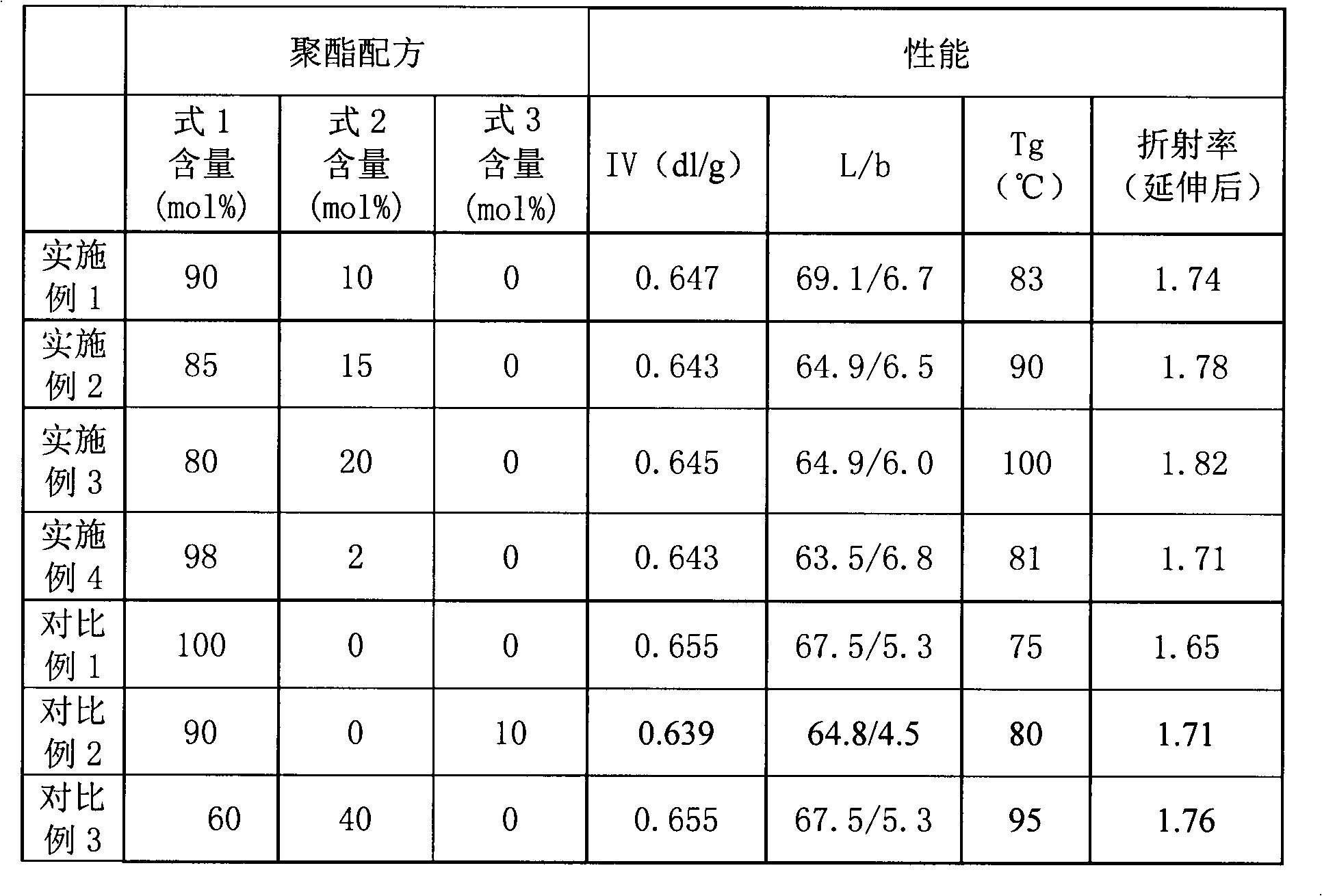

Examples

Embodiment 1

[0035] The polyester composition is a copolymer obtained by the esterification reaction of terephthalic acid, ethylene glycol and 4,4'-dicarboxydiphenyl sulfone.

[0036] Concrete reaction process is as follows:

[0037] At a temperature of 250°C, 166 parts (weight) of terephthalic acid and 64.2 parts (weight) of ethylene glycol and 28.8 parts (weight) of 4,4'-dihydroxydiphenyl sulfone (Haining Huangshan Chemical Co., Ltd.) Direct esterification reaction, the above reaction is completed, and a small molecule polymer is obtained.

[0038] Add catalyst antimony trioxide compound Sb to the above-mentioned small molecule polymer 2 o 3 The addition amount of Sb in the middle is 200ppm, the addition amount of magnesium acetate is 55ppm (relative to the weight of polyester), and the phosphorus stabilizer triethylphosphonoacetate TEPA70ppm (relative to the weight of polyester). Under atmospheric pressure, the pressure is reduced to about 300Pa in 1 hour, and the temperature is rais...

Embodiment 2

[0041] 166 parts by weight of terephthalic acid, 60.6 parts by weight of ethylene glycol and 43.2 parts by weight of 4,4'-dihydroxydiphenylsulfone (Haining Huangshan Chemical Co., Ltd.) were subjected to direct esterification. All the other are the same as embodiment 1.

Embodiment 3

[0043] 166 parts by weight of terephthalic acid, 57.1 parts by weight of ethylene glycol and 57.5 parts by weight of 4,4'-dihydroxydiphenyl sulfone (Haining Huangshan Chemical Co., Ltd.) were subjected to direct esterification. All the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com